About Us

HSXD: Innovating Paper Mill Roller Technology

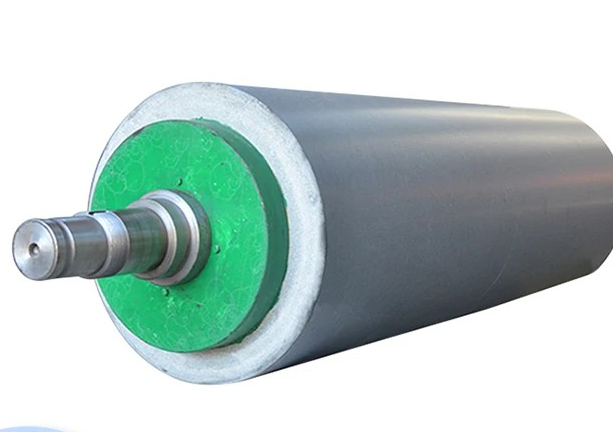

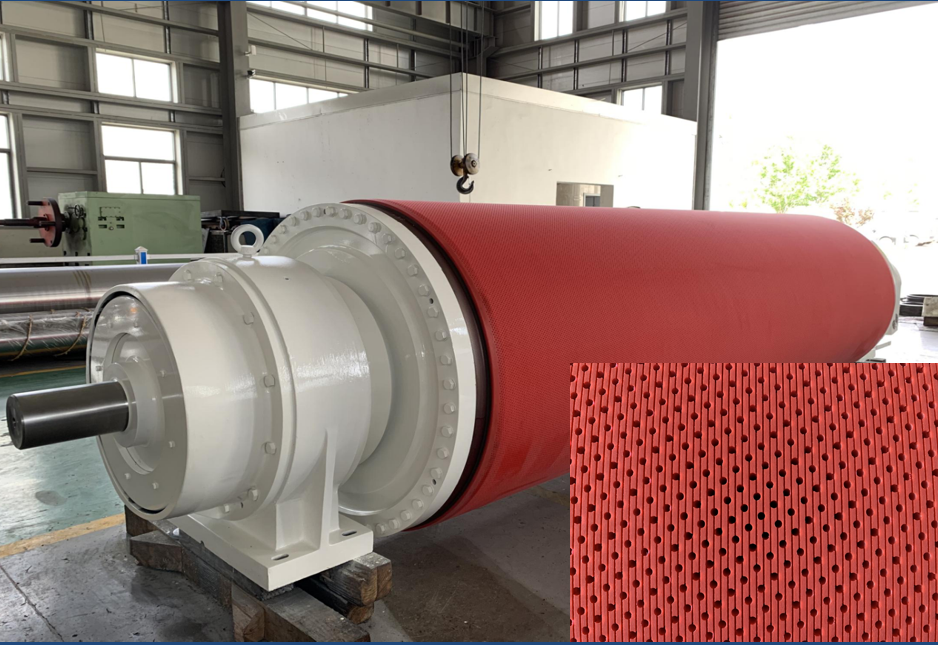

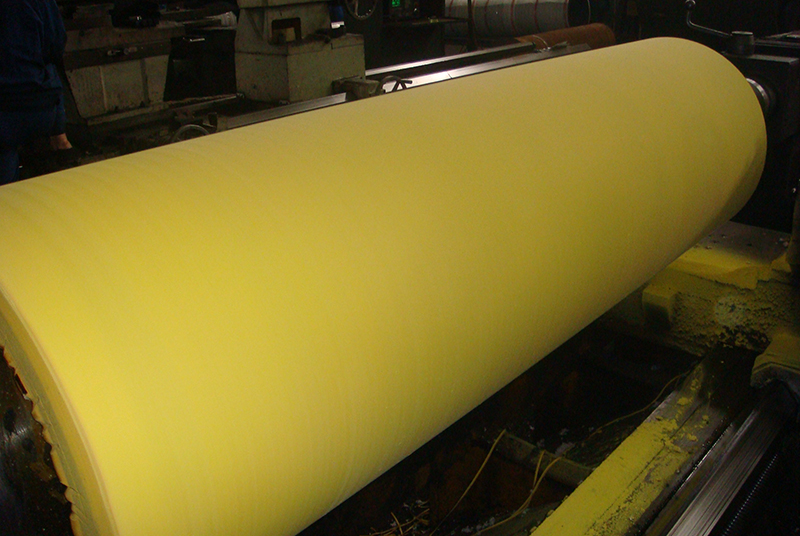

"Hs Machinery, a premier paper mill rolls manufacturer based in Shandong, China, brings over 27 years of dedicated expertise to the paper industry. We are a professional manufacturer of high-performance paper machine rollers, including specialized granite stone rolls, durable PU rollers, precision hard chrome rollers, reliable glue rollers, and versatile rubber rollers. Our commitment to quality is evident in every paper making machine roller we produce, all proudly made in China and adhering to sustainable manufacturing practices. As a leading supplier of natural granite pressing stone rolls, our continuous technological advancements ensure we deliver a wide range of customized roller solutions tailored to your specific paper production needs. Whether you require Stone Rolls, PU Roll...

- 30+ Countries served worldwide

- Professional engineers & technicians

- +8613805366551 24/7 service hotline

Industry Leaders in Paper Machine Roll Manufacturing with Two Decades of Experience - Trusted by Global Enterprises for Reliable Quality and Superior Service

Paper Machine Rolls: Core Advantages

High-Performance Paper Machine Rolls, Custom-Engineered for Intensive Paper Production

Every Paper Machine Roll we supply – be it a Press Roll, Guide Roll, Sizing Roll, or Dryer Cylinder – utilizes premium industrial materials and precision manufacturing processes. These Paper Mill Rollers are engineered for the rigorous demands of high-speed paper production lines, ensuring optimal operational efficiency and extended service life across diverse pulp and paper applications. Our heavy-duty rolls offer excellent wear resistance and corrosion resistance, a reliable guarantee for enhancing your paper quality and production stability.

Boosting Paper Mill Efficiency & Output: Driven by Our Expert Paper Mill Roller Technology

Choosing our Rolls for the Paper Industry means opting for higher production efficiency and greater paper output. Our roller solutions are dedicated to optimizing your papermaking process, reducing unscheduled downtime, and improving Overall Equipment Effectiveness (OEE). From roll surface treatment to dynamic balancing, every detail is crafted to maximize throughput and deliver superior paper products from your papermaking equipment. Our high-performance roll components are key to maintaining your lead in the competitive paper market.

Customized Paper Machine Roll Design & Cost-Effective Procurement Solutions

We understand that every paper mill has unique process parameters and paper grade requirements. Therefore, we offer comprehensive customized Paper Machine Roll services, from roll body design to bearing selection, ensuring a perfect match for your specific applications. Concurrently, we provide competitive industrial roll pricing and flexible bulk order discounts, offering you cost-effective roll replacement and upgrades to effectively manage your operational costs.

Two Decades of Paper Roll Component Expertise: A Globally Trusted Supplier to the Paper Industry

With over two decades of profound experience in Paper Machine Roll manufacturing, we've become a trusted core roll supplier to numerous global paper enterprises. Our technical team provides expert roller maintenance consultancy and technical support for all paper machine types. Choosing us means selecting a long-term partner who understands your papermaking technology needs, dedicated to your continuous success and maximizing ROI on your roll assets.

Your Paper Machine Roll Supplier

Supplying All Types of Quality Paper Mill Rolls

"Optimize your paper production! Our Paper Machine Rolls, paper mill rollers, and various paper industry roll components are precision-engineered for the pulp and paper sector, serving as critical equipment parts for achieving high-efficiency manufacturing and superior paper quality. These industrial rollers are distinguished by their exceptional durability, outstanding reliability, and peak operational performance, ensuring stable operation and efficient functioning. Choose our high-performance roller solutions to significantly boost production efficiency, effectively reduce operational costs, and enhance your competitiveness in the paper market."

The latest industry dynamic content

News

12-22 · 2025

12-22 · 2025

The Heart of the Press: W

Explore the benefits of Granite Stone Roller Paper Machine Rolls Stone Roller for Paper Mill. Learn about durability, maintenance, and production effi...

Details 12-22 · 2025

12-22 · 2025

The Ultimate Guide to the

Explore the benefits of the Granite Press Roller for Paper Machine - High Hardness. Learn about its durability, precision, and impact on paper quality...

Details 12-21 · 2025

12-21 · 2025

The Ultimate Guide to Cho

Discover how to select top paper mill rolls manufacturers to boost efficiency. Learn about roll types, materials, and maintenance for optimal production....

Details 12-21 · 2025

12-21 · 2025

The Essential Guide to Se

Looking for a paper machine roller manufacturer? Learn how to choose the right partner to optimize your mill‘s efficiency and product quality....

DetailsGet quick answers to the most common questions buyers ask before ordering paper machine rolls.

Paper Roll Solutions FAQ

Every roll blank is dynamically balanced twice—before coating and after precision grinding. We use imported testing rigs to keep TIR within ±0.002 mm, so your paper web runs stable at high speed.

Yes. We formulate PU, rubber, granite or ceramic coverings in-house. Share your basis weight, line pressure and target finish, and our engineers deliver a matching Shore hardness and surface profile.

Standard refurbishment ships within 15–20 days after inspection. New roll manufacturing takes 30–45 days depending on shell diameter. We keep spare cores in stock to shorten urgent turnarounds.

Our field team can align rolls, calibrate crown profiles and assist with start-up worldwide. Remote diagnostics and vibration reports are also available to keep your mill running without surprises.

We manufacture new shells from forged alloy steel, stainless steel, carbon fiber composites and seamless cast iron depending on press position. Our vertical lathes handle up to 1,600 mm diameter and 12 m length with one-piece machining to protect shell integrity.

Each paper mill roll ships with ISO 9001 traceability, ultrasonic wall-thickness charts, hardness mapping, dynamic balancing curves and surface roughness records (Ra ≤ 0.2 µm when required). Third-party SGS or BV witnessing is available for OEM audits.

Yes. Our R&D team runs FEA to redesign shell thickness, crown curve and venting for higher line pressure. We also recommend PU or composite covers matched to water removal targets so you can increase production without crushing the sheet.

We keep semi-finished roll blanks and finished press rolls in consignment for strategic customers. If your line trips, we can ship a balanced spare within 72 hours and dispatch technicians to supervise swap-outs, minimizing paper machine downtime.