Products Description

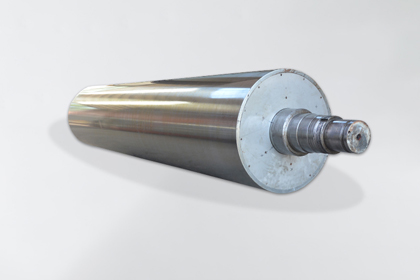

A chrome-plated roller is a roller with a surface coated with a layer of chromium metal. It is widely used in various industries.

Characteristics of Chrome-Plated Rollers:

High Hardness and Wear Resistance: The chromium layer possesses exceptional hardness, enabling it to resist wear, scratches, and impacts, thereby extending the roller's service life.

Excellent Corrosion Resistance: Chromium is a chemically stable metal, resistant to corrosion from various chemicals, making it suitable for use in corrosive environments.

Superior Surface Finish: Chrome plating can achieve a high surface finish, contributing to improved product quality and production efficiency.

Ease of Cleaning: The smooth chrome-plated surface prevents the adhesion of dirt and debris, facilitating easy cleaning and maintenance.

Good Thermal and Electrical Conductivity: Chromium exhibits good thermal and electrical conductivity, making it suitable for applications requiring heat transfer or electrical conductivity.

Applications of Chrome-Plated Rollers:

Chrome-plated rollers find extensive use in the following industries:

Printing Industry: Used in printing presses, offset machines, and other equipment to ensure print quality and efficiency.

Paper Industry: Employed in paper machines, calender rolls, and other equipment to enhance paper smoothness and gloss.

Plastic Film Industry: Utilized in film production lines to improve film thickness uniformity and surface quality.

Textile Industry: Used in printing and dyeing machines, stenters, and other equipment to enhance fabric dyeing quality and appearance.

Steel Industry: Employed in rolling mills, annealing furnaces, and other equipment to improve the surface quality and properties of steel.

Conclusion:

Chrome-plated rollers play a crucial role in various industries due to their outstanding properties. Their high hardness, wear resistance, corrosion resistance, and superior surface finish make them the preferred choice for numerous applications.

Tags: