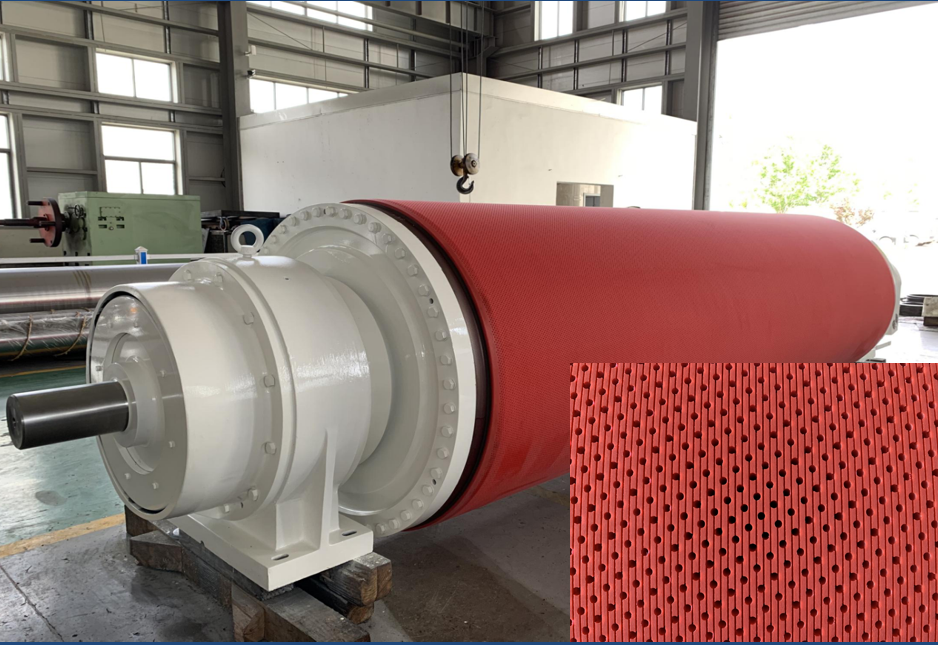

Products Description

The polyurethane surface is designed as a groove + blind hole pressing roller, which produces a lot of water throwing in the pressing zone, greatly improves the dewatering ability of the pressing zone, and reduces the dependence on the dehydration of the paper machine felt.

Polyurethane Cover Press Rolll Advantage:

1. The wear resistance is 3 to 5 times than rubber cover; the grinding cycle is longer, the number of broken ends is reduced, and the start-up time is increased.

2. The reinforced composite base layer can withstand the high line pressure of 350KN/M, and can press out the moisture in the paper and felt to the maximum extent.

3. The blind hole + groove design on the roller surface can make the opening rate up to 40%, good resilience, and stable middle-high curve.

4. Short dewatering path in the nip, low water pressure, long service time of the felt, and high bulk of the paper. Under the same working conditions, the dryness of the press section can be increased by more than 2%.

5. It can save 10% of steam and increase the speed by 10%.

Tags: