In the demanding world of paper manufacturing, every component plays a critical role in maintaining productivity and quality. To be honest, few components are as fundamental to the smooth operation and overall output of a paper machine as its rolls. These cylindrical workhorses, found throughout the machine's various sections—from the forming and pressing sections to the dryer and calendar sections—bear immense loads, operate under harsh conditions, and are indispensable for dewatering, web transfer, pressing, and finishing. Choosing the right roll isn't just a matter of finding a replacement; it's a strategic decision directly impacting speed, quality, energy consumption, and ultimately, profitability. Maximizing efficiency in your production line absolutely hinges on making informed choices about these vital parts. Have you ever stopped to consider just how much a seemingly simple roll can influence your entire operation?

Understanding the Critical Role of Paper Machine Rolls in Production Line Efficiency

Delving into the core concept of "Maximizing Efficiency" within the context of a "Paper Machine Production Line" necessitates a deep appreciation for what paper machine rolls actually do. It's not an exaggeration to say they are the backbone of the process. In the forming section, rolls help drain water from the pulp slurry to form a wet web. The press section utilizes rolls under tremendous pressure to squeeze out more water, consolidate the web, and improve strength, a step absolutely critical for energy savings later in drying. Dryer section rolls support the sheet and facilitate heat transfer, while calendar rolls are used for smoothing and finishing the paper surface. Each of these stages requires rolls with specific properties—surface hardness, cover material, structural integrity, balance, and dimensional accuracy—to perform their function flawlessly. A roll that is worn, improperly specified, or poorly maintained can lead to uneven dewatering, poor pressing, sheet breaks, quality defects, increased energy consumption, and reduced speed, all of which directly erode efficiency. Interestingly enough, selecting the correct roll, perfectly matched to its specific task and the operating conditions, is a primary driver of high-speed, high-quality, and energy-efficient paper production.

The performance of a paper machine roll isn't just about its immediate function; it also impacts the longevity and performance of surrounding components and the entire machine. A roll with an incorrect cover material might cause excessive wear on felts or fabrics. An imbalanced roll can induce vibrations, leading to mechanical stress on bearings, frames, and other rolls, potentially causing premature failure and costly downtime. Moreover, the surface condition of a roll is paramount. Surface defects, wear, or improper crowning can result in non-uniform pressure profiles in the press section or uneven heat transfer in the dryer, directly affecting moisture profiles and paper quality. Frankly speaking, these seemingly small issues with a single roll can cascade into significant inefficiencies across the entire "Production Line". Therefore, understanding these critical roles is the first step in answering the question of "How to Choose the Best Paper Machine Roll" for achieving peak operational performance and "Maximizing Efficiency".

Key Factors in Choosing the Best Paper Machine Roll for Your Application

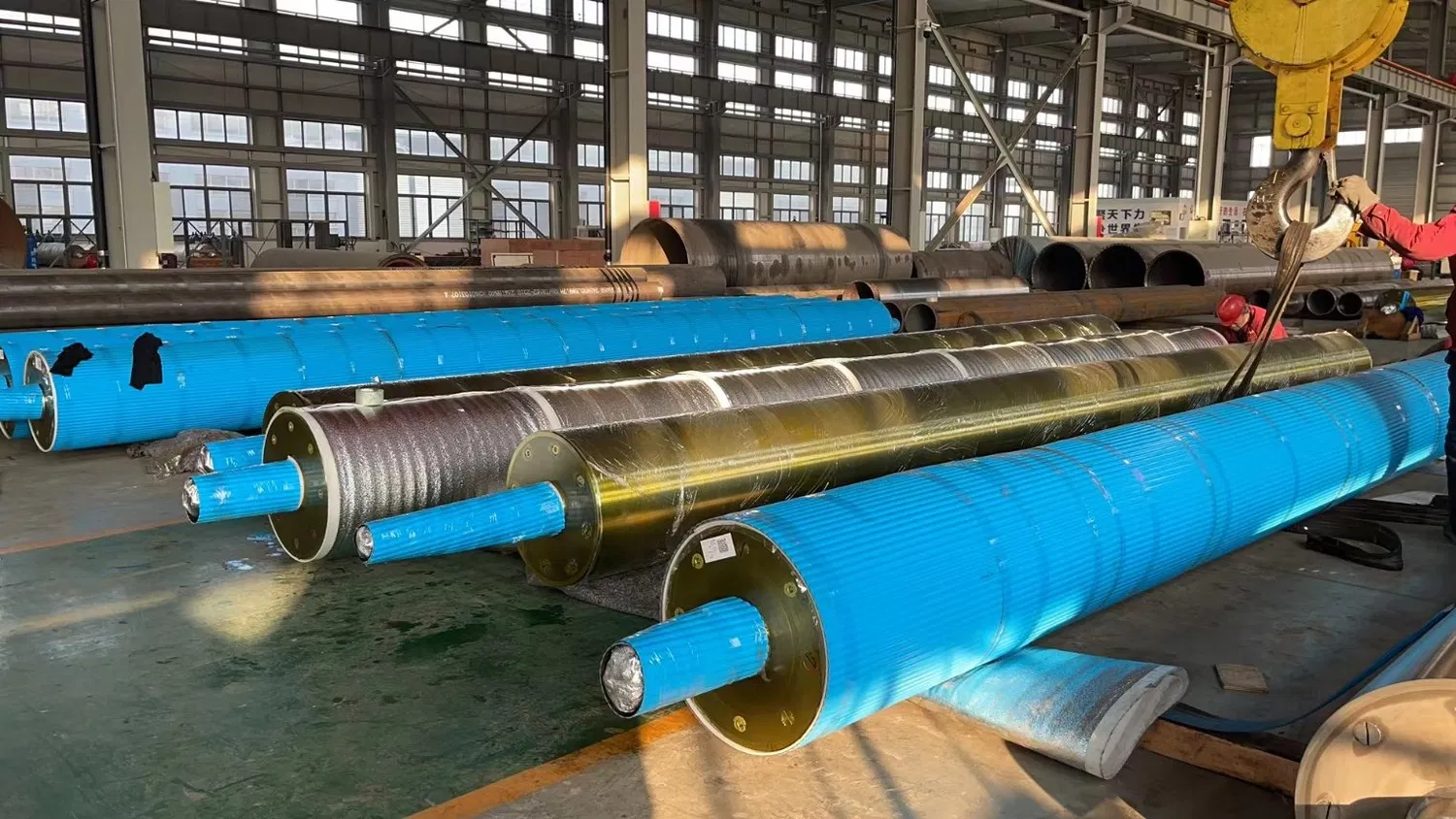

Moving towards "Choosing the Best Paper Machine Roll," we must dissect the key factors that differentiate one roll from another and determine its suitability for a specific position within the "Production Line." The material of the roll shell and its cover are arguably the most important considerations. Roll shells are typically made of steel, cast iron, or sometimes composites, chosen for their strength and rigidity. The cover, however, is where much of the specificity lies. Covers can be made of rubber, polyurethane, composite materials, or even ceramic, each offering different properties regarding hardness, wear resistance, chemical resistance, release properties (how well the sheet separates from the roll), and temperature resistance. The choice of cover depends heavily on the roll's function, the paper grade being produced, operating temperatures, chemical environment (e.g., pH of the pulp), and the desired pressure profile. For instance, a press roll might require a soft, compliant rubber cover to conform to the felt and paper web, while a dryer cylinder needs a material that facilitates efficient heat transfer and resists high temperatures.

Beyond materials, other specifications are equally crucial. The roll's diameter, face length, and crowning (a slight taper along the length to compensate for deflection under load) must be precisely matched to the machine's design and the desired process outcomes. A roll that is too small or too large, or one with incorrect crowning, cannot provide the necessary nip pressure profile or sheet support, leading to quality issues and inefficiency. Balancing is another non-negotiable factor, especially for high-speed machines. A poorly balanced roll creates vibrations that limit machine speed and cause structural damage. Roll bearing type and lubrication are also critical for smooth rotation and longevity, directly impacting uptime and maintenance requirements. Considering these diverse factors comprehensively is essential for "Choosing the Best" roll that will integrate seamlessly and contribute positively to "Maximizing Efficiency" on your "Production Line". It's a complex interplay of mechanical engineering, material science, and process understanding.

Matching Roll Specifications to Maximize Efficiency Gains

The true art of "Maximizing Efficiency" through roll selection lies in the meticulous process of "Matching Roll Specifications" to the unique demands of each position on the "Paper Machine" and the specific grades of paper being run. This isn't a one-size-fits-all scenario. A couch roll in the forming section requires excellent dewatering properties and resistance to wear from the wire fabric. A press roll needs to withstand high pressures and temperatures, resist chemicals, and often have specific surface patterns (like grooving or blind drilling) to manage water removal in the nip. Dryer rolls must handle high temperatures and sometimes steam pressure internally, while maintaining a smooth surface for sheet contact. Calendar rolls demand extremely smooth and hard surfaces for finish and caliper control. The speed of the machine also dictates requirements; higher speeds necessitate greater precision in balancing and materials that can withstand increased dynamic loads and wear rates.

Furthermore, the type of paper being produced significantly influences roll selection. Producing newsprint has different demands than producing fine paper or cardboard. Different pulp types, additives, and fillers can interact differently with roll cover materials. Understanding these interactions is paramount to selecting covers that offer optimal release properties, minimize sticking, and resist chemical degradation. For example, some fillers can be abrasive, requiring highly wear-resistant cover materials. Similarly, acidic or alkaline process water requires covers that can withstand these chemical environments without deteriorating. Successfully "Matching Roll Specifications" to these intricate process variables is where significant "Efficiency Gains" can be realized. It leads to fewer sheet breaks, lower energy consumption (especially in pressing), improved paper quality consistency, and reduced maintenance downtime – all direct contributors to a more efficient "Production Line". This is where technical expertise and experience truly come into play.

The Impact of Roll Maintenance and Technology on Long-Term Efficiency

While "Choosing the Best Paper Machine Roll" initially sets the stage for "Maximizing Efficiency," sustaining that efficiency over time is equally dependent on proper roll maintenance and leveraging advancements in roll technology. Even the perfectly specified roll will eventually wear down, its surface profile will change, and its balance may be affected. Regular inspection, cleaning, grinding, and re-covering are essential maintenance practices that restore a roll's performance characteristics and extend its operational life. Neglecting maintenance leads to a gradual decline in performance, manifesting as reduced dewatering, poorer quality, and increased energy use, ultimately eroding the initial efficiency gains. Proactive maintenance programs, including scheduled inspections and condition monitoring, are therefore vital for preventing unexpected failures and minimizing costly unscheduled downtime on the "Production Line".

Moreover, advancements in roll technology continually offer opportunities for further "Maximizing Efficiency". This includes new cover materials with enhanced wear resistance, improved release properties, or better thermal conductivity. Developments in roll shell construction, such as composite materials, can offer lighter weight and improved structural properties. Advanced balancing techniques and on-line vibration monitoring systems help ensure rolls run smoothly at higher speeds. Variable crown (VC) rolls, which can dynamically adjust their crowning profile, allow for optimization of nip pressure across the web width for different paper grades, leading to improved dewatering uniformity and paper quality. Investing in newer roll technologies, when justified by the specific application and potential efficiency returns, is a strategic way to stay competitive and achieve higher levels of performance on your "Paper Machine Production Line". I've found that companies that prioritize both diligent maintenance and technological upgrades often see the most significant long-term efficiency benefits.

Considering the long-term perspective, the total cost of ownership for a paper machine roll includes not just the initial purchase price, but also installation costs, energy consumption during operation, maintenance expenses (grinding, re-covering), and the cost of downtime due to roll-related issues. A cheaper roll might seem attractive upfront, but if it wears out quickly, requires frequent maintenance, or causes inefficiencies and downtime, its true cost can be far higher than a premium roll with superior performance and longevity. When thinking about "Choosing the Best" roll for "Maximizing Efficiency", it's crucial to evaluate these factors holistically. Sometimes, a higher initial investment in a technologically advanced or more durable roll yields substantial savings and performance improvements over its lifecycle. This underscores why the selection process is a strategic investment decision, not just a procurement task.

The Role of Supplier Expertise in Selecting the Best Rolls

Navigating the complexities of "Choosing the Best Paper Machine Roll" specifications to effectively achieve "Maximizing Efficiency" on your "Production Line" often requires deep expertise. This is where the role of a knowledgeable supplier becomes invaluable. A good supplier doesn't just sell rolls; they offer technical support, application knowledge, and the ability to recommend the most suitable roll type, material, and specifications based on your specific machine type, operating conditions, paper grades, and production goals. They can help you understand the trade-offs between different materials, explain the benefits of specific cover types or roll designs, and assist in troubleshooting performance issues. Leveraging this expertise can prevent costly mistakes in roll selection and ensure you are making the most informed decision for your specific needs.

Furthermore, suppliers often have insights into the latest technological advancements in roll design and materials, which can be critical for improving performance and efficiency. They can provide data on the expected lifespan and performance characteristics of different rolls under various conditions, helping you plan maintenance schedules and predict replacement needs. Partnering with a supplier who understands the intricacies of "Paper Machine Production Lines" and the impact of rolls on overall efficiency is a strategic move that can significantly contribute to "Maximizing Efficiency". They can be an extension of your technical team, providing specialized knowledge that is essential for optimizing your operations. Have you considered how collaborating closely with your roll supplier could streamline your selection process and enhance outcomes?

Our company understands the critical importance of selecting and maintaining the right paper machine rolls for achieving peak "Production Line" performance. We offer a range of high-quality rolls and related services designed to help you address the challenges discussed, ensuring you are "Choosing the Best" solutions for your specific needs and effectively "Maximizing Efficiency". Our expertise in material science, roll design, and paper machine operations allows us to provide tailored recommendations and support, helping you optimize water removal, reduce energy consumption, minimize sheet breaks, and improve paper quality. We believe that with the right partnership, selecting the best paper machine rolls becomes a powerful strategy for enhancing your bottom line and achieving sustainable operational excellence.

In conclusion, "Maximizing Efficiency: How to Choose the Best Paper Machine Roll for Your Production Line" is a topic of paramount importance for anyone involved in paper manufacturing. The selection process is multifaceted, requiring careful consideration of the roll's function, operating conditions, material properties, specifications like crowning and balancing, and the specific paper grades produced. Proper maintenance and the adoption of advanced roll technologies are also crucial for sustaining high levels of efficiency over time. By understanding the critical role each roll plays and making informed, strategic choices based on technical expertise and collaboration with knowledgeable partners, paper manufacturers can significantly enhance their production line's performance, reduce costs, and improve paper quality. It's a continuous effort, but one that yields substantial rewards in the pursuit of operational excellence.

For more detailed information, please visit our official website: paper machine roll