In the complex and demanding world of papermaking, machinery is the backbone of production. Among the most critical components are the paper machine rolls. These aren't just simple cylinders; they are precision-engineered elements designed to withstand extreme conditions – high temperatures, immense pressures, and continuous abrasion – all while performing highly specific tasks that are absolutely vital to the formation, dewatering, pressing, drying, and finishing of the paper web. Frankly speaking, without well-functioning rolls, producing paper of consistent quality at efficient speeds would be impossible. This guide aims to provide an essential overview, diving deep into what makes these rolls so important, exploring their different iterations, understanding their diverse functions across the machine, and crucially, offering practical insights into their maintenance – the often-underestimated key to longevity and performance. Have you ever stopped to consider just how many different rolls a modern paper machine utilizes, or the unique job each one performs?

Understanding the Various Types of Paper Machine Rolls

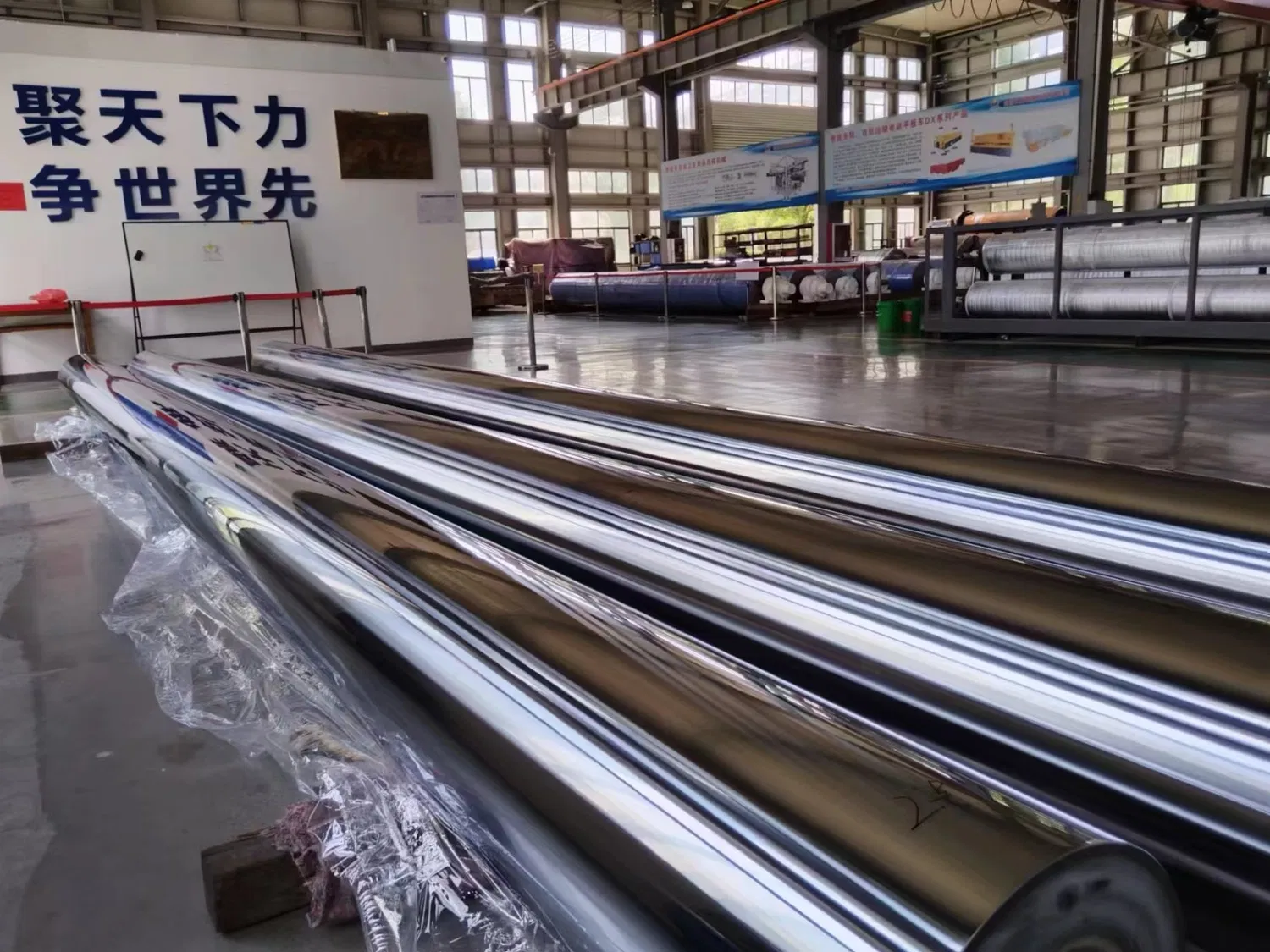

Delving into the specifics, the types of paper machine rolls are numerous and varied, each strategically placed and designed for a particular stage of the process. In the forming section, you encounter rolls like the breast roll, which supports the wire where the pulp slurry is initially deposited, and forming rolls, which help in initial dewatering. Moving to the press section, press rolls apply massive pressure to squeeze water out of the web; these can be plain press rolls, grooved rolls, blind-drilled rolls, or even sophisticated shoe press rolls, which use a long shoe instead of a round roll to extend the pressing nip, significantly improving dewatering efficiency. The dryer section relies heavily on dryer rolls, large heated cylinders that evaporate the remaining water, and felt rolls or guide rolls that manage the dryer fabrics. Further down the line, calender rolls iron the paper surface for smoothness and gloss, and reel spools build the finished paper into large rolls. Interestingly enough, the material composition and surface coating of these rolls vary significantly depending on their location and function, utilizing steel, cast iron, granite (historically), rubber, polyurethane, and specialized composite covers designed for specific properties like release, wear resistance, or nip uniformity. Identifying the correct type for a specific application is paramount to machine efficiency and product quality.

Common Roll Types by Machine Section

Let's break down some of these types by where you'd typically find them. In the wet end, besides the breast roll, there are couch rolls that assist in initial dewatering from the forming fabric, and turning rolls that guide the fabric itself. The press section, arguably the most critical for water removal, features rolls designed to create intense, uniform pressure. Plain press rolls are simple, solid or bored rolls. Grooved rolls have circumferential grooves to accept pressed water. Blind-drilled rolls have drilled holes for the same purpose but offer more uniform pressure distribution. Suction rolls, used in both forming and press sections, have perforated shells and internal suction boxes to vacuum water away. Shoe press rolls, as mentioned, are a marvel of engineering, replacing the conventional roll-to-roll nip with a hydraulic shoe pressing against a large roll, creating a much longer dwell time under pressure. In my experience, the transition to shoe presses was a game-changer for mill throughput and energy efficiency. The diversity reflects centuries of innovation aimed solely at improving the papermaking process.

Exploring the Essential Functions of Paper Machine Rolls

Beyond just existing within the machine, each paper machine roll performs a vital function, contributing directly to the transformation of a liquid pulp slurry into a finished paper sheet. The forming section rolls primarily serve to support the forming fabric and initiate the dewatering process, creating the very foundation of the paper web. As the web moves into the press section, the functions shift dramatically. Here, the rolls apply mechanical pressure – immense pressure, I should add – to squeeze out water that couldn't be removed by vacuum or gravity alone. This mechanical dewatering is incredibly energy-efficient compared to thermal drying, making the press section's function one of the most economically important. Press rolls compact the sheet, improving its density and strength, and can also influence surface properties depending on their design and covering. The dryer section rolls are tasked with supporting and guiding the paper web and dryer felts as heat is applied, facilitating the evaporation of the remaining moisture. Their smooth, heated surfaces ensure efficient heat transfer without marking or damaging the paper. Further downstream, calender rolls iron and smooth the paper surface, impacting caliper, gloss, and printability – crucial functions for the final product's appearance and feel. Each roll's function is interconnected, a chain of operations where the failure or inefficiency of one link impacts the entire process.

Key Functional Roles in Papermaking

To be honest, thinking about the paper machine as a giant, interconnected system of rolls helps grasp their functional significance. The guide rolls, found throughout the machine, ensure the proper tracking and tension of the forming fabrics, press felts, and dryer fabrics, which are essential for conveying the web smoothly and consistently. Spreader rolls are designed to eliminate wrinkles and creases in the web or fabrics. Size press rolls apply surface treatments like starch for strength or pigment for printability. Coater rolls apply coating layers to the paper surface. Reel spools aren't just taking up paper; they must build a consistent, tightly wound reel, requiring precise tension control. Every curve, every contact point, every pressure application is orchestrated by a specific type of roll performing a specific function. Consider the complex hydraulic loading systems on modern press rolls – they aren't just squeezing randomly; they are applying pressure profiles tailored to optimize dewatering and uniformity across the web width. This level of functional specialization is what makes the study of paper machine rolls so fascinating and critical for anyone involved in the industry. Why is this detailed understanding of function so important? Because it directly impacts maintenance strategy and troubleshooting.

Implementing Effective Maintenance Tips for Paper Machine Rolls

Now, onto the truly essential part – maintenance. Regardless of their type or function, paper machine rolls are subjected to incredibly harsh operating environments. High speeds, heavy loads, corrosive chemicals, and elevated temperatures all take their toll. Without proper maintenance, rolls will inevitably wear out, leading to decreased efficiency, poor paper quality, increased energy consumption, and eventually, costly downtime. Effective maintenance isn't just reactive repair; it's a proactive strategy. It begins with regular, thorough inspection. Visual checks for cracks, wear patterns, or cover damage are fundamental. Monitoring bearing temperatures and vibration levels can provide early warnings of impending failure. Lubrication is non-negotiable – ensuring bearings are properly greased or oiled according to manufacturer specifications prevents premature wear. Cleaning is also vital, particularly in the wet and press sections where pulp and additives can build up, affecting roll performance and potentially causing damage. Many experts agree that a robust preventative maintenance schedule, tailored to the specific types of rolls and their operating conditions, is the single most effective way to extend roll life and ensure reliable machine operation. Have you implemented a detailed inspection checklist for every roll type in your mill?

Practical Steps for Proactive Roll Care

Let's get practical with some concrete maintenance tips. Beyond routine inspection and lubrication, pay close attention to roll cover condition. Covers, whether rubber, polyurethane, or composite, are the working surface of many rolls. They are susceptible to wear, hardening, softening, cracking, and delamination. Regular grinding or resurfacing of roll covers is often necessary to restore the correct profile and surface properties, ensuring uniform nip pressure and optimal dewatering or finishing. This is a crucial step for maintaining paper quality and machine efficiency. Alignment is another critical factor; misaligned rolls cause uneven wear, vibration, and can lead to sheet breaks. Checking and correcting roll alignment should be part of the maintenance routine. For heated rolls, like those in the dryer section, monitoring internal steam or oil systems is essential for efficient heat transfer and preventing corrosion. It's worth noting that specialized tools and techniques are often required for accurate inspection and maintenance of paper machine rolls, such as non-destructive testing (NDT) methods for detecting internal flaws in roll shells or specialized alignment equipment. Proper documentation of maintenance activities, including inspection findings, repairs, and resurfacing history, provides valuable data for predicting maintenance needs and optimizing roll performance over time.

Addressing Common Issues Through Targeted Maintenance

Specific problems often arise with paper machine rolls, and targeted maintenance is key to addressing them. Wear is perhaps the most common issue, whether it's abrasive wear on covers from the paper web or fabrics, or wear on bearing journals. Regular monitoring allows for timely resurfacing or replacement before wear impacts performance or causes catastrophic failure. Corrosion, particularly in areas exposed to process water or chemicals, can degrade roll surfaces and shells; protective coatings and diligent cleaning help mitigate this. Cracking, especially in roll shells or journals, is a severe issue that often requires the roll to be removed for repair or replacement; NDT methods are invaluable for early detection. Bearing failure is another major concern, typically caused by inadequate lubrication, contamination, or excessive load; consistent lubrication schedules and vibration monitoring are the best defense. Roll deflection under load can impact nip uniformity and thus paper quality; while roll design plays a major role, ensuring bearings and loading systems are functioning correctly is part of maintenance. Frankly speaking, ignoring minor issues almost always leads to major, expensive problems down the line. Investing in proper maintenance is not an expense; it's a critical investment in asset longevity and operational stability.

The Importance of Roll Covering in Performance and Maintenance

While the roll shell provides structural integrity, it's often the roll covering that dictates the roll's interaction with the paper web and fabrics, profoundly influencing both function and the need for maintenance. Different coverings – rubber, polyurethane, composite, ceramic – offer specific properties. Soft rubber covers conform to the sheet, improving nip uniformity and dewatering in press sections. Harder covers provide durability and specific surface characteristics for finishing or coating. Composite covers offer lightweight alternatives with excellent strength and chemical resistance. The choice of cover material is directly tied to the roll's function and the specific demands of that position in the machine. Maintenance of these covers involves not just grinding to maintain profile and surface roughness but also inspecting for signs of aging, chemical attack, or heat damage. Proper cover selection for the operating environment is itself a maintenance strategy, as the wrong cover will wear quickly or fail prematurely. I've found that working closely with roll manufacturers and cover suppliers to select the optimal material pays dividends in extended run times and reduced maintenance frequency. It's a complex interplay between the base roll, the cover, and the process conditions, and understanding this relationship is crucial for effective roll management.

Conclusion: Maximizing Paper Machine Roll Life and Performance

In conclusion, paper machine rolls are indispensable components in the intricate process of papermaking, each type serving distinct, critical functions from forming the initial web to finishing the final sheet. From breast rolls and press rolls to dryer cylinders and calender rolls, their diversity is matched only by their importance. Maintaining these rolls effectively is not merely an option; it's a necessity for ensuring high-quality paper production, maximizing machine uptime, and controlling operational costs. A comprehensive approach to maintenance, encompassing regular inspection, proper lubrication, timely cleaning, and proactive steps like cover resurfacing and alignment checks, is the cornerstone of reliable paper machine operation. By understanding the specific types and functions of the rolls in your machine and implementing a rigorous maintenance program tailored to their needs, you can significantly extend their lifespan and optimize overall mill performance. We understand the challenges involved in managing paper machine rolls. Our expertise spans the spectrum of roll manufacturing, repair, and specialized maintenance services designed to keep your operations running smoothly and efficiently, ensuring your rolls perform at their peak. Which aspect of paper machine roll maintenance do you find most challenging?

For more detailed information, please visit our official website: Paper machine rolls