Achieving peak performance in a paper machine is not merely a desirable outcome; it's the lifeblood of profitability and consistent quality in the demanding world of paper production. At the very heart of this complex machinery lie the rolls – critical components that guide, press, dry, and finish the paper web. Their condition directly dictates everything from sheet quality and machine speed to energy consumption and overall operational efficiency. Neglecting these vital parts is, frankly speaking, an open invitation to costly downtime, diminished product quality, and frustrating inefficiencies. This article delves deep into what it truly means to "Unlock Peak Performance" by focusing on the often-underestimated but absolutely "Essential Paper Machine Roll Maintenance Guide." It's not just about fixing things when they break; it's about a proactive, informed approach that keeps your machine running at its absolute best, day in and day out.

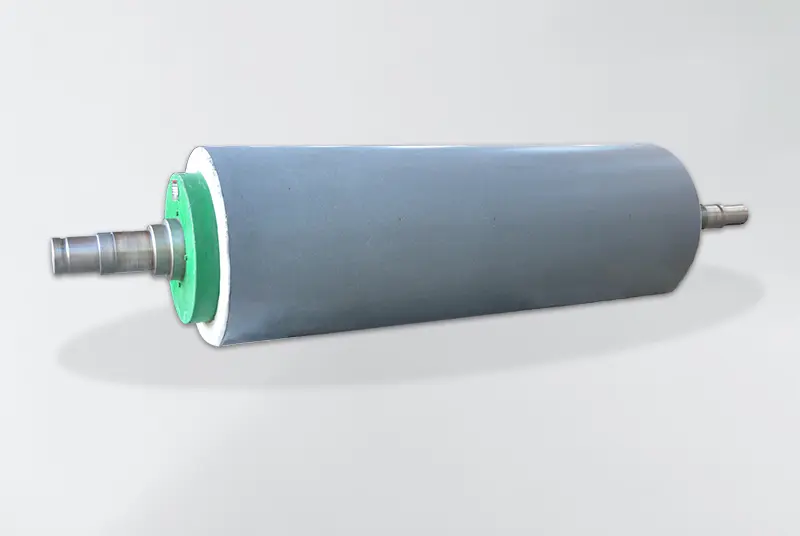

Understanding the significance of these rolls is the first step towards appreciating why a comprehensive maintenance strategy is indispensable. Think of a paper machine as a high-speed train; the rolls are its wheels, guiding it along the track. Any imperfection – a slight imbalance, a worn surface, a bearing issue – can cascade into major problems, affecting the entire train's stability and speed. In a paper machine context, this translates to sheet breaks, uneven moisture profiles, poor calendering results, and increased wear on other components. The sheer variety of rolls – forming rolls, press rolls, dryer rolls, calender rolls, reel spool bars, and more – each serving a unique function and facing distinct stresses, means that a generic maintenance approach simply won't cut it. A truly "Essential Paper Machine Roll Maintenance Guide" must address these nuances, providing targeted strategies that ensure every roll contributes positively to the machine's performance, rather than hindering it. This proactive mindset is the foundation upon which peak performance is built.

Understanding the Critical Role of Paper Machine Rolls for Peak Performance

The phrase "Unlock Peak Performance" inherently ties back to the foundational elements that make a paper machine operate effectively. And when we talk about foundations, paper machine rolls are undeniably central. Their precise geometry, surface condition, and internal workings are paramount. Consider the press section rolls, for example. They are responsible for mechanically removing water from the paper web. The pressure applied, the nip profile, and the surface characteristics of these rolls directly impact the sheet's dryness leaving the press section, a key factor in determining energy efficiency in the subsequent dryer section. A perfectly maintained press roll surface ensures uniform dewatering and prevents issues like picking or crushing. Conversely, a worn or improperly crowned roll can lead to uneven moisture, requiring more energy to dry and potentially causing quality defects. This single example highlights how the condition of just one type of roll can profoundly influence the machine's overall performance and energy footprint. It underscores the importance of truly understanding the function and requirements of each roll type within the context of achieving that elusive "peak performance."

Moreover, the dynamic environment in which these rolls operate adds layers of complexity to their maintenance. They are subjected to immense pressures, high temperatures (especially dryer cans), corrosive chemicals, abrasive fibers, and constant rotational stress. This harsh operating reality necessitates not just reactive repair but a predictive and preventative approach. Ignoring minor issues can quickly lead to catastrophic failures, resulting in unplanned downtime that can cost thousands, or even millions, of dollars per day depending on the machine's size and output. Therefore, integrating a robust roll inspection and monitoring program into your overall maintenance strategy isn't just a recommendation; it's an absolute necessity for sustaining "peak performance." Have you ever calculated the true cost of unexpected downtime caused by a roll failure? It's usually far higher than the investment in proper maintenance. This is why an "Essential Paper Machine Roll Maintenance Guide" focuses heavily on understanding the stresses rolls endure and predicting potential points of failure before they occur.

The 'Essential' Pillars of Effective Paper Machine Roll Maintenance

What makes a paper machine roll maintenance guide "essential"? It's the focus on core practices that form the bedrock of reliability and efficiency. These aren't optional steps; they are fundamental requirements for any mill aiming for consistent operation and "peak performance." Firstly, detailed inspection is paramount. This goes beyond a quick visual check and includes non-destructive testing methods like ultrasonic testing for internal flaws, thermography to detect bearing issues, and vibration analysis to identify imbalances or misalignment. Secondly, proper cleaning is critical. Residual fibers, chemicals, and deposits can alter roll surface properties, affect sheet release, and even lead to corrosion or wear. Effective cleaning procedures, tailored to the specific roll type and its operating environment, are vital. Thirdly, lubrication and bearing maintenance cannot be overlooked. Bearings are the support system for the rolls; their failure can cause significant damage to the roll itself and surrounding components. A rigorous lubrication schedule using the correct type and amount of lubricant is foundational, coupled with regular inspection and replacement of bearings as needed. These three pillars – detailed inspection, proper cleaning, and diligent bearing maintenance – form the absolute core of any effective "Essential Paper Machine Roll Maintenance Guide."

Beyond these basic pillars, an "essential" guide must also emphasize accurate roll handling and storage. Improper lifting or storage can cause roll damage before it even gets into the machine. Rolls are precision-engineered components; dropping one or storing it incorrectly can lead to permanent deformation or damage to journals and surfaces. Furthermore, maintaining accurate records of each roll's history – its installation date, running hours, maintenance performed, and any issues encountered – is incredibly valuable. This historical data allows for informed decision-making regarding maintenance schedules, predicting wear rates, and determining when a roll is approaching the end of its service life. Many experts agree that a well-maintained roll history database is one of the most underutilized tools in achieving "peak performance" through maintenance. It allows for a transition from calendar-based maintenance to condition-based maintenance, optimizing resources and minimizing unnecessary downtime. This systematic record-keeping is truly an "essential" element that elevates a basic checklist to a comprehensive guide.

Key Maintenance Practices for Different Paper Machine Rolls

While the foundational principles of maintenance apply broadly, an "Essential Paper Machine Roll Maintenance Guide" must differentiate practices based on roll type and function to truly "Unlock Peak Performance." Dryer cans, for example, require specific attention to internal cleanliness to ensure efficient heat transfer, as well as external surface inspection for wear or damage that could affect sheet contact and drying. Calender rolls, particularly those with specialized surfaces like chrome or soft covers, demand precise grinding and finishing to maintain the required nip profile and surface smoothness for achieving desired paper properties like gloss and caliper. A scratch or imperfection on a calender roll can leave a visible mark on the paper, impacting quality. Press rolls with rubber or composite covers require regular regrinding or recovering to maintain the correct crown profile and surface properties essential for dewatering efficiency and avoiding issues like vibration. The varying demands placed upon these different rolls mean that maintenance routines must be specifically tailored. A one-size-fits-all approach is likely to be ineffective and could even cause damage.

Consider suction rolls, vital for water removal in the forming and press sections. Their maintenance involves inspecting and cleaning internal drillings to ensure proper vacuum and drainage, checking bearing and seal integrity, and inspecting the shell for corrosion or cracking, especially around the drilled holes. These rolls are under constant load and vacuum, making structural integrity checks critical. Couch rolls, often the final roll in the forming section, also deal with significant water and fiber loads, requiring robust cleaning and inspection for wear and accumulation. Even seemingly simpler rolls like guide rolls or felt rolls require attention to bearing health and alignment to ensure smooth, consistent web travel and prevent flapping or wandering that can lead to breaks. Frankly speaking, every single roll on the machine, regardless of its apparent complexity, plays a part in the overall system. An "Essential Paper Machine Roll Maintenance Guide" acknowledges this interconnectedness and provides specific guidance for each major roll category, ensuring that no critical link in the chain to "peak performance" is overlooked due to generalized maintenance protocols.

Leveraging Technology and Expertise in Roll Maintenance Guide Implementation

Simply having a maintenance guide, even an "essential" one, is only part of the equation for achieving "peak performance." The effective implementation of that guide often relies heavily on leveraging modern technology and accessing specialized expertise. Predictive maintenance technologies, such as continuous vibration monitoring, online thermography, and acoustic analysis, can provide real-time insights into roll health, allowing for early detection of potential issues like bearing wear, imbalance, or structural fatigue. Integrating these technologies into your maintenance program allows for a shift from scheduled shutdowns based on time to condition-based interventions, optimizing uptime and reducing the risk of unexpected failures. Furthermore, advanced analytical tools can process data from these sensors, combined with historical maintenance records, to provide sophisticated diagnostics and prognostics, helping maintenance teams make informed decisions about when and how to service a roll. This level of technological integration is increasingly becoming an "essential" component of a modern maintenance strategy aimed at truly unlocking the full potential, or "peak performance," of a paper machine.

Access to specialized expertise is equally vital. While internal maintenance teams are crucial, certain roll maintenance tasks, such as high-precision grinding, specialized cover applications, dynamic balancing, and complex structural repairs, often require the skills, equipment, and facilities of external experts. Partnering with reputable roll service providers ensures that these critical tasks are performed to the highest standards, utilizing the latest techniques and materials. These partners can also offer valuable insights into best practices, troubleshoot persistent issues, and help develop customized maintenance plans based on your specific machine and operating conditions. Interestingly enough, many mills find that the investment in specialized external services for critical tasks ultimately reduces overall maintenance costs and improves reliability compared to attempting complex repairs internally without the necessary expertise or equipment. This blend of internal capabilities and external specialization, guided by an "Essential Paper Machine Roll Maintenance Guide" and empowered by technology, is a powerful combination for sustaining "peak performance." We, as a company, offer services and solutions precisely aimed at providing this blend of technological support and expert service for paper machine roll maintenance.

Implementing a Comprehensive Roll Maintenance Program for Sustained Performance

Transitioning from ad-hoc repairs or basic routines to a truly comprehensive paper machine roll maintenance program is fundamental to achieving sustained "peak performance." This isn't just about having a list of tasks; it's about building a culture of proactive care and continuous improvement. A comprehensive program starts with a detailed inventory of all paper machine rolls, including specifications, location, operating conditions, and maintenance history. This forms the baseline. Next, develop specific maintenance procedures and schedules for each roll type based on manufacturer recommendations, operating conditions, and historical data. These procedures should include detailed steps for inspection, cleaning, lubrication, and criteria for repair or replacement. Training maintenance personnel is also paramount; they need to understand the specific requirements of each roll, the proper techniques for inspection and maintenance, and the importance of accurate data recording. A well-trained team is far more likely to identify potential issues early and perform tasks correctly, directly contributing to machine reliability and helping to "Unlock Peak Performance."

Furthermore, integrating roll maintenance into the broader plant-wide asset management system is crucial. This allows for better planning and scheduling of maintenance activities, coordination with production schedules to minimize disruption, and analysis of maintenance costs and effectiveness. Regular reviews of the maintenance program are also "essential." Are the procedures effective? Is the scheduling optimal? Are there new technologies or techniques that could improve efficiency or reliability? Gathering feedback from maintenance staff and production operators, analyzing performance data (such as unplanned downtime related to rolls, sheet breaks, or quality issues), and continuously refining the program based on these insights ensures that the "Essential Paper Machine Roll Maintenance Guide" remains relevant and effective over time. This iterative process of planning, execution, monitoring, and refinement is what truly transforms maintenance from a necessary expense into a strategic tool for achieving and maintaining "peak performance" in paper production. Have you established clear key performance indicators (KPIs) specifically for your roll maintenance program?

Troubleshooting Common Roll Issues and Preventing Downtime Through the Guide

Even with the most "essential" maintenance guide in place, issues can sometimes arise. The key to minimizing their impact and preventing costly downtime is knowing how to effectively troubleshoot common paper machine roll problems, guided by your maintenance plan. Issues like roll vibration can stem from various causes: imbalance, misalignment, bearing damage, or even resonance with machine speed. Your guide should outline steps for diagnosing vibration sources, starting with simpler checks like cleaning and visual inspection, moving towards vibration analysis and potentially dynamic balancing. Surface wear or damage, such as grooving, pitting, or corrugation, might indicate issues with doctor blades, process chemicals, or even the paper furnish itself. The guide should provide protocols for inspecting surfaces, identifying the type of wear, and linking it back to potential causes in the process or upstream equipment. Identifying the root cause, rather than just fixing the symptom, is critical for preventing recurrence and maintaining "peak performance."

Other common problems include bearing overheating, which points directly to lubrication issues, improper installation, or internal damage; and roll cover failures, which can be caused by chemical attack, mechanical damage, or operating outside specified load or temperature limits. An "Essential Paper Machine Roll Maintenance Guide" should equip your team with checklists and diagnostic trees to systematically approach these issues. For instance, a guide for diagnosing bearing overheating would include checking lubrication levels and type, inspecting the bearing visually, using thermography, and potentially analyzing the lubricant for contamination. Preventing downtime isn't just about rapid repair; it's about anticipating these issues. Using the guide's recommended inspection frequencies and predictive technologies helps catch problems like bearing wear or cover degradation early, allowing for scheduled maintenance during planned outages rather than reacting to a sudden failure. This proactive troubleshooting approach, embedded within the maintenance guide, is paramount to ensuring the continuous operation and "peak performance" of your paper machine.

In conclusion, unlocking and sustaining peak performance in a paper machine hinges significantly on the meticulous care of its numerous rolls. An "Essential Paper Machine Roll Maintenance Guide" is far more than a simple checklist; it's a strategic framework encompassing detailed understanding of roll function, proactive inspection, precise maintenance practices tailored to different roll types, leverage of modern technology, and a commitment to continuous improvement. By adhering to such a guide, mills can mitigate the risks of costly downtime, improve product quality, optimize energy consumption, and extend the lifespan of critical assets. Implementing a comprehensive program requires commitment, training, and potentially, partnership with experts offering specialized services and solutions. It’s an investment that pays dividends in reliability, efficiency, and ultimately, the ability to consistently achieve that desired state of "peak performance."

For more detailed information, please visit our official website: Paper Machine Roll Maintenance