When it comes to the intricate world of paper manufacturing, few components are as critical, or perhaps as often overlooked in their full complexity, as paper machine rolls. These workhorses are absolutely essential, serving various vital functions from forming the paper sheet to pressing out water and smoothing the surface. Their design, the materials used, and how they are cared for directly impact everything from product quality and machine efficiency to overall operational costs. Frankly speaking, mastering the selection, implementing rigorous maintenance, and understanding how these factors influence performance is not just beneficial; it's non-negotiable for any mill striving for excellence in today's competitive market. This guide delves into these core aspects, offering a detailed look at how to make informed decisions that drive superior results on your paper machine.

Selecting the Right Paper Machine Rolls: A Foundation for Performance

Selecting the appropriate paper machine rolls is arguably the most foundational step influencing long-term performance and operational success. It's not a one-size-fits-all scenario; the specific function a roll performs within the machine dictates its design requirements, material composition, and surface properties. For instance, press rolls require surfaces that effectively dewater the sheet without damaging it, often utilizing sophisticated cover materials. Calender rolls, on the other hand, need precise finishes to impart the desired smoothness and gloss to the final paper product. Factors such as line load, operating temperature, speed, chemical environment, and the type of paper being produced all play significant roles in the selection process. Making the wrong choice here can lead to premature wear, suboptimal dewatering, poor sheet quality, and even catastrophic failures, severely hindering your machine's performance capabilities. It's worth noting that this selection process is highly technical and often requires close collaboration with experienced suppliers who understand the specific demands of your application and machine position.

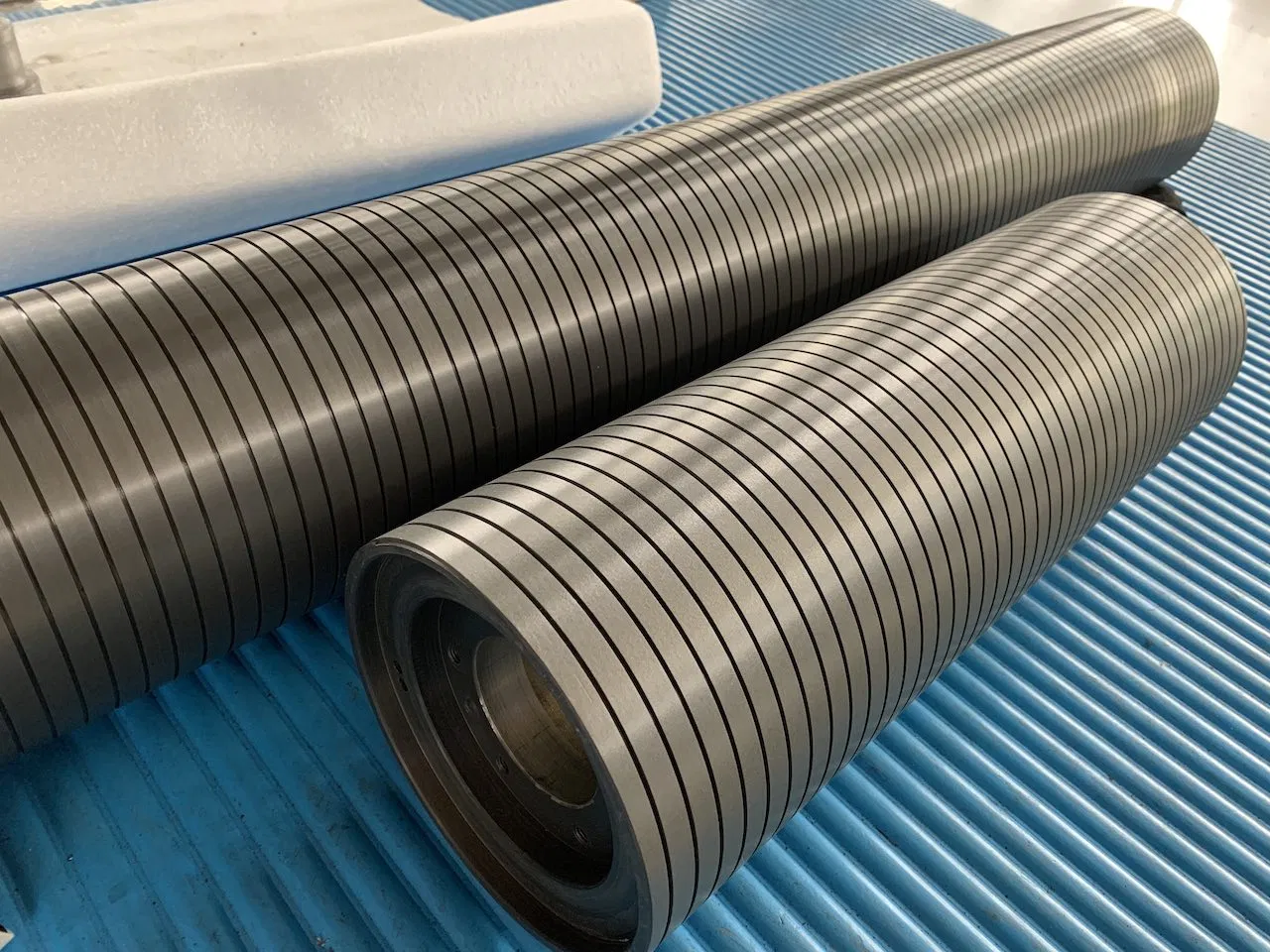

Beyond the primary functional requirements, considering the roll's core construction material, journal design, and bearing type is also paramount during selection. Steel cores are common, but variations in alloy and heat treatment affect strength and durability. The journals must be robust enough to handle immense loads while allowing smooth rotation. Bearings need to be selected based on speed, load, and environment, with lubrication systems designed for reliability. Furthermore, the choice of roll cover material – whether rubber, polymer, ceramic, or composite – is a critical decision that significantly impacts surface characteristics, wear resistance, release properties, and temperature tolerance. Each covering has unique advantages and limitations, making the selection process complex. Have you ever considered how the wrong cover material could compromise your paper's final surface finish or lead to excessive sticking?

Understanding the Impact of Roll Coverings on Selection & Performance

The selection of the roll covering is a cornerstone decision that dramatically influences both the initial roll selection and its subsequent performance throughout its lifespan. These coverings aren't just protective layers; they are engineered surfaces designed to perform specific tasks under extreme conditions. For instance, press section roll covers are engineered with precise hardness, grooving patterns, and surface textures to optimize water removal efficiency while minimizing sheet rewetting. Suction roll shells often feature drilled patterns covered with resilient materials to support the sheet and assist dewatering. In the calendar section, covers are chosen to achieve specific surface finishes, from high gloss to matte, and must withstand high temperatures and pressures without deforming or losing their properties. The chemical environment, such as the presence of sizing agents, fillers, or acidic conditions, also dictates the required chemical resistance of the cover material. A cover susceptible to chemical attack will degrade rapidly, leading to surface imperfections, reduced lifespan, and negatively impacting paper quality and machine uptime. Interestingly enough, advancements in polymer and composite technologies continue to expand the range of available covers, offering improved wear resistance, release properties, and dynamic performance characteristics.

The dynamic performance of a roll, which is intrinsically linked to its covering, involves factors like vibration dampening, nip uniformity, and energy consumption. A properly selected and applied cover can significantly reduce vibration, leading to smoother machine operation, less web breaks, and improved paper quality. Nip uniformity, critical in press and calender sections, is heavily influenced by the cover's deformation characteristics under load; achieving uniform pressure distribution is essential for consistent dewatering or finishing across the full width of the sheet. Furthermore, certain cover materials can reduce friction, potentially lowering energy consumption in driven rolls. The interaction between the cover, the paper sheet, and felts or fabrics is a complex tribological system. Selecting a cover that harmonizes with these other elements of the paper machine circuit is key to unlocking optimal performance. To be honest, overlooking the nuances of roll cover technology means leaving significant potential for performance gains on the table.

Essential Maintenance Practices for Paper Machine Rolls: Preserving Performance

Once the right rolls are selected and installed, rigorous and proactive maintenance becomes paramount to preserving their performance capabilities and extending their operational life. This isn't just about fixing things when they break; it's about preventing problems before they occur. Regular inspection is the backbone of effective roll maintenance. This includes visually checking for surface damage like cracks, cuts, or uneven wear, assessing the condition of journals and bearings, and monitoring lubrication systems. Techniques such as thermal imaging can detect overheating bearings, while vibration analysis can identify potential issues with balance or alignment long before they become critical. Documenting findings and tracking trends is crucial for predicting maintenance needs and optimizing scheduling. Many experts agree that a well-executed preventative maintenance program drastically reduces the likelihood of unplanned downtime, which can be incredibly costly in a paper mill environment.

Roll grinding and crowning are specific maintenance procedures absolutely essential for maintaining roll performance, particularly in sections like the press and calender. Over time, roll surfaces can wear unevenly or develop profiles that negatively affect nip uniformity. Grinding restores the desired surface finish and geometry, ensuring consistent pressure and optimal contact with the paper sheet and mating rolls or fabrics. Crowning, which involves grinding a specific, slightly curved profile onto the roll surface, compensates for the elastic deformation of the roll under load, helping to achieve a uniform nip pressure profile across the full width. The correct crown profile is calculated based on factors like roll material, cover type, diameter, and operating load. Incorrect crowning can lead to uneven moisture profiles or varying surface finish across the sheet, directly impacting product quality. Furthermore, regular cleaning of roll surfaces is vital to prevent build-up of fibers, fillers, or chemicals, which can cause surface imperfections, reduce dewatering efficiency, or lead to sticking. Implementing effective cleaning showers and doctor blades is a key aspect of routine maintenance.

Troubleshooting Common Roll Issues and Optimizing Performance

Even with the best selection and maintenance practices, issues can arise that impact paper machine roll performance. Being able to effectively troubleshoot these common problems is essential for minimizing downtime and restoring optimal operation quickly. Issues like uneven wear, barring (cyclical variations in surface wear), vibration, bearing failures, and cover delamination are relatively common. Uneven wear might point to issues with sheet profile, inconsistent nip pressure, or abrasive contaminants. Barring can be caused by resonance issues, improper grinding, or problems with bearings or drives. Vibration often indicates imbalance, misalignment, bearing problems, or foundation issues. Pinpointing the root cause requires a systematic approach, combining visual inspection, historical data, and diagnostic tools like vibration analysis or surface profile measurements. Understanding the potential causes associated with specific roll positions and symptoms is a critical skill for mill personnel.

Optimizing roll performance isn't just about fixing problems; it's also about continuously looking for ways to improve efficiency and lifespan. This involves analyzing performance data – such as dewatering rates, energy consumption, roll lifespan, and downtime related to rolls – to identify areas for improvement. Could a different roll cover material offer better wear resistance or release properties? Would optimizing grinding schedules reduce unplanned stops? Are there opportunities to implement advanced monitoring systems for predictive maintenance? Collaboration with roll suppliers and technology providers is invaluable here; they often have insights and solutions based on their experience across many mills. For example, advanced cover formulations or surface treatments might offer significant performance benefits in specific applications. Continuously evaluating and refining roll selection criteria and maintenance procedures based on operational feedback and technological advancements is key to achieving peak performance.

Leveraging Technology for Enhanced Roll Selection, Maintenance, and Performance

The paper industry, like many others, is increasingly leveraging technology to enhance the management and performance of critical assets like paper machine rolls. This impacts selection, maintenance, and ultimately, the roll's contribution to overall machine efficiency. During the selection phase, sophisticated simulation software can model the behavior of different roll designs and cover materials under anticipated operating conditions, helping engineers predict performance characteristics like nip profile and stress distribution. This allows for more informed decisions that go beyond traditional rule-of-thumb methods. For maintenance, the rise of Industry 4.0 technologies, such as the Industrial Internet of Things (IIoT), is transforming how rolls are monitored. Sensors can track vibration, temperature, and acoustic emissions in real-time, transmitting data for analysis. Predictive maintenance platforms use this data, often combined with machine learning algorithms, to anticipate potential failures or performance degradation before they become apparent through traditional inspection methods.

These technological advancements don't just improve maintenance; they directly contribute to enhanced performance. By predicting potential issues like bearing failure or uneven wear, mills can schedule maintenance proactively during planned shutdowns, preventing costly unscheduled stops and minimizing production losses. Continuous monitoring also allows for fine-tuning operational parameters based on real-time roll performance data. For instance, optimizing cleaning shower settings based on surface cleanliness monitoring or adjusting crowning strategies based on measured nip profiles. Furthermore, advancements in robotics and automation are making tasks like roll handling, grinding, and even some levels of in-situ inspection more efficient and safer. Adopting these technologies represents a significant investment, to be sure, but the potential returns in terms of increased uptime, reduced maintenance costs, improved paper quality, and extended roll life make them increasingly compelling for mills serious about optimizing their operations. It's fascinating to see how data and automation are reshaping what's possible in roll management.

Partnering for Optimal Paper Machine Roll Performance

Achieving truly optimal performance from your paper machine rolls often extends beyond internal capabilities and requires strategic partnerships. Collaborating closely with reputable roll manufacturers and service providers is invaluable across all stages: selection, maintenance, and performance optimization. During selection, their deep expertise in materials science, roll design, and specific machine positions can guide you towards the most suitable solutions for your unique operating conditions and production goals. They can help analyze your requirements, propose appropriate designs and cover materials, and even provide performance guarantees based on their experience. This partnership helps mitigate the risks associated with selecting complex and expensive components like rolls.

For maintenance, external partners can offer specialized services such as precision grinding, dynamic balancing, non-destructive testing, and bearing replacement that may require equipment or expertise not available in-house. They can also provide valuable training for your maintenance personnel on proper roll handling, inspection techniques, and basic troubleshooting. Furthermore, these partners are often at the forefront of developing new roll technologies, cover materials, and maintenance techniques. By maintaining open lines of communication and leveraging their knowledge, mills can stay ahead of the curve, implement best practices, and unlock new levels of performance. In my experience, the mills that consistently achieve high levels of efficiency and product quality are those that view their roll suppliers not just as vendors, but as true partners invested in their success. Our company, for instance, specializes in providing solutions and expertise throughout the entire lifecycle of paper machine rolls, from initial selection guidance to advanced maintenance services, aimed at helping mills maximize their operational efficiency and output quality.

Conclusion: Mastering Selection, Maintenance, and Performance

In conclusion, the journey towards optimizing paper machine performance is inextricably linked to the effective management of its rolls. As this comprehensive guide illustrates, making informed decisions during the selection phase, implementing rigorous and proactive maintenance practices, and continuously monitoring and troubleshooting roll performance are not isolated activities but interconnected pillars supporting overall machine efficiency and product quality. The right roll, with the appropriate cover and core design, chosen based on a thorough understanding of its function and operating environment, sets the stage. Maintaining that roll through regular inspection, timely grinding, and effective cleaning preserves its initial performance characteristics and extends its useful life. Ultimately, the synergy between selection and maintenance translates directly into improved dewatering, better sheet properties, reduced energy consumption, less downtime, and higher profitability. While challenging, mastering these aspects of paper machine roll management is a rewarding endeavor that yields significant returns. By focusing on these key areas – selection, maintenance, and performance – mills can ensure their rolls remain reliable, efficient, and contributors to sustained success in paper production.

For more detailed information, please visit our official website: Paper Machine Rolls