When it comes to the heart of paper production, the performance of a paper machine is undeniably tied to the quality and suitability of its components. Among the most critical are the paper machine rolls. These aren't just cylindrical pieces of metal or composite; they are precision-engineered elements that handle enormous loads, high speeds, and challenging environmental conditions, directly impacting the quality, efficiency, and profitability of the entire papermaking process. **Selecting the perfect paper machine roll** isn't a trivial decision; it requires a deep understanding of the machine's specific needs, the demands of the process, and the long-term operational goals. Frankly speaking, getting this selection right can mean the difference between smooth, high-quality production and frequent downtime, maintenance headaches, and inconsistent product. This article aims to break down the complexities involved, guiding you through the essential aspects you need to consider to make an informed choice. It’s about much more than just fitting a roll into a gap; it’s about optimizing performance and durability.

Understanding the Critical Role of Rolls in Paper Machine Performance

At its core, a paper machine is a series of complex sections – forming, press, dryer, calender, reel – each relying heavily on specialized rolls to perform its function. These rolls guide the web, remove water, consolidate the sheet, impart surface properties, and wind the finished product. Each position places unique demands on the roll regarding load, temperature, chemical exposure, and surface requirements. For instance, press rolls must withstand immense pressure to squeeze water out of the sheet, while dryer section rolls operate at high temperatures. Calender rolls need precise surface finishes to achieve desired smoothness and caliper. Interestingly enough, even a seemingly minor variation in a roll's surface, balance, or material can propagate through the machine, affecting everything downstream. This is why understanding the specific **role** each roll plays within the broader process is the absolute first step in **selecting the perfect paper machine roll**. Without this foundational knowledge, you're essentially making a blind choice, hoping for the best rather than planning for optimal performance. Have you ever considered just how much stress and environmental challenge these components endure day in and day out? It's quite remarkable, and appreciating this helps underscore the importance of thoughtful selection.

Key Technical Factors for Selecting the Perfect Paper Machine Roll

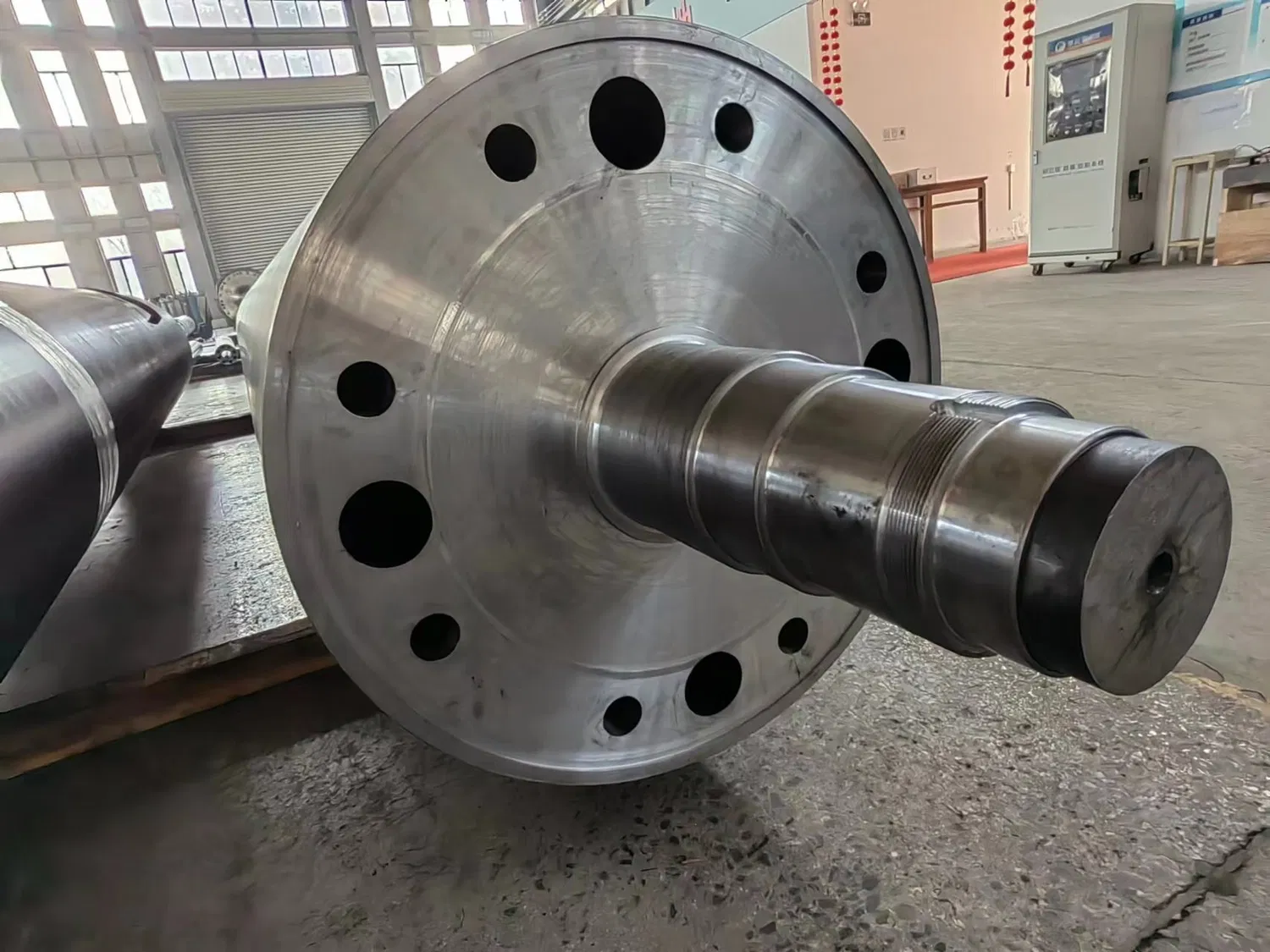

Diving into the technical details, several factors are paramount when **selecting the perfect paper machine roll**. The material of the roll shell and body is fundamental. Options range from various grades of cast iron and steel to sophisticated composites and granite. The choice depends heavily on the required strength, corrosion resistance, thermal conductivity, and weight limits for a given position. Furthermore, the roll's coating or covering is equally critical. Elastomeric covers, ceramic coatings, or specialized hard coatings provide specific surface properties like grip, release, abrasion resistance, or corrosion protection, tailored to the application. The roll's mechanical design – including its diameter, face length, and internal structure – determines its stiffness, critical speed, and load-bearing capacity. A roll that deflects too much under load can lead to uneven pressing or calendering, resulting in variations in sheet properties. Vibration is another enemy; proper balancing is essential to avoid operational issues and premature wear. All these technical specifications must align precisely with the operational parameters and quality targets of the paper machine section where the roll will be installed. It's a complex interplay of physics and engineering tailored to a demanding industrial environment.

Impact of Roll Surface and Coverings on Performance

When you're focused on **selecting the perfect paper machine roll**, paying close attention to the roll's surface is non-negotiable. The surface finish, geometry (like crowning or specialized grooving), and the type of covering applied dictate how the roll interacts with the paper web and other rolls. Elastomeric coverings, for example, offer compliance and nip control in press sections, with different polymer types providing varying degrees of hardness, temperature resistance, and wear characteristics. Hard coatings, such as ceramics or carbides, are often used in positions requiring extreme durability, abrasion resistance, or release properties, like in dryer or calender sections. The specific texture and porosity of these surfaces can influence water removal, sheet formation, and surface properties of the finished paper. Choosing the wrong surface can lead to problems like picking (where the paper sticks to the roll), uneven moisture profiles, or poor surface quality on the paper. To be honest, the advancements in roll cover technology have significantly expanded the possibilities for optimizing specific process steps, making the selection process even more nuanced but ultimately offering greater potential for performance improvement.

Considering Application-Specific Demands When Selecting Rolls

It's impossible to discuss **selecting the perfect paper machine roll** without deeply considering the specific section of the paper machine where it will function. A roll designed for the forming section, where the slurry first becomes a coherent web, faces vastly different challenges than a roll in the calender stack, which finishes the dried sheet. In the forming section, rolls might need specific dewatering features and surfaces that promote fiber retention while allowing water drainage. Press section rolls must handle high linear loads and often operate with complementary rolls (like granite or hard-covered rolls against soft-covered rolls) to achieve optimal dewatering and nip profiles. Dryer section rolls manage high temperatures and moisture, requiring materials and designs that handle thermal expansion and prevent corrosion. Calender rolls require exceptional surface finish and hardness for imparting smoothness and gloss. Reel spools need robustness to wind large, heavy rolls of finished paper accurately. Each application dictates unique requirements for materials, coatings, internal cooling/heating, and structural design. Ignoring these application-specific demands is perhaps the most common mistake made during the selection process, inevitably leading to suboptimal performance and potential operational issues down the line. What are the most critical performance indicators for *your* specific paper machine section?

Evaluating Supplier Expertise and Manufacturing Quality in Roll Selection

Let's be realistic: even armed with extensive knowledge about your process and the technical requirements, **selecting the perfect paper machine roll** is often best done in collaboration with a knowledgeable supplier. The manufacturing of paper machine rolls is a highly specialized field requiring significant expertise in metallurgy, precision machining, surface engineering, and balancing. A reputable supplier brings not only manufacturing capability but also a wealth of experience from various paper mills and applications. They can offer insights into the performance of different materials and coatings under specific operating conditions, help troubleshoot potential issues, and recommend designs optimized for longevity and performance. Assessing a supplier involves looking at their track record, their quality control processes, their engineering support capabilities, and their understanding of your specific mill environment and goals. Do they have experience with your type of paper product or your specific machine model? Do they offer ongoing support and maintenance services? These factors are just as crucial as the technical specifications of the roll itself because the supplier becomes a partner in ensuring the roll performs optimally over its lifespan. I've found that working closely with a trusted supplier who truly understands the nuances of papermaking makes the selection process significantly more effective and less prone to costly errors.

Long-Term Considerations: Maintenance, Service Life, and Total Cost of Ownership

Beyond the initial purchase price and technical specifications, **selecting the perfect paper machine roll** necessitates a look at the long-term implications. Maintenance requirements, expected service life, and the total cost of ownership (TCO) are critical factors. Some roll materials or coatings might offer exceptional initial performance but require frequent regrinding, recovering, or specialized maintenance, driving up operational costs. Others might have a higher upfront cost but offer significantly longer service intervals and greater durability, leading to a lower TCO over the roll's life. Energy consumption can also be influenced by roll selection; for example, rolls that facilitate more efficient dewatering in the press section can reduce the energy needed for drying. Ease of maintenance, such as accessible bearing lubrication points or robust seals, contributes to reduced downtime and labor costs. When evaluating options, ask prospective suppliers about the expected maintenance schedule, typical service life under your operating conditions, and the cost of refurbishment or recovering. A roll that seems perfect on paper based on initial performance might be prohibitively expensive in the long run due to high maintenance demands or short service life. Thinking about the lifecycle costs is essential for making a truly sound investment.

Navigating Common Challenges in Paper Machine Roll Selection

Let's face it, **selecting the perfect paper machine roll** isn't always straightforward. You might encounter challenges such as balancing performance requirements against budget constraints, dealing with legacy machine designs that limit options, or facing uncertain future production demands. Process variations, changes in furnish, or unexpected operational issues can impact roll performance in ways that weren't initially predicted. Furthermore, the sheer number of options available in terms of materials, coatings, and designs can be overwhelming. This is where expertise and collaboration become invaluable. A good starting point is a thorough assessment of the current roll's performance – what are its limitations? What problems is it causing? Uneven wear, vibration, sheet quality issues, or frequent maintenance needs all point towards specific areas for improvement. Based on this assessment, you can prioritize the most critical factors for the new roll. Is it maximum wear resistance? Improved dewatering? Better sheet finish? Clear goals help narrow down the options and focus the selection process. Don't be afraid to seek expert advice when facing complex trade-offs or unusual operating conditions. Many experts agree that leveraging supplier knowledge is key here.

Partnering for Success in Selecting Your Paper Machine Rolls

In the end, **selecting the perfect paper machine roll** is a strategic decision that impacts the heart of your operation. It requires a blend of understanding your specific process needs, evaluating technical specifications, considering long-term costs, and leveraging external expertise. Our company understands the complexities involved. We offer a comprehensive range of paper machine rolls, coverings, and services designed to meet the demanding requirements of modern papermaking. Our team works closely with mills to analyze their specific applications, troubleshoot issues with existing rolls, and recommend solutions optimized for performance, durability, and efficiency. Whether you need a specialized press roll cover to improve dewatering, a durable calender roll coating for superior finish, or expert advice on material selection for a challenging position, we have the knowledge and products to help you make the right choice. We believe that **selecting the perfect paper machine roll** is a collaborative process, and we are committed to being a trusted partner in helping you achieve your production goals. Investing time and resources in this critical selection process pays significant dividends in terms of uptime, product quality, and overall operational cost-effectiveness.

In summary, **selecting the perfect paper machine roll: what you need to know** involves understanding its specific function, evaluating technical parameters like material and surface treatment, considering application demands, assessing supplier capabilities, and looking at long-term costs and maintenance. It's a multi-faceted process that requires careful consideration and often benefits from expert guidance. By focusing on these key areas, you can make a selection that not only fits your machine but also enhances its performance and contributes positively to your bottom line. Taking the time to get this right is an investment in the future of your paper production.

For more detailed information, please visit our official website: Paper machine roll