In the intricate world of paper manufacturing, where massive machines churn out countless tons of paper every single day, every component plays a critical role. Among these components, the paper mill rolls stand out as arguably one of the most vital. These aren't just simple cylinders; they are precision-engineered workhorses subjected to immense pressure, high temperatures, abrasive pulps, and corrosive chemicals. Their performance directly dictates the efficiency and quality of the paper produced. To be honest, if these rolls aren't up to the task, the entire production line can grind to a halt. This brings us directly to the core concept of this article: the paramount importance of **durable paper mill rolls** and how their inherent toughness and resilience are key to **boosting productivity in paper production**. It’s a relationship that is perhaps underestimated by those outside the industry, but within the mill, the longevity and reliability of these rolls are top-of-mind concerns for operators and management alike. Achieving consistent, high-volume output simply isn't possible with components that wear out prematurely.

Understanding Durability in Paper Mill Rolls and Its Impact on Productivity

When we talk about **durable paper mill rolls**, what exactly does that mean in the context of **paper production**? It's not just about a roll lasting a long time before needing replacement. Durability in this application encompasses resistance to wear from the paper web itself and the various filler materials, resistance to corrosion from process water and chemicals, ability to withstand extreme mechanical pressures and thermal stresses, and maintaining dimensional stability under these harsh conditions. A truly durable roll minimises issues like uneven wear, surface pitting, cracking, or deformation. Why is this linked so directly to **boosting productivity**? Consider the alternative: a roll that wears quickly or fails unexpectedly. Each such incident requires the paper machine to be stopped – a costly and time-consuming process involving removal, repair or replacement, and then the complex procedure of bringing the machine back up to speed. Frankly speaking, every minute the machine is down translates directly into lost production volume. Therefore, the sheer ability of a roll to withstand the rigors of the paper mill environment over extended periods is the foundational element for maintaining high operational efficiency and, consequently, significantly boosting overall productivity.

Materials Science and Engineering for Enhanced Roll Durability

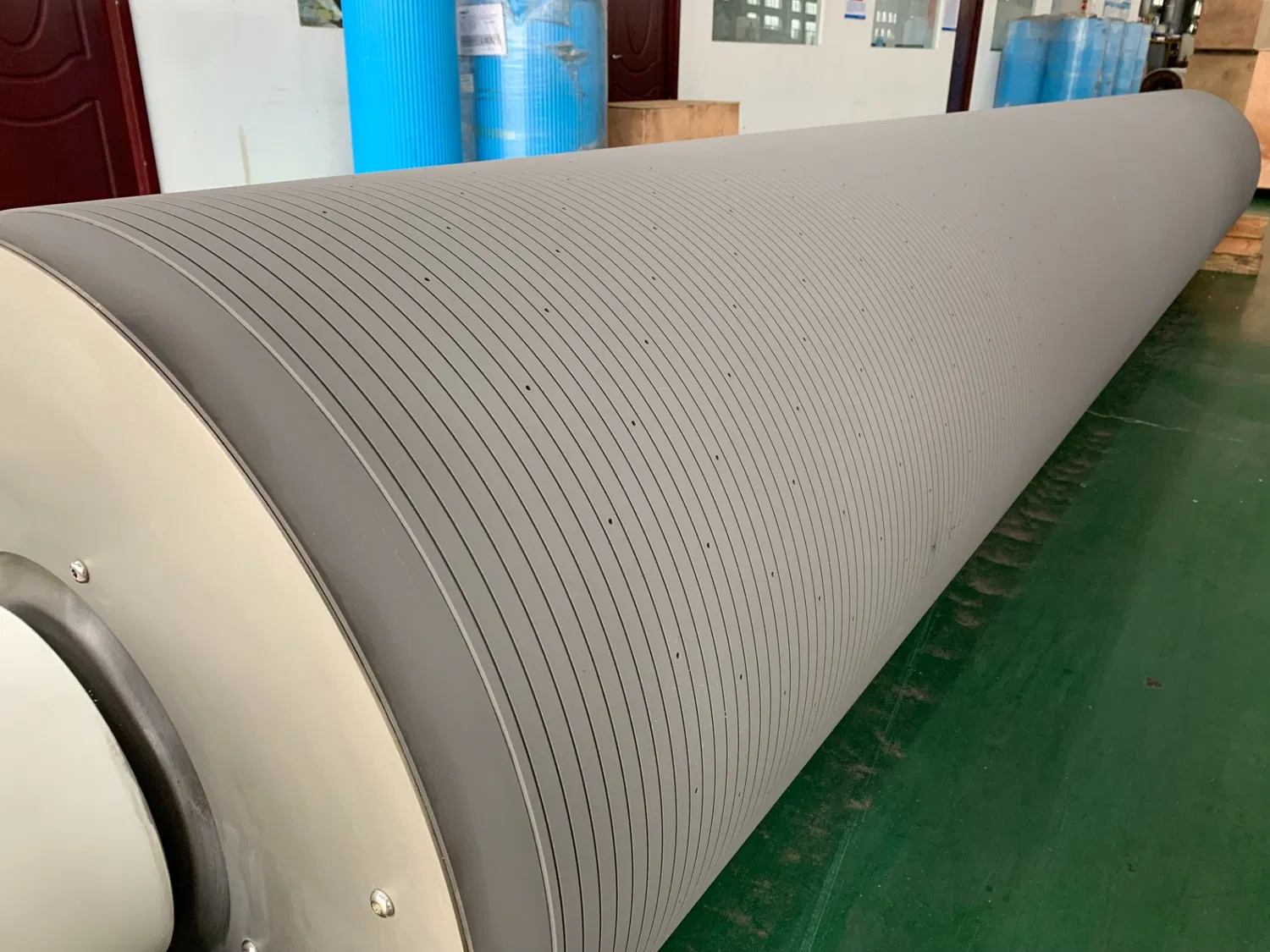

Achieving the necessary **durability** in **paper mill rolls** is a testament to advanced materials science and engineering. The choice of core material is crucial – often high-grade steel alloys that provide the structural integrity needed to handle immense loads. But the real magic often lies in the surface treatments and coatings. Depending on the specific function of the roll (e.g., press rolls, dryer rolls, calender rolls), different materials are applied or bonded to the core. These can include hard rubber or polymer covers for press sections to aid dewatering, specialized ceramic or metallic coatings for wear and corrosion resistance in dryer sections, or polished chilled cast iron or synthetic composites for the critical finishing touch in calender stacks. Interestingly enough, the development of new composite materials and application techniques, like thermal spray coatings or advanced polymer chemistries, has been a game-changer in extending roll life. These materials are designed not only to resist abrasion and chemical attack but also to maintain their surface properties, ensuring consistent interaction with the paper web. This focus on material **durability** at the design and manufacturing stage is a direct investment in future **productivity** gains for the paper mill operator.

The High Cost of Roll Downtime: A Direct Drag on Paper Production Productivity

Perhaps the most straightforward way to understand the link between **durable paper mill rolls** and **boosting productivity** is to look at the inverse relationship: the impact of roll failure or excessive wear. In a high-speed paper machine, unexpected downtime can cost thousands of dollars per hour, or even per minute, depending on the scale of the operation. When a roll needs replacement or repair prematurely due to lack of **durability**, the machine stops. This isn't just about swapping out a part. It involves complex rigging, potential cooling-down periods, maintenance crew time, troubleshooting, and then the delicate process of threading the paper web back through the machine and bringing it back up to operational speed and quality specifications. Each stop introduces risks, too – web breaks are more common during startups, which can lead to further delays. I've found that minimizing these unplanned stops is the single biggest factor in improving machine OEE (Overall Equipment Effectiveness). Therefore, investing in rolls designed for exceptional **durability** is not just a maintenance consideration; it's a strategic decision aimed squarely at reducing costly downtime and keeping the **paper production** line running consistently, thereby directly and powerfully **boosting productivity**.

Preventing Production Bottlenecks Through Roll Reliability

Beyond unexpected failures, rolls that lack sufficient **durability** can create production bottlenecks even when the machine isn't fully stopped. Uneven wear patterns on a press roll, for instance, can lead to inconsistent dewatering, impacting sheet moisture profiles and potentially limiting the speed of the machine in later sections like the dryers. A worn calender roll might fail to impart the desired finish or caliper uniformity, leading to off-spec product that must be reprocessed or scrapped, reducing salable output. These issues, while not always leading to a complete halt, subtly but significantly drag down overall **productivity**. A highly **durable** roll, on the other hand, maintains its optimal surface properties and dimensional accuracy for longer periods. This reliability ensures consistent performance throughout its service life, allowing the machine to operate at its designed speed and efficiency without compromises forced by component degradation. Many experts agree that reliable roll performance is fundamental to achieving and sustaining high levels of **paper production productivity**. Have you ever considered just how much minor component wear can cascade into major production headaches?

Durability's Role in Maintaining Consistent Paper Quality While Boosting Productivity

It's crucial to understand that **boosting productivity** in **paper production** isn't solely about speed and volume; it's also inextricably linked to maintaining consistent quality. Producing paper faster is pointless if a higher percentage of it is off-specification and must be discarded or downgraded. This is another area where **durable paper mill rolls** prove their value. Rolls with excellent **durability** maintain their surface finish and geometry over extended operational periods. For example, a durable couch roll or felt roll ensures smooth web transfer without damaging the fragile wet sheet. Press rolls with long-lasting covers provide uniform pressure distribution for consistent dewatering. Calender rolls that resist wear and thermal crown changes apply uniform pressure and temperature, resulting in consistent gloss, smoothness, and caliper. If rolls lack durability, surface imperfections can transfer to the paper web, leading to streaks, thin spots, or poor finish. Uneven pressure can cause variations in moisture content or thickness. These quality issues slow down the process (as operators try to compensate), increase waste, and necessitate rework – all of which are detrimental to **productivity**. Thus, the reliability afforded by durable rolls is essential not only for maximizing throughput but also for ensuring that throughput is of saleable quality, which is the true measure of effective **paper production productivity**.

Reducing Maintenance Frequency: A Key Productivity Gain from Durable Rolls

Beyond preventing catastrophic failures and maintaining quality, the inherent **durability** of high-quality **paper mill rolls** directly contributes to **boosting productivity** by significantly reducing the frequency of planned maintenance and roll changes. Rolls are subject to wear and eventually need to be resurfaced or replaced. However, rolls designed for exceptional **durability** can operate effectively for much longer cycles between maintenance shutdowns. This means fewer planned stops for roll grinding or cover replacement. While planned stops are less disruptive than unplanned ones, they still take the machine offline and consume valuable production time. By extending the time between these necessary maintenance interventions, durable rolls effectively increase the overall uptime of the paper machine over a given period, directly translating into higher annual **paper production** volume. Frankly speaking, optimizing maintenance schedules around components with long service lives is a fundamental strategy for maximizing operational efficiency. It frees up maintenance personnel for other tasks and keeps the focus firmly on production rather than constant component management.

The Long-Term Economic Advantage: How Durable Rolls Pay for Themselves in Paper Production

While **durable paper mill rolls** may sometimes carry a higher initial purchase price compared to less robust alternatives, their long-term economic benefits, particularly in terms of **boosting productivity**, make them a superior investment in **paper production**. The calculation is quite simple when you factor in the total cost of ownership. This includes not only the initial purchase but also the costs associated with installation, energy consumption (well-maintained rolls operate more efficiently), downtime due to failure or premature wear, maintenance labour and materials (including grinding and covering costs), and the financial impact of lost production and scrapped product. Rolls with superior **durability** drastically reduce these downstream costs. Fewer failures mean less unplanned downtime. Longer operational life means fewer planned roll changes. Consistent quality means less waste. Higher reliability allows the machine to run closer to its optimal speed and efficiency. When you add up the savings from reduced downtime, lower maintenance frequency, and improved quality over the lifespan of a highly durable roll, the initial investment premium is often dwarfed by the significant gains in operational efficiency and throughput. It’s a clear case where focusing on component **durability** directly leads to substantial and sustainable improvements in **paper production productivity** and profitability.

Considering Environmental Factors and Safety in Roll Durability

It's also worth noting that the **durability** of **paper mill rolls** has implications beyond just throughput and quality, extending to environmental impact and safety within **paper production**. Highly durable rolls reduce the need for frequent manufacturing, transportation, and installation of replacement rolls, inherently lowering the associated carbon footprint. Furthermore, minimizing roll failures and unplanned downtime reduces the waste generated from web breaks and off-spec paper. From a safety perspective, handling and changing large paper mill rolls is a complex and potentially hazardous operation. Reducing the frequency of these changeouts through the use of more **durable** components directly reduces the exposure of maintenance personnel to associated risks. Investing in rolls that are built to last isn't just smart business for **boosting productivity**; it aligns with increasingly important goals of sustainability and workplace safety. It’s a holistic approach where reliability benefits multiple facets of the paper mill operation. Have you considered how your roll procurement decisions impact the overall sustainability profile of your mill?

In conclusion, the link between **durable paper mill rolls** and **boosting productivity in paper production** is undeniable and multifaceted. These workhorse components are subjected to one of the most demanding industrial environments imaginable. Their ability to withstand intense pressure, heat, abrasion, and corrosion for extended periods directly translates into reduced downtime, consistent paper quality, lower maintenance costs, and ultimately, higher overall machine efficiency and throughput. Investing in rolls with superior **durability** is not merely a technical specification; it is a strategic decision that underpins the economic viability and operational excellence of a modern paper mill. By ensuring that these critical components are built to last and perform reliably, paper manufacturers can unlock significant gains in **productivity**, reduce waste, enhance safety, and improve their bottom line. Our company understands these challenges and specializes in providing paper mill rolls engineered for maximum **durability**, designed specifically to help you achieve these vital **productivity** goals in your **paper production** process.

For more detailed information, please visit our official website: Durable paper mill rolls