Frankly speaking, when you think about the intricate process of making paper, your mind might immediately conjure images of massive machines, pulp slurry, and vast reels of finished product. But often overlooked, yet absolutely fundamental to the entire operation, are the various paper machine rolls. These aren't just simple cylinders; they are highly engineered components, each performing a specific, critical task that collectively dictates the efficiency, quality, and overall performance of the paper manufacturing line. From the wet end all the way through to the dry end, the design, material, precision, and maintenance of these rolls are paramount. Optimizing the function of each roll is not merely about keeping the machine running; it's about enhancing dewatering, ensuring uniform pressing, achieving desired surface finishes, and controlling sheet properties, directly impacting production speed, energy consumption, raw material usage, and the final quality of the paper. Without these rolls functioning optimally, even the most advanced paper machine cannot achieve its full potential. It's a complex interplay where every roll contributes to the intricate dance of transforming pulp into the paper we use every day.

Engineering Rolls for Optimal Dewatering Performance

In the early stages of paper manufacturing, particularly in the press section, the primary goal is to remove as much water as possible from the nascent paper web before it enters the dryer section. This is where press rolls become indispensable components in optimizing performance. The efficiency of dewatering directly impacts the energy required for drying, which is the most energy-intensive part of the process. Well-designed press rolls achieve dewatering through a combination of pressure and nip geometry. The pressure applied in the nip (the point where two rolls come together) squeezes water out of the fiber web and into felts designed to absorb and transport the water away. The material and surface properties of these rolls are crucial; they must withstand immense pressure without deforming excessively, possess surfaces that don't damage the fragile web, and facilitate water removal. For instance, granite rolls were traditionally used, known for their hardness and resistance to wear, but modern technology often employs rolls with specialized covers made from polymers or composite materials. These covers can be designed with specific porosities or surface textures to improve water handling and reduce issues like picking (fibers sticking to the roll surface). The geometry of the nip, influenced by the rolls' shape, crown, and loading, is fine-tuned to maximize water extraction while maintaining sheet uniformity and strength. Optimizing these factors in the press section through advanced roll technology directly translates to significant energy savings and improved machine speed, boosting overall manufacturing performance.

Achieving Uniformity and Quality via Press and Size Rolls

Beyond mere dewatering, paper machine rolls in the press and subsequent sections play a vital role in consolidating the paper web, improving its strength, and preparing its surface for further processing or final use. Uniformity is key; any variation in pressure or surface contact across the width of the web can lead to uneven density, strength variations, or inconsistent surface properties in the final product. Press rolls, particularly in subsequent press nips, focus on improving fiber bonding and sheet structure after significant water has been removed. The uniform application of pressure is paramount here, often managed using controlled-nip rolls (like Sym-Sizer or similar concepts) that can adjust pressure profiles across the roll width to compensate for sheet variations or deflection. Following the press section, size press rolls apply starch or other surface treatments to the paper. These rolls require precise surface characteristics to ensure a uniform film of sizing agent is applied, which enhances strength, stiffness, and printability. The material and cover of size press rolls must resist chemical attack from the sizing solution and maintain dimensional stability at operating temperatures. A non-uniform application at the size press can lead to blotchy paper, uneven absorption of printing inks, and overall poor quality, directly hindering manufacturing performance in terms of yield and customer satisfaction. It's fascinating how the precision engineering of these rolls directly influences something as seemingly simple as how well ink sits on a page.

The Critical Role of Dryer and Calender Rolls

As the paper web leaves the press section, it still contains a significant amount of moisture, typically around 40-50%. Removing the remaining water falls to the dryer section, where large, heated dryer rolls come into play. These cast iron cylinders, often internally heated by steam, are designed to transfer heat efficiently to the paper web. While they might seem straightforward, their surface condition, alignment, and internal temperature control are critical for performance optimization. Uneven heating or surface defects can lead to non-uniform drying, causing issues like cockling or curling in the paper. Maintaining consistent contact between the paper web and the hot surface, often facilitated by dryer fabrics, is essential for effective heat transfer and moisture removal. After drying, the paper often passes through a calender stack, composed of a series of calender rolls. These rolls are perhaps the most significant contributors to optimizing the paper's final surface properties, including smoothness, gloss, and thickness (caliper). The nip pressure and temperature in the calender stack compact the paper and smooth its surface. Hard rolls, often made of chilled cast iron or composite materials, are used in conjunction with softer rolls (historically cotton or wool, now often polymer composites). The precise control of pressure, temperature, and speed in the calender stack, mediated by the properties of the rolls, determines the paper's finish. Achieving the desired level of smoothness and caliper uniformity across the full width of the reel is a direct measure of calender roll performance and is vital for downstream converting and printing processes. Have you ever felt the difference between a matte and a glossy paper? That difference is largely sculpted by the calender rolls.

Optimizing Roll Materials and Surface Technology

The fundamental properties of paper machine rolls—their hardness, chemical resistance, thermal stability, and surface energy—are determined by the materials they are made from and the coatings or covers applied to their surfaces. This material science aspect is a key area for optimizing performance. Traditional materials like granite and cast iron are still used, but advancements in polymer, ceramic, and composite technologies have revolutionized roll covers. These modern covers can be engineered with specific properties to address common issues that limit performance, such as wear, corrosion, sheet sticking, and bacterial growth. For example, press roll covers are designed to optimize dewatering and prolong felt life while resisting the harsh chemicals sometimes present in the pulp. Calender rolls might feature hard ceramic or composite covers that offer superior wear resistance and the ability to achieve high gloss levels. Chrome plating was once common for its hardness, but environmental concerns and the development of alternative coatings have led to new solutions. The surface texture of a roll can be manipulated through grinding, embossing, or specialized coatings to influence sheet release, nip friction, and liquid transfer (like in size presses). The choice of material and surface treatment is a complex decision based on the specific position of the roll in the machine, the type of paper being produced, and the desired performance outcome. In my experience, investing in the right roll cover technology can yield significant improvements in uptime, sheet quality, and operational efficiency.

The Impact of Precision Engineering and Maintenance

Even the most advanced roll material or cover will fail to deliver optimal performance if the roll itself is not manufactured and maintained with extreme precision. Paper machine rolls operate under demanding conditions – high speeds, heavy loads, high temperatures, and sometimes corrosive environments. Precision engineering ensures that rolls are perfectly cylindrical, balanced, and aligned within the machine frame. Any deviation in these parameters can lead to vibrations, uneven pressure distribution, uneven wear, and ultimately, compromised paper quality and potential machine damage. Roll balancing is critical, especially at high speeds, to prevent vibration that can mark the paper or cause mechanical stress. The crown (a slight taper or profile across the roll face) must be precisely calculated and ground to compensate for roll deflection under load, ensuring a uniform nip pressure across the entire width of the paper web. Regular inspection and maintenance are equally vital for sustained performance optimization. This includes monitoring roll surface condition for wear, damage, or accumulation of deposits, checking bearing health, and verifying alignment. Regrinding rolls to restore their precise profile and surface finish is a standard maintenance practice. Proactive maintenance, utilizing technologies like vibration analysis and thermal imaging, can identify potential issues before they lead to performance degradation or costly failures. Frankly speaking, ignoring roll maintenance is a surefire way to sabotage your paper manufacturing performance.

Integrating Control Systems for Dynamic Roll Optimization

Modern paper machines are equipped with sophisticated control systems that work in tandem with advanced roll technology to dynamically optimize performance. These systems utilize sensors to monitor critical parameters like nip pressure profiles, roll temperatures, web moisture content, and sheet caliper and smoothness. Based on this real-time data, the control system can adjust roll loadings, temperatures, and even roll crown profiles (in the case of variable crown or controlled-nip rolls) to maintain optimal conditions. For instance, if sensors detect higher moisture content on one side of the web in the press section, the system can slightly adjust the press roll loading profile to increase dewatering in that specific area. In the calender stack, systems can adjust nip pressure or temperature zones to correct caliper or gloss variations across the sheet width. This level of dynamic optimization is impossible with older, manually adjusted rolls. It allows the machine to react instantly to subtle variations in the process, ensuring consistent high quality and maximizing throughput. The integration of smart sensors, data analytics, and automated control loops represents a significant leap in how paper machine rolls contribute to overall operational excellence. It highlights how performance optimization isn't just about the static properties of the rolls but also about the intelligent systems that manage their dynamic behavior during operation.

Addressing Common Challenges Through Roll Technology

Paper manufacturing faces numerous challenges, and many of these can be mitigated or overcome through innovative roll design and technology, further optimizing performance. Issues like barring (periodic variations in paper caliper or density), vibration, web breaks, and inconsistent surface properties are often directly linked to roll condition or function. For example, dynamic balancing and precise roll grinding are essential to prevent barring caused by vibrational issues. Developing roll covers with specific non-stick properties can significantly reduce the frequency of web breaks caused by the sheet sticking to the roll surface, particularly in the press or dryer sections. Special anti-corrosive roll materials and coatings are crucial in sections exposed to process chemicals, extending roll life and preventing surface degradation that would impact paper quality. Wear is an inevitable reality, but developing harder, more durable roll covers minimizes the need for frequent regrinding or replacement, thus increasing machine uptime and reducing maintenance costs. Furthermore, designing rolls for easier and quicker changing during maintenance shutdowns contributes directly to improving overall equipment effectiveness. Addressing these practical operational challenges head-on through improved roll technology is a tangible way to unlock higher performance levels in paper manufacturing.

Looking Ahead: Innovations in Roll Technology

The pursuit of performance optimization in paper manufacturing is ongoing, and innovation in roll technology continues to play a vital role. We see developments in materials science leading to even more durable, specialized, and environmentally friendly roll covers. Research into surface energy and texture aims to create rolls that interact optimally with the paper web and process fluids, reducing issues like sticking and improving transfer efficiency. Advances in sensor technology are allowing for even more precise, in-situ monitoring of roll condition and performance, enabling predictive maintenance and finer control adjustments. Furthermore, the integration of artificial intelligence and machine learning with process control systems promises to take dynamic roll optimization to the next level, predicting potential issues and adjusting roll parameters preemptively. Robotics is also being explored for roll handling and maintenance to improve safety and efficiency. The focus remains on maximizing water removal with minimal energy, achieving perfect sheet structure and surface properties, minimizing downtime, and reducing operational costs – all objectives heavily reliant on the performance of paper machine rolls. What new roll innovation do you think will have the biggest impact on paper quality or efficiency in the next decade?

In summary, it's clear that paper machine rolls are far more than simple rotating cylinders. They are sophisticated, engineered components whose diverse designs, materials, precision manufacturing, and intelligent operation are absolutely central to optimizing performance throughout the paper manufacturing process. From the initial dewatering in the press section to the final finish imparted by the calender rolls, every roll contributes significantly to speed, efficiency, energy consumption, raw material usage, and ultimately, the quality of the final product. Understanding how each type of roll functions and how its properties and maintenance impact the web is key to unlocking a machine's full potential. The continuous evolution of roll technology, driven by material science and control systems, is pivotal in addressing production challenges and pushing the boundaries of what's possible in paper manufacturing performance.

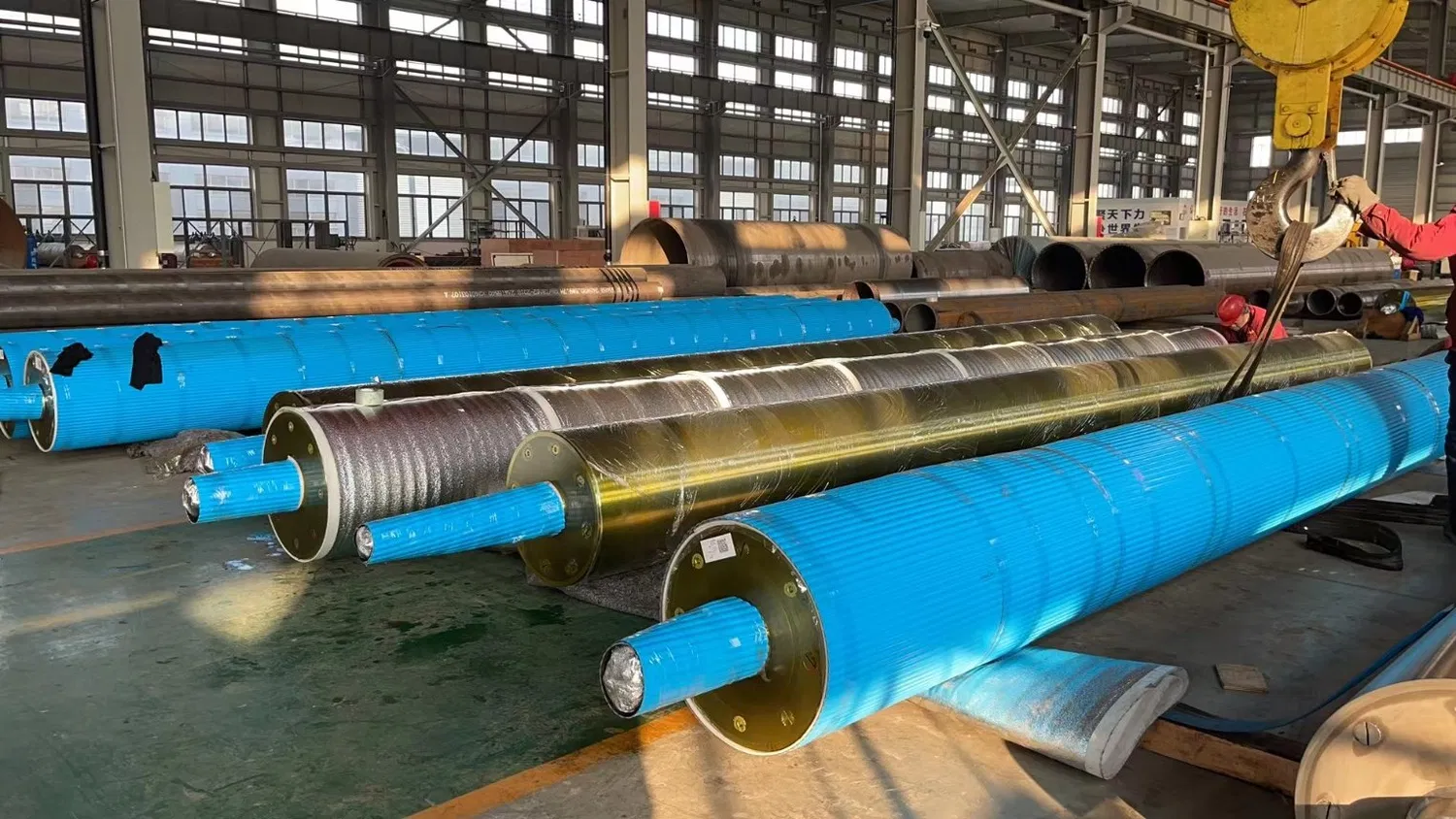

Our company specializes in providing solutions that address the critical role of paper machine rolls in optimizing performance. We offer a range of products and services, from advanced roll covers and materials engineered for specific applications to precision grinding and maintenance expertise, designed to help manufacturers overcome challenges like wear, vibration, and achieving desired sheet properties, directly contributing to improved uptime, efficiency, and paper quality.

For more detailed information, please visit our official website: Paper machine rolls