In the intricate dance of paper production, countless components work in harmony to transform raw pulp into the sheets we use every day. Among the most critical, yet often unseen heroes, are the Paper Mill Rolls. These cylindrical workhorses are far more than just simple rollers; they are precision-engineered instruments performing vital functions from dewatering and smoothing to pressing and drying the paper web as it journeys through the complex machinery of a paper machine. Frankly speaking, without properly functioning paper mill rolls, modern high-speed paper production would be impossible. Their performance directly impacts the efficiency of the mill, the quality of the final paper product, and the overall profitability of the operation. Understanding these crucial components is fundamental for anyone involved in the paper industry, from operators on the mill floor to engineers designing new processes or procurement teams sourcing replacement parts. Their design, material, maintenance, and application are subjects of continuous innovation and meticulous attention.

The Core Function of Paper Mill Rolls in Papermaking

Have you ever stopped to think about the sheer scale and speed at which paper is produced? A paper machine can be hundreds of meters long, processing a continuous web of fiber slurry at speeds exceeding 2000 meters per minute. At every stage of this journey, specialized Paper Mill Rolls play a non-negotiable role. In the press section, massive rolls equipped with sophisticated felts or shoes apply immense pressure to squeeze water out of the paper web, dramatically increasing its dryness before it reaches the energy-intensive dryer section. Interestingly enough, the geometry, cover material, and nip pressure of these press rolls are finely tuned to optimize dewatering without damaging the delicate web. Further down the line, in the dryer section, large-diameter cast iron rolls heated internally by steam transfer heat to evaporate remaining moisture. The surface condition and temperature uniformity of these dryer rolls are paramount for efficient drying and preventing defects. Finally, calender rolls polish and smooth the paper surface, controlling caliper, density, and finish properties, while other rolls like guide rolls and reel rolls ensure the web travels correctly and is wound up properly. Each roll type is specifically designed and manufactured to withstand the demanding environment – high temperatures, pressures, corrosive chemicals, and constant abrasion – proving just how specialized and durable these components must be.

Exploring Different Types of Paper Mill Rolls and Their Specific Roles

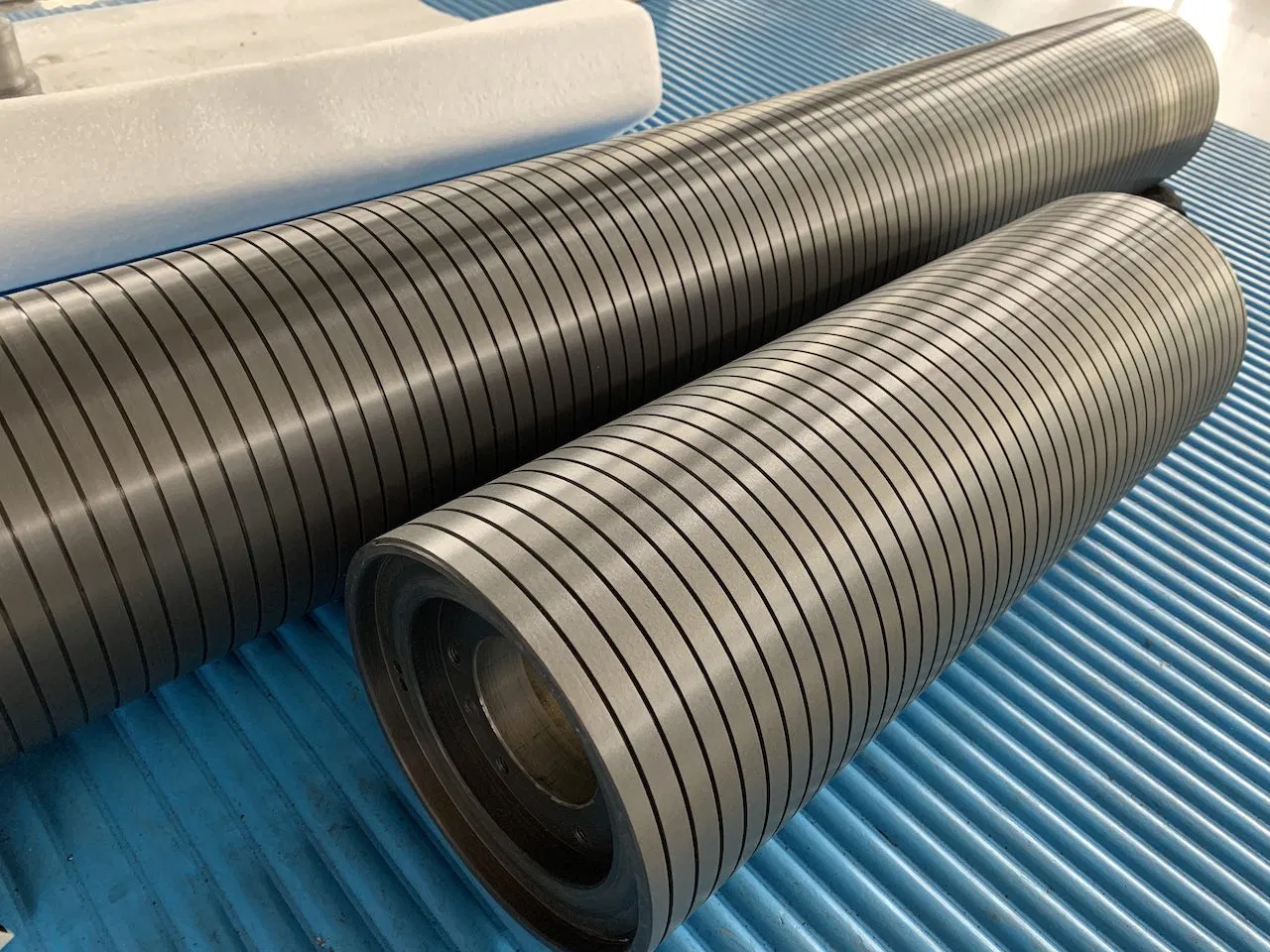

The sheer variety of Paper Mill Rolls reflects the diverse demands of the papermaking process. Press rolls, as mentioned, are designed primarily for dewatering. They can be plain rolls, grooved rolls, blind-drilled rolls, or highly sophisticated controlled crown rolls (CCR) that adjust their shape under load to maintain uniform pressure across the wide paper web. Covered press rolls utilize elastomeric or composite covers with specific hardness and surface properties tailored to the application, which significantly impacts dewatering efficiency and felt life. Then there are suction rolls, perforated shells under vacuum, used in forming, press, and reel sections to assist in water removal or web handling. Frankly speaking, the technology behind press roll covers alone is a field of extensive research, focusing on materials that resist wear, chemical attack, and temperature fluctuations while providing optimal nip conditions. Each type of press roll, from the suction press to the shoe press, represents a significant engineering achievement aimed at maximizing water removal with minimal energy and impact on paper properties.

Moving beyond dewatering, dryer rolls dominate the largest section of the paper machine. These are typically large-diameter cast iron cylinders, internally ribbed for strength and efficient heat transfer. They operate at high temperatures (up to 130°C or more) and are subject to significant thermal stress. The surface of dryer rolls needs to be smooth and free of defects to prevent marking the paper. While seemingly simpler than press rolls, ensuring uniform surface temperature and preventing shell corrosion from condensate and process chemistry are critical challenges. In my experience, issues with dryer roll surfaces or internal components are a common source of production slowdowns and quality problems. Maintaining their integrity is key to achieving the desired moisture profile in the paper, which directly impacts subsequent processes and the final paper's performance. The sheer number and size of these rolls make the dryer section a significant investment and a key area for maintenance focus in any paper mill.

Further refinement of the paper's properties occurs in the calender section, where calender rolls are the stars. These rolls, often made of chilled cast iron, steel, or covered with specialized materials, are used to compress and smooth the paper web. Soft nip calendering uses one hard and one soft-covered roll, while hard nip calendering uses two hard rolls. The pressure, temperature, and number of nips in the calender stack determine the paper's caliper (thickness), smoothness, gloss, and density. Achieving the desired paper finish consistently relies heavily on the precision and condition of the calender rolls. Beyond these major types, there are numerous other specialized Paper Mill Rolls, including reel rolls for winding the finished paper into large rolls, guide rolls for controlling web path and tension, and spreader rolls to eliminate wrinkles. Each serves a specific purpose in the complex journey of paper production, requiring unique designs and materials to perform effectively in its designated environment within the machine.

Materials, Coatings, and Manufacturing Precision for Optimal Performance

The operational demands placed upon Paper Mill Rolls are extreme, necessitating careful selection of materials and often specialized surface coatings. Rolls can be constructed from various materials, including cast iron, steel, granite, composites, or even polymers, depending on their function and location in the machine. For instance, dryer rolls are traditionally cast iron due to its excellent thermal conductivity and strength at high temperatures. Press roll shells might be cast iron, ductile iron, or fabricated steel, often with a corrosion-resistant cladding or lining. Granite rolls, historically used in presses and calenders, offer excellent hardness and non-stick properties but are increasingly being replaced by synthetic or composite alternatives. The choice of cover material for rolls is equally critical; elastomeric (rubber) covers offer resilience and grip, while polyurethane and composite covers provide superior durability, chemical resistance, and specific release properties. To be honest, the right cover can dramatically improve a roll's performance and lifespan.

Beyond the core materials, surface treatments and coatings play a vital role in enhancing the performance and longevity of Paper Mill Rolls. Hard chrome plating is commonly used for wear resistance on calender and press rolls. Thermal spray coatings, such as ceramics or carbides, offer exceptional hardness, corrosion resistance, and specific surface textures or release properties needed for certain applications, like dryer cylinders or specialized press rolls. The manufacturing process itself is a testament to precision engineering. Rolls must be machined to extremely tight tolerances for diameter, straightness, and surface finish. Balancing is also critical, especially for high-speed rolls, to prevent vibration that could damage the machine or affect paper quality. Many experts agree that slight imperfections in geometry or balance can lead to uneven wear, barring, or vibration issues down the line, significantly impacting efficiency. Ensuring dimensional accuracy and surface integrity through rigorous quality control is non-negotiable for any reputable paper mill roll manufacturer.

Maintaining Paper Mill Rolls for Peak Efficiency and Longevity

Investing in high-quality Paper Mill Rolls is just the first step; their sustained performance hinges on a comprehensive and proactive maintenance program. Regular inspection is essential to identify signs of wear, corrosion, damage, or cover degradation before they lead to catastrophic failure or impact paper quality. This includes visual inspections, non-destructive testing (NDT) methods like ultrasonic testing to check shell integrity, and dimensional checks. Grinding the roll surface is a common maintenance task to restore original geometry, remove wear, and improve surface finish. The frequency and precision of grinding are crucial; improper grinding can induce stress or create surface defects. Similarly, repairing damaged roll covers or shells requires specialized expertise and equipment. Many mills utilize roll service centers equipped with large grinding machines, balancing equipment, and NDT capabilities for this critical maintenance. Proactive maintenance, including scheduled grinding and inspection based on run time or condition monitoring, is far more cost-effective than reactive repairs after a failure occurs. Effective **paper machine rolls maintenance** planning is key to minimizing downtime and maximizing the operational life of these expensive assets.

The Direct Link Between Roll Condition and Paper Quality

The condition of Paper Mill Rolls has a profound and direct impact on the quality of the paper being produced. Uneven wear or damage on press rolls can lead to non-uniform dewatering across the web width, resulting in variations in moisture profile that cause curl or uneven drying in the dryer section. Defects on dryer roll surfaces can mark the paper or lead to differential drying. Worn or damaged calender rolls directly affect the paper's thickness uniformity (caliper), smoothness, gloss, and density. Barring, a pattern of alternating thick and thin bands in the paper, is often caused by vibrations or defects in rolls, particularly in the calender or reel sections. Surface imperfections like pits, scratches, or corrosion on any roll can transfer to the paper web, creating visible defects. Maintaining pristine roll surfaces and correct geometry is therefore not just about machine efficiency; it's fundamental to producing paper that meets stringent quality specifications for appearance, printability, and performance. Any compromise in roll condition inevitably leads to a compromise in the final paper product, underscoring the importance of investing in quality rolls and their proper upkeep.

Partnering for Excellence in Paper Mill Roll Solutions

Given the critical nature and technical complexity of Paper Mill Rolls, selecting the right supplier and partner is paramount. A reliable partner understands the unique demands of your specific paper machine and grade of paper. They can provide guidance on the most appropriate roll types, materials, and covers for your applications, whether you need high-performance press rolls for maximum dewatering or precision **calender rolls for paper production** with a specific finish. Beyond supplying new rolls, the best partners offer comprehensive services, including expert advice on roll design, material selection, and maintenance strategies. We understand the challenges paper mills face, from the need for increased efficiency to improving paper quality and extending component life. Our focus is on providing solutions that address these specific needs, offering high-quality manufacturing combined with deep technical expertise to help you optimize your paper machine's performance. We aim to be more than just a supplier; we strive to be a valuable resource for troubleshooting, maintenance planning, and optimizing your roll assets throughout their lifecycle, ensuring you get the most value from your investment in these critical components.

In conclusion, Paper Mill Rolls are indispensable components in the complex process of papermaking, each type playing a specific role that collectively determines the efficiency of production and the quality of the final product. From the demanding dewatering in the press section to the final smoothing in the calender, the performance of these rolls is non-negotiable. Investing in high-quality rolls, manufactured to exacting tolerances with appropriate materials and coatings, and implementing a rigorous **paper machine rolls maintenance** program are essential steps for any paper mill seeking to achieve high efficiency, minimize downtime, and consistently produce high-quality paper. Don't underestimate the impact these seemingly simple cylinders have; they are truly the backbone of the paper machine. Ensuring their optimal condition through expert selection, precision manufacturing, and proactive maintenance is a direct investment in the mill's success. Ready to explore how optimizing your paper mill rolls can transform your production? The next step is to connect with experts who can assess your specific needs and provide tailored solutions.

For more detailed information, please visit our official website: Paper Mill Rolls