The heartbeat of any high-speed paper machine lies within its intricate system of rollers. These components, seemingly simple cylinders, perform critical functions throughout the paper production process – from forming and pressing to drying and finishing. The performance, reliability, and lifespan of these rollers directly impact the machine's efficiency, paper quality, and ultimately, the mill's profitability. Choosing the right partner for these vital components is paramount. This is where the expertise of a dedicated paper machine roller manufacturer becomes indispensable. It's not just about producing a cylinder; it's about engineering a precision tool designed to withstand extreme conditions, high speeds, and continuous operation, ensuring seamless production flow day after day. Understanding the complexity and demands placed on these rollers is the first step in appreciating the specialized knowledge required for their manufacturing and maintenance.

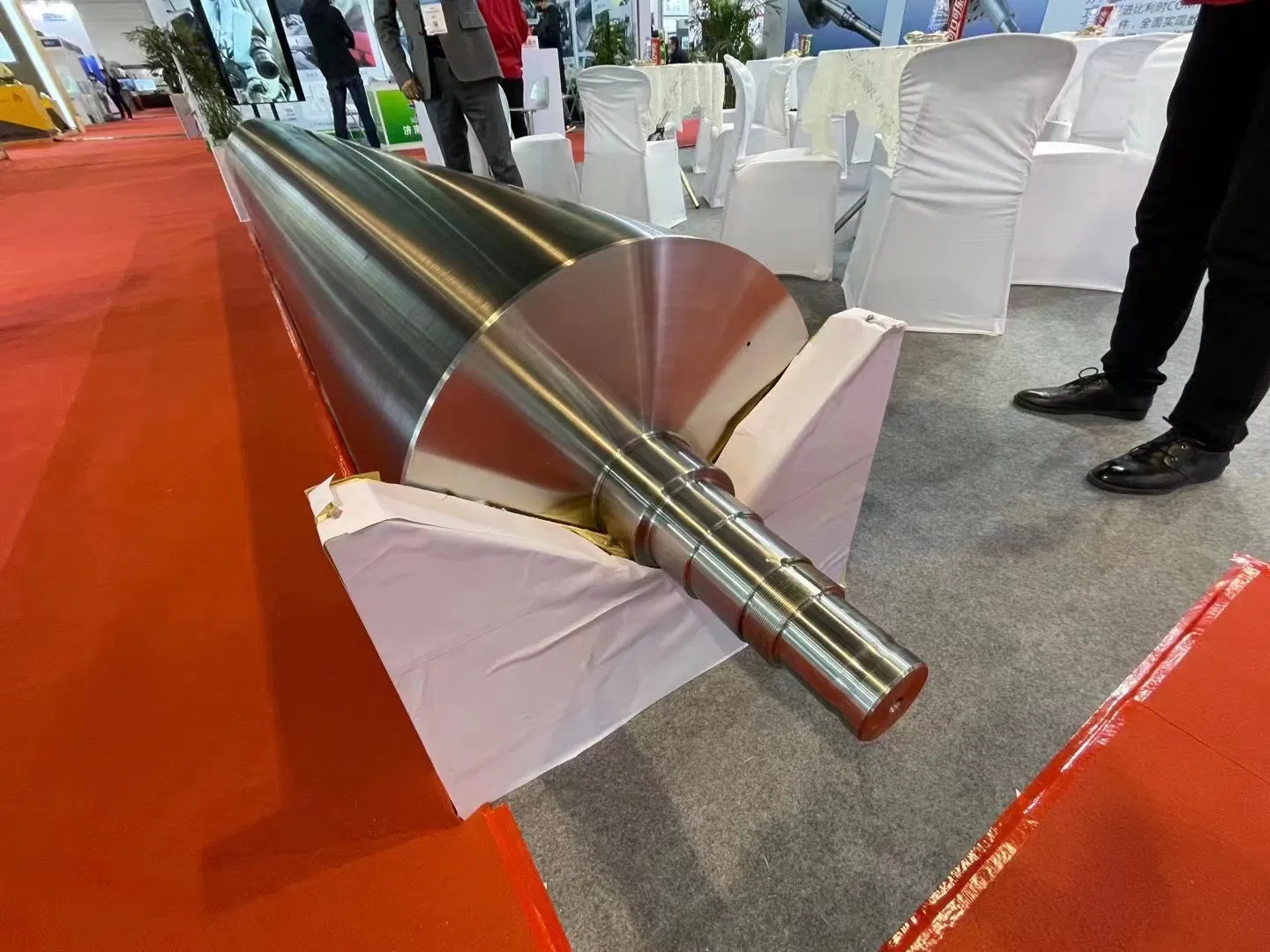

Paper machine rollers come in a surprising variety, each designed for a specific stage of the process. For example, forming rolls drain water from the pulp slurry to create the paper sheet, press rolls dewater the sheet further using pressure, and dryer rolls use heat to remove remaining moisture. Guide rolls ensure the web travels correctly, while calender rolls smooth the surface. Each type requires unique specifications regarding material composition, surface finish, diameter, length, and internal structure. The tolerances for these specifications are incredibly tight. A slight deviation can lead to uneven moisture profiles, web breaks, vibrations, or poor paper quality, halting production and costing valuable time and resources. This level of precision demands a manufacturer with extensive experience, deep technical knowledge, and state-of-the-art manufacturing capabilities. Frankly speaking, there's no room for error when producing components expected to perform under such demanding conditions.

The materials and surface coatings applied to paper machine rollers are crucial determinants of their performance and longevity. Steel, cast iron, and composite materials are common substrates, each chosen for its structural integrity and suitability for the specific roll's function. However, it's often the surface treatment that provides the necessary properties like wear resistance, corrosion resistance, release characteristics, and friction control. Rubber covers, ceramic coatings, hard chrome plating, and specialized polymer layers are applied through sophisticated processes. The selection of the appropriate cover or coating depends heavily on the operating environment – temperature, moisture, chemical exposure, and the type of paper being produced. A well-chosen coating can significantly extend the life of a roll and improve paper quality, but it requires a manufacturer who understands the complex interplay between materials, process conditions, and desired outcomes. Have you ever wondered why one roll cover lasts significantly longer than another in seemingly identical applications?

Manufacturing a paper machine roller is a complex undertaking that goes far beyond simple machining. It involves precision engineering, material science, thermal treatment, dynamic balancing, and rigorous quality control at every step. From the initial design phase, considering factors like deflection, thermal expansion, and critical speed, to the final surface grinding and balancing, every process is critical. Balancing, in particular, is essential for high-speed operation. An unbalanced roll can cause severe vibrations, leading to machine damage, reduced paper quality, and safety hazards. Dynamic balancing at operating speeds is a highly specialized skill. Furthermore, many modern paper machines require custom paper machine rollers designed to fit existing frame structures or meet unique process requirements. This necessitates close collaboration between the mill's engineers and the manufacturer's design team, ensuring the replacement or upgrade fits perfectly and performs optimally. It's worth noting that this level of customization is a hallmark of a truly capable manufacturer.

The challenges faced in the daily operation of paper machines translate directly into the challenges a roller manufacturer must overcome. Rollers are subjected to constant wear from the paper web and other machine components, corrosive chemicals used in the pulp and paper process, high temperatures, and immense pressures. Maintaining the dimensional stability and surface integrity of the roll over time is a significant engineering challenge. A manufacturer must not only build a robust roll initially but also understand how it will degrade over time and design it for maximum service life. They must also be adept at repairing and recovering worn rolls, bringing them back to original specifications through grinding, crowning, and reapplying covers or coatings. This lifecycle management service is often as valuable as the initial manufacturing capability. In my experience, working with a manufacturer who understands the full lifecycle reduces downtime and operational costs significantly.

Technical expertise and deep industry knowledge are non-negotiable requirements for a leading industrial roller manufacturing for pulp and paper. It's not enough to simply have advanced machinery; the engineering team must understand the nuances of papermaking, the stresses and strains on each roll position, and the impact of environmental factors. This knowledge informs everything from material selection and structural design to surface treatment and quality assurance protocols. A manufacturer's ability to provide technical support, troubleshoot performance issues, and recommend optimal roller configurations based on specific mill conditions is a key differentiator. They act less as a supplier and more as a technical partner, helping mills optimize their processes through superior roller technology. Interestingly enough, the subtle differences in roll design or material can have a dramatic impact on energy consumption or paper moisture profile.

Innovation is also a vital aspect of the paper machine roller industry. Manufacturers are constantly exploring new materials, coatings, and design concepts to improve roller performance. This includes developing covers that offer better release properties, reduce energy consumption by lowering friction, increase wear resistance for longer life, or incorporate smart features like embedded sensors for monitoring temperature or vibration. The move towards lighter, stronger composite materials is another area of development, offering potential benefits in reduced energy use and easier handling. Staying at the forefront of these technological advancements requires significant investment in research and development. A forward-thinking manufacturer is not just meeting today's needs but anticipating tomorrow's challenges in papermaking, from sustainability goals to increased machine speeds.

Choosing the right paper machine roller manufacturer is a strategic decision for any paper mill. What factors should you consider beyond just the initial cost? Look at their track record, their engineering capabilities, the breadth of their product and service offerings, their quality control processes, and their ability to provide timely support and field service. Do they have experience with your specific type of paper machine or grade of paper? Can they offer customized solutions? Are they investing in new technologies? Asking these questions can help differentiate between a basic supplier and a true partner who can contribute to your long-term success. A reliable manufacturer is one you can trust not only for new rolls but also for expert repair and maintenance, ensuring your valuable assets are kept in optimal condition. Many experts agree that focusing on quality and partnership over lowest upfront cost pays dividends in reduced downtime and improved performance.

Ultimately, the goal is to minimize unplanned downtime, maximize machine efficiency, and consistently produce high-quality paper. Achieving this requires critical components like rollers to perform flawlessly under extreme stress. The expertise of a specialized paper machine roller manufacturer is essential in ensuring this. They provide not just the physical rolls but the engineering knowledge, manufacturing precision, and ongoing support necessary to keep a paper machine running at its peak. By partnering with a manufacturer who understands the specific demands of your operation, you gain access to solutions tailored to your needs, ensuring optimal performance and longevity of your rollers. This partnership approach is key to navigating the complexities of modern papermaking and ensuring your machine assets are a source of reliability and efficiency, not a bottleneck.

For mills seeking to optimize their operations and invest in roller technology that offers durability, efficiency, and performance, selecting a manufacturer with proven capability and a commitment to quality is the most important step. Our company specializes in designing, manufacturing, and servicing a wide range of paper machine rollers, leveraging decades of experience and cutting-edge technology to meet the unique requirements of the pulp and paper industry. We understand the pressures you face to maintain high production rates and quality standards, and our products and services are specifically developed to help you achieve these goals. We offer expert consultation, custom engineering, and comprehensive support to ensure your rollers perform reliably for years to come. If you're looking for a partner dedicated to excellence in roller manufacturing and service, consider exploring the solutions we offer.

For more detailed information, please visit our official website: paper machine roller manufacturer