Have you ever stopped to consider the intricate dance happening within a paper machine as raw pulp transforms into the finished sheets we use every day? It's a complex process, relying on a multitude of interconnected systems, but arguably none are as fundamentally critical to both the quality of the final product and the efficiency of the operation as the various **rolls for paper machine**. These cylindrical workhorses guide, press, dry, and finish the paper web at incredible speeds, under immense pressure and temperature variations. Their performance dictates everything from moisture content and caliper uniformity to surface smoothness and overall runnability. Frankly speaking, without rolls performing optimally in every section, producing consistent, high-quality paper is simply impossible. Their design, material composition, surface characteristics, and maintenance regime are paramount considerations for any paper manufacturer aiming for peak performance and profitability.

The Foundational Role of Forming and Press Section Rolls for Paper Machine

The journey of the paper web begins in the forming section, where a slurry of fibers and water is laid onto a moving screen. Here, forming rolls support the screen and facilitate initial water removal through gravity and vacuum. While seemingly simple, these rolls must withstand corrosive environments and minimize abrasion on the delicate forming fabric. Moving into the press section, the role of **rolls for paper machine** becomes exponentially more critical. This is where significant water removal occurs through mechanical pressure, compacting the fibrous web and increasing its strength. Press rolls, often covered with specialized rubber or polymer coatings, work in nips exerting tons of force per linear inch. The precise hardness, surface profile, and crown (slight taper) of these rolls are essential to ensure even pressure distribution across the entire width of the web, preventing streaks, crushing, and achieving target dryness levels before the drying section. Maintaining the integrity and surface quality of press rolls is a continuous challenge, requiring regular grinding and monitoring.

Precision Engineering for Optimal Pressing Performance

The success of the press section hinges on achieving uniform moisture profile and density in the paper web. This is a direct consequence of the geometry and surface condition of the press section **rolls for paper machine**. Modern press configurations utilize various roll types, including blind-drilled rolls, grooved rolls, and sometimes vacuum rolls, each designed to manage water expressed from the sheet and felt. Extended nip presses (ENPs) introduce a long, pressurized nip using a shoe press roll, drastically increasing dewatering efficiency. For these advanced systems, the shoe press roll's surface and the mating roll's cover material and crown are engineered to incredibly tight tolerances. Any deviation – wear, damage, or improper crowning – leads to non-uniform pressure, resulting in moisture variations that can cause breaks in subsequent sections or defects in the final product. Ensuring these rolls are perfectly aligned and their surfaces are in pristine condition is a cornerstone of effective paper machine operation.

The Heat and Pressure Challenge: Drying and Calender Rolls

Following the press section, the web enters the drying section, typically consisting of a series of large, steam-heated cylinders. These drying **rolls for paper machine** are usually made of cast iron and are designed to efficiently transfer heat to the paper web as it passes over them, supported by dryer fabrics. The temperature and pressure within these rolls are significant, and they must be engineered to handle these conditions safely while maintaining a smooth, clean surface. Build-up of contaminants or uneven heat distribution caused by internal issues can lead to uneven drying, affecting paper quality and increasing the risk of fires. Interestingly enough, the drying process is the most energy-intensive part of paper manufacturing, and efficient heat transfer from the rolls is crucial for reducing operational costs and environmental impact. Therefore, the internal condition and surface cleanliness of dryer rolls are paramount.

Achieving Desired Surface Properties with Calender Rolls

The final stages of paper production involve calendering and reeling. Calender stacks, comprising multiple **rolls for paper machine**, are used to smooth the paper surface, control caliper (thickness), and improve gloss. Soft nip calendering, which uses rolls with compliant covers against heated steel rolls, is common for many paper grades. Hard nip calendering, typically using chilled cast iron rolls, is used for grades requiring high density and smoothness. The surface finish and temperature control of calender rolls are absolutely critical for achieving the desired paper properties. Wear, scratches, or thermal profile issues on these rolls directly translate into surface defects on the paper, impacting its printability and appearance. Maintaining uniform temperature and perfectly smooth roll surfaces is a constant requirement, often involving specialized grinding and polishing techniques.

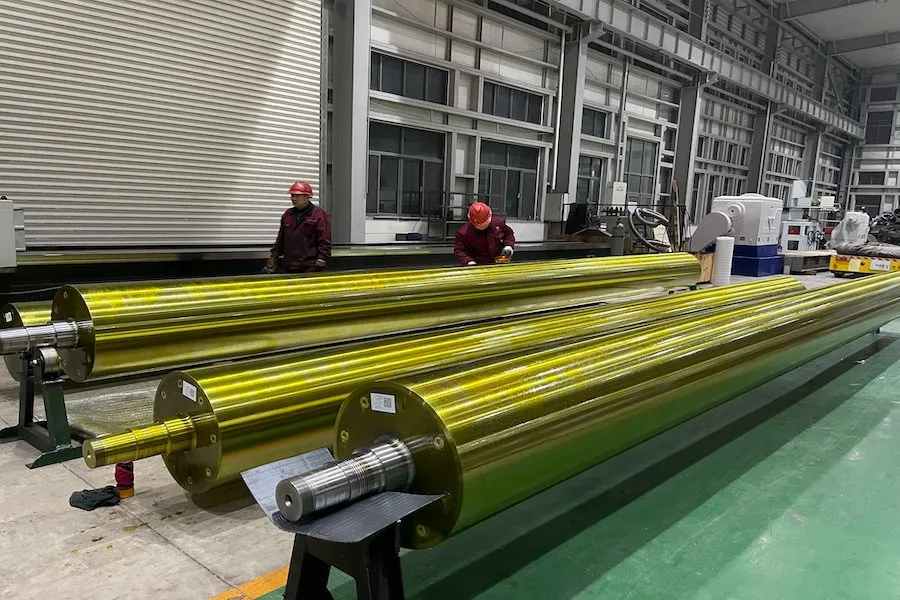

Materials, Coatings, and Surface Treatments for Rolls

The performance of **rolls for paper machine** is heavily reliant on the materials they are constructed from and the coatings applied to their surfaces. Core roll bodies are typically made from materials like cast iron, forged steel, or composite materials, chosen based on strength, rigidity, and resistance to operating conditions (pressure, temperature, corrosion). However, it's the roll cover or surface treatment that often defines the roll's function and durability. Rubber, polymers, composite materials, and ceramic or metallic coatings are applied to provide specific properties: grip for web handling, resilience for pressing, resistance to wear and chemicals, or specific surface finishes for calendering. The selection of the appropriate cover or coating is a complex decision based on the paper grade, machine speed, nip pressure, and operating environment. Abrasive pulps or sticky contaminants require highly resistant surfaces, while delicate paper grades demand covers that are gentle yet effective.

The Science Behind Durable and Functional Roll Covers

Developing and applying effective roll covers is a specialized science. For press rolls, covers need to withstand tremendous pressure cycles and resist deboning from the core, while also providing the right balance of hardness and resilience for dewatering. For calender rolls, covers must tolerate high temperatures and resist marking while imparting the desired surface finish. Materials like polyurethane, rubber blends, and composite layers are carefully formulated. Furthermore, surface treatments like hard chrome plating or thermal spray coatings (ceramics, carbides) are used on steel rolls, particularly in high-wear or high-temperature applications like calenders or some press positions. These treatments enhance durability, improve surface release properties (preventing sticking), and allow for specific surface textures. Frankly speaking, the right choice of material and surface treatment can significantly extend the lifespan of **rolls for paper machine** and improve overall machine efficiency, reducing downtime for maintenance and replacement.

Crucial Aspects of Paper Machine Roll Maintenance

Given their critical function and the demanding operating conditions, diligent **paper machine roll maintenance** is non-negotiable for ensuring reliable and efficient paper production. Regular inspection is the first line of defense, looking for signs of wear, damage, pitting, or cover deterioration. Monitoring parameters like roll temperature, vibration, and nip pressure provides valuable insights into performance and potential issues. Grinding the roll surface to restore its proper profile and smoothness is a routine maintenance activity, the frequency of which depends on the roll type, cover material, and operating conditions. Proper crowning is essential during grinding to compensate for roll deflection under load, ensuring uniform pressure across the web width. Balancing rolls is also critical, especially for high-speed machines, to prevent vibration that can damage the machine and affect paper quality.

Extending Roll Lifespan and Optimizing Performance Through Proactive Care

Beyond routine grinding and balancing, proactive maintenance strategies are key to extending the lifespan of **rolls for paper machine**. This includes proper storage and handling when rolls are not in the machine, preventing damage to delicate surfaces. Regular cleaning of roll surfaces while in operation, using appropriate showers and doctors (blades), prevents build-up that can cause defects or wear. Predictive maintenance techniques, such as thermal imaging to detect uneven temperatures or ultrasonic testing to check for internal defects, can identify potential problems before they lead to catastrophic failure. Investing in quality maintenance services, including expert grinding and cover application, pays dividends in reduced downtime and improved paper quality. Ignoring maintenance issues can lead to costly emergency repairs and prolonged production halts. It’s worth noting that implementing a robust **paper machine roll maintenance** program is one of the most effective ways to protect your investment and maximize productivity.

Troubleshooting Common Issues with Paper Machine Rolls

Despite best practices, problems with **rolls for paper machine** can still arise, leading to operational disruptions and quality defects. Common issues include barring (patterns of varying caliper or density on the paper web), vibrating rolls, premature cover wear or deboning, roll pitting or corrosion, and uneven drying or calendering due to surface issues. Barring, for instance, is often caused by non-uniform wear patterns or vibration in press or calender rolls. Premature cover wear can result from abrasive furnish, improper chemical use, or incorrect nip pressure. Identifying the root cause of these issues requires careful analysis of machine data, visual inspection of the rolls, and understanding the interaction between the roll, the web, and adjacent machine components. Troubleshooting often involves adjusting operating parameters, repairing or replacing the affected roll, or modifying maintenance practices. Frankly, addressing these issues promptly is vital to preventing escalation and minimizing financial losses.

The Impact of Roll Quality on Overall Machine Efficiency and Paper Quality

The quality and condition of **rolls for paper machine** have a direct and significant impact on the overall efficiency of the paper machine and the quality of the final product. Rolls that are improperly crowned or worn lead to uneven pressure and moisture profiles, increasing broke (waste paper), slowing down the machine speed (to prevent breaks), and producing paper that fails to meet specifications. Damaged or vibrating rolls can cause web breaks, leading to costly unscheduled downtime. Poorly performing dryer rolls result in inefficient drying, increasing energy consumption. Calender rolls with surface defects create imperfections on the paper surface. Investing in high-quality rolls and implementing a rigorous maintenance program pays off through increased machine speed, reduced broke, lower energy costs, and consistent production of paper that meets demanding quality standards. It's a ripple effect where the performance of individual components directly influences the entire process output.

Optimizing Performance: Selecting the Right Types of Paper Machine Rolls

Selecting the appropriate **types of paper machine rolls** for each specific application and paper grade is a crucial step in optimizing performance. The choice depends on factors like required nip pressure, operating temperature, desired surface finish on the paper, resistance to chemicals or wear, and machine speed. For instance, a newsprint machine might require different press roll covers compared to a machine producing fine writing paper or board. Similarly, the type of calender roll varies significantly depending on whether a matte finish or high gloss is desired. Consulting with experts in roll technology and manufacturing is essential to make informed decisions about roll selection, cover materials, and design features like internal cooling or heating systems. Matching the roll's capabilities to the specific demands of the machine section and product grade is fundamental to achieving maximum efficiency and desired product characteristics.

Our Commitment to Excellence in Paper Machine Rolls

Understanding the critical role these components play, our company is dedicated to providing high-quality **rolls for paper machine** and related services that address the challenges faced by paper manufacturers. We offer a range of solutions, from expert roll grinding and balancing to advanced cover application and manufacturing of new rolls designed for specific applications. Our focus is on helping you improve machine runnability, extend the lifespan of your rolls, reduce maintenance costs, and consistently produce paper of the highest quality. By leveraging our expertise in materials science, mechanical engineering, and paper machine operations, we partner with you to identify the best solutions for your specific needs. Whether it's upgrading existing rolls with more durable coatings or providing precise grinding services, our aim is to enhance your operational efficiency and product quality, ultimately contributing to your bottom line. We believe that with the right rolls and proper care, your paper machine can operate at its full potential.

For more detailed information, please visit our official website: Rolls for Paper Machine