The paper industry, a cornerstone of global commerce and communication, constantly seeks advancements to enhance efficiency, quality, and sustainability. At the heart of modern paper production lies roll technology, a critical component directly impacting the final product's characteristics and the overall manufacturing process. For years, the evolution of paper-making rolls has been a story of incremental improvements, but recent breakthroughs are ushering in a new era of transformative change. From novel materials and sophisticated coatings to integrated sensor technologies and revolutionary designs, the landscape of paper-making roll technology is undergoing a significant and exciting evolution. These innovations are not merely about tweaking existing systems; they represent a fundamental shift towards smarter, more efficient, and environmentally conscious paper production. Understanding these advancements is crucial for anyone involved in the paper industry, from manufacturers seeking to optimize their operations to researchers pushing the boundaries of material science and engineering.

Advanced Materials: The Foundation of Innovation

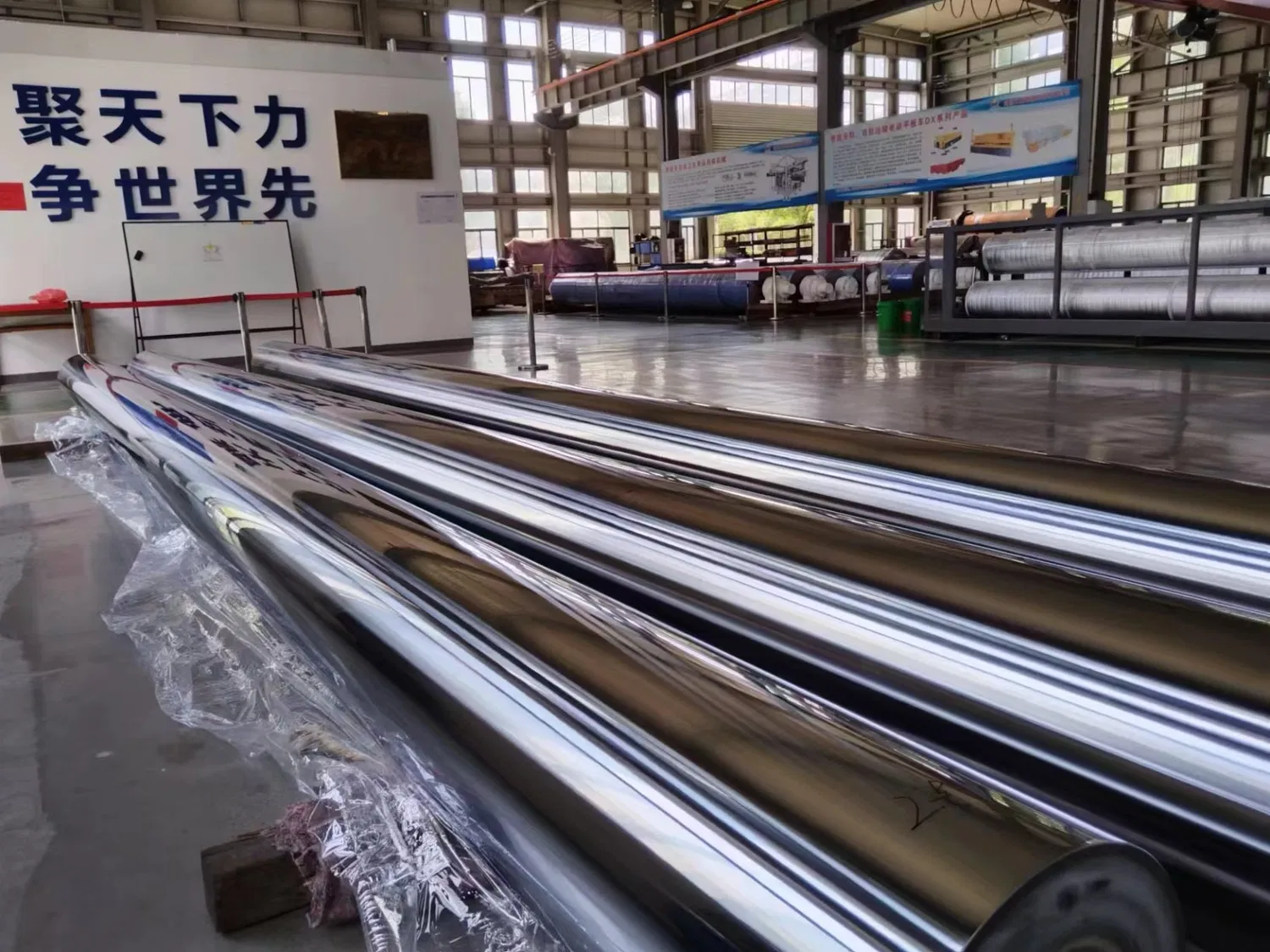

One of the most compelling areas of innovation in paper-making roll technology is the development and application of advanced materials. Traditionally, rolls were primarily constructed from steel and cast iron, materials chosen for their strength and durability. However, these conventional materials have limitations in terms of weight, corrosion resistance, and thermal conductivity. The push for lighter, more efficient, and longer-lasting rolls has spurred research into alternatives like composite materials, advanced polymers, and specialized alloys. Composites, for example, offer an exceptional strength-to-weight ratio, reducing the overall mass of the roll and consequently decreasing energy consumption during operation. Advanced polymers are being engineered to withstand the harsh conditions of paper production, including high temperatures, pressures, and chemical exposure, while also providing improved surface properties for better paper release and reduced sticking. Furthermore, specialized alloys are being developed with enhanced corrosion resistance, crucial in environments where rolls are exposed to aggressive chemicals used in pulping and bleaching processes. These material innovations are not just about replacing old materials with new ones; they are about fundamentally rethinking the performance characteristics of paper-making rolls and tailoring material properties to specific operational demands.

Revolutionary Coating Technologies: Enhancing Performance and Longevity

Beyond the core materials of the rolls themselves, coating technologies represent another dynamic frontier of innovation. Roll coatings are the outermost layer that directly interacts with the paper web, and their properties are paramount in determining paper quality, roll lifespan, and operational efficiency. Traditional coatings often focused on simple wear resistance, but modern coating technologies are far more sophisticated. We are seeing the rise of multi-layered coatings, each layer engineered with specific functionalities. For instance, a base layer might provide robust adhesion to the roll body, an intermediate layer could offer thermal insulation or damping properties, and the top layer, the working surface, is designed for optimal paper release, wear resistance, and even self-cleaning capabilities. Nanomaterials are also playing an increasingly important role in coating innovation. Nanoparticles incorporated into coatings can significantly enhance hardness, reduce friction, and improve chemical resistance. Furthermore, research is exploring "smart coatings" that can adapt their properties in response to changing process conditions, for example, adjusting surface roughness based on paper type or moisture content. These advancements in coating technology are extending roll life, reducing downtime for maintenance, and significantly improving the quality and consistency of the paper produced.

Smart Rolls: Integrating Sensors for Process Optimization

Perhaps one of the most transformative innovations in paper-making roll technology is the integration of sensors and data analytics, leading to the emergence of "smart rolls." Imagine rolls equipped with embedded sensors that can monitor temperature, pressure, vibration, and even moisture content in real-time, directly within the nip point. This data, continuously collected and analyzed, provides unprecedented insights into the paper-making process. Smart rolls can detect anomalies and deviations from optimal operating conditions instantly, allowing for proactive adjustments and preventing potential problems before they escalate into costly downtime or product defects. For example, temperature sensors can identify hotspots indicative of bearing wear or lubrication issues, vibration sensors can detect imbalances or misalignments, and pressure sensors can ensure uniform nip pressure across the roll width. The data generated by smart rolls can be fed into sophisticated process control systems, enabling closed-loop feedback and automated adjustments to optimize paper quality, reduce waste, and improve energy efficiency. This move towards data-driven paper production, enabled by smart roll technology, is a paradigm shift, transforming paper-making from a largely experience-based process to a highly precise and scientifically optimized operation.

Innovative Roll Designs and Geometries: Tailoring Performance

Beyond materials and coatings, the fundamental design and geometry of paper-making rolls are also undergoing significant innovation. Traditional roll designs were often based on standardized configurations, but modern paper production demands more specialized and tailored solutions. We are seeing the development of rolls with variable crown profiles, allowing for precise control of nip pressure distribution across the machine width, crucial for achieving uniform paper caliper and moisture content. Segmented rolls, where the roll surface is divided into independently controllable sections, are also gaining traction, offering even finer control over localized pressure and temperature. Furthermore, internal roll structures are being optimized using advanced finite element analysis and computational fluid dynamics to improve heat transfer, reduce vibration, and enhance structural integrity. For instance, innovative internal cooling channel designs can improve the efficiency of thermal rolls used in drying sections, leading to faster drying rates and reduced energy consumption. These advancements in roll design and geometry are not just about making rolls bigger or stronger; they are about engineering rolls with specific performance characteristics precisely tailored to the demands of different paper grades and production processes. Have you ever wondered how seemingly minor changes in roll shape could lead to such significant improvements in paper quality and production efficiency? It's a testament to the power of precision engineering in a traditionally heavy industry.

Automation and Precision Manufacturing: Ensuring Quality and Consistency

The advancements in paper-making roll technology are not limited to the rolls themselves; they extend to the manufacturing processes used to create these sophisticated components. Automation and precision manufacturing techniques are becoming increasingly critical in ensuring the quality, consistency, and reliability of modern paper-making rolls. Computer Numerical Control (CNC) machining, robotic welding, and automated coating application systems are replacing traditional manual processes, leading to tighter tolerances, improved surface finishes, and reduced manufacturing variability. These automated processes also enable the production of more complex roll designs and geometries that would be difficult or impossible to achieve with manual methods. Furthermore, advanced non-destructive testing (NDT) techniques, such as ultrasonic inspection and eddy current testing, are being integrated into the manufacturing process to ensure the structural integrity and quality of each roll before it leaves the factory. This focus on precision and automation in roll manufacturing is not just about improving production efficiency; it's about ensuring that every roll delivered to a paper mill meets the highest standards of performance and reliability, contributing to consistent paper quality and minimizing downtime. In my experience, the investment in advanced manufacturing technologies for paper-making rolls is a key factor differentiating leading roll suppliers from those lagging behind.

Sustainability and Eco-Friendly Solutions: Greening the Paper Industry

Sustainability is no longer a peripheral concern but a central driving force in the paper industry, and innovations in paper-making roll technology are playing a crucial role in this green transition. The pursuit of more energy-efficient paper production is a key focus, and lighter rolls, improved thermal conductivity, and optimized nip pressure control all contribute to reduced energy consumption. Longer-lasting rolls and coatings minimize the need for frequent replacements, reducing material waste and downtime. Furthermore, innovations in roll cleaning and maintenance technologies are also contributing to sustainability. For example, self-cleaning coatings and automated roll cleaning systems reduce the need for harsh chemical cleaning agents and minimize water usage. The development of bio-based and biodegradable roll components is another area of active research, aiming to further reduce the environmental footprint of paper-making rolls throughout their lifecycle. Frankly speaking, the paper industry is under increasing pressure to reduce its environmental impact, and the innovations we are seeing in roll technology are essential steps towards achieving a more sustainable and eco-friendly future for paper production. It's worth noting that these sustainable solutions are not just good for the environment; they often translate into cost savings for paper manufacturers through reduced energy consumption, material waste, and maintenance expenses.

Practical Applications and Real-World Impact: Examples in Action

The innovations discussed are not just theoretical concepts; they are being actively implemented in paper mills around the world, delivering tangible benefits. For example, paper mills using rolls with advanced composite materials are reporting significant reductions in drive motor load, leading to substantial energy savings. Mills adopting smart roll technology are experiencing improved process control, resulting in more consistent paper quality and reduced waste. Coating innovations are extending roll run times between regrinds, decreasing downtime and maintenance costs. In the production of high-quality printing and writing papers, rolls with precisely engineered crown profiles are ensuring uniform caliper and smoothness, enhancing printability. For packaging grades, rolls with optimized surface textures are improving paper strength and runnability on converting equipment. In tissue production, specialized roll designs are contributing to softer and bulkier tissue products. These are just a few examples of how innovations in paper-making roll technology are translating into real-world improvements in paper quality, production efficiency, and sustainability. The adoption of these new technologies is not just a trend; it's becoming a necessity for paper manufacturers to remain competitive in an increasingly demanding and environmentally conscious market.

Our Commitment to Innovation: Providing Cutting-Edge Solutions

At our company, we understand the critical role of paper-making roll technology in the success of the modern paper industry. We are committed to being at the forefront of innovation, developing and providing cutting-edge roll solutions that address the evolving needs of our customers. Our research and development efforts are focused on exploring and implementing the latest advancements in materials, coatings, sensor technology, and roll design. We offer a comprehensive range of high-performance rolls designed to optimize performance across all sections of the paper machine, from the forming section to the drying and calendering sections. Our smart roll solutions empower paper mills with real-time process insights, enabling data-driven optimization and proactive maintenance. We also prioritize sustainability, offering eco-friendly roll options and technologies that contribute to reduced energy consumption and waste. By partnering with us, paper manufacturers gain access to innovative roll solutions that enhance paper quality, improve production efficiency, reduce operating costs, and support their sustainability goals. We believe that the future of paper-making lies in continuous innovation, and we are dedicated to helping our customers stay ahead of the curve with the most advanced roll technology available.

Conclusion: Embracing the Future of Paper-Making Roll Technology

The innovations in paper-making roll technology are truly exciting, representing a dynamic and transformative period for the paper industry. From advanced materials and revolutionary coatings to smart rolls and innovative designs, these advancements are driving significant improvements in paper quality, production efficiency, and sustainability. The integration of sensor technology and data analytics is ushering in a new era of data-driven paper production, while the focus on sustainability is ensuring a greener future for the industry. As paper manufacturers face increasing demands for higher quality, lower costs, and reduced environmental impact, embracing these innovations in roll technology is not just an option, but a necessity. The future of paper-making is inextricably linked to the continued evolution of roll technology, and the advancements we are seeing today are paving the way for a more efficient, sustainable, and innovative paper industry tomorrow. The journey of innovation in paper-making rolls is far from over; it's an ongoing process of discovery, refinement, and adaptation, and the possibilities are truly limitless.

For more detailed information, please visit our official website: paper-making rolls