In the paper manufacturing world, one size rarely fits all. A standard, off-the-shelf roll can create more problems than it solves, leading to inefficient dewatering, paper defects, and costly downtime. True operational excellence is achieved through components engineered for your specific machine. This is where precision manufacturing becomes critical.

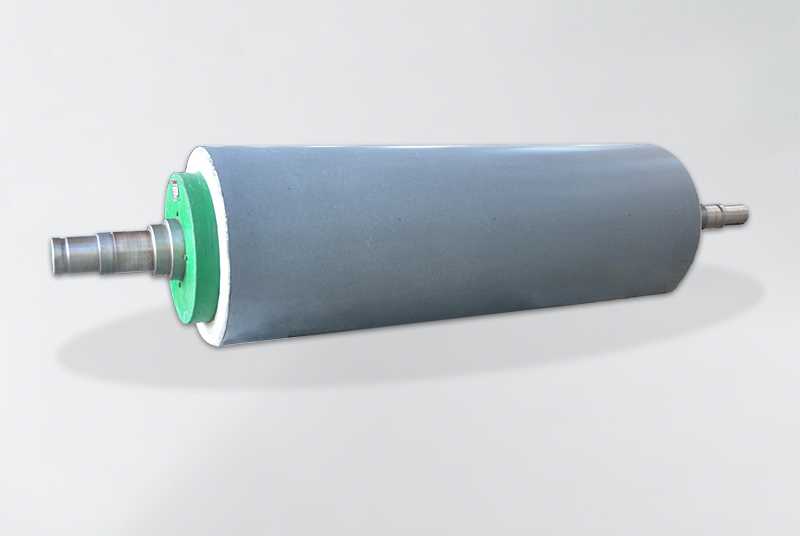

At Hs Machinery, we don't just supply granite rolls; we engineer custom solutions. Our entire process is built around turning your unique technical requirements into a high-performance, durable Custom Granite Stone Roll for Paper Making Machine.

Why Customization is Non-Negotiable for Paper Machine Rolls

Every paper machine has its own personality, defined by its width, speed, press configuration, and the type of paper it produces—from delicate tissue paper to robust linerboard. A generic roll fails to account for these variables, leading to:

- Uneven Nip Pressure: An incorrect crown profile on the roll results in an uneven pressure distribution, causing wet streaks and dry edges in the final paper sheet.

- Vibration and Bearing Wear: A roll not dynamically balanced for your machine's specific operating speed will cause harmful vibrations, leading to premature bearing failure.

- Compatibility Issues: Mismatched journal heads, bearing housings, or overall dimensions can make installation a nightmare, if not impossible.

Our philosophy is simple: a custom granite stone roll is not a luxury, it's a fundamental requirement for achieving consistent quality and peak production efficiency.

The Hs Machinery Blueprint: From Drawing to Delivery

How do we ensure every roll perfectly matches your needs? We follow a meticulous, multi-stage process that guarantees precision at every turn.

Step 1: In-depth Technical Consultation

Our process begins with your engineering team. We review your technical drawings (or help you create them), discussing critical parameters like crown requirements, linear pressure, operating speed, and the chemical environment of your pulp.

Step 2: Intelligent Raw Material Sourcing

Based on the application, we select a specific granite block. A roll for a high-speed newsprint machine requires different material properties than one for a slow, high-pressure pulp-drying machine. We ultrasonically test every block to ensure it is free from internal defects that could lead to failure under stress.

Step 3: Precision Machining and Grinding

This is where our expertise shines. Using state-of-the-art CNC lathes and grinders, we machine the roll body and steel journal heads to exceptionally tight tolerances. The critical crown profile—whether parabolic or a more complex curve—is ground with micron-level accuracy to ensure a perfectly uniform nip.

Step 4: Secure Assembly and Dynamic Balancing

The steel shafts are press-fitted and bonded into the stone body using advanced techniques to create an inseparable bond. Afterwards, every single roll is dynamically balanced to an ISO G1.0 or G2.5 standard, guaranteeing vibration-free operation even at the highest speeds.

Our Promise: Verifiable Quality at Every Step

Before any roll leaves our factory, it undergoes a battery of quality control checks. A final inspection report is generated, which includes:

- Dimensional accuracy verification.

- Surface roughness measurements.

- Crown profile conformity check.

- A certified dynamic balancing report.

This transparent process gives you complete confidence that the roll you receive is the roll you ordered, built to perform and last.

Your Partner for Custom-Engineered Solutions

Don't let a poorly matched roll become the bottleneck in your production line. Partner with a manufacturer that respects the unique engineering of your paper machine. At Hs Machinery, we combine the timeless durability of natural granite with modern manufacturing precision.

Have a specific requirement? Let's build it together.

Submit your technical drawings to our engineering team for a no-obligation quote. Explore our full capabilities and learn more about our Custom Granite Stone Roll for Paper Making Machine.