By Hs Machinery | Expert Manufacturer in Paper Machinery Components

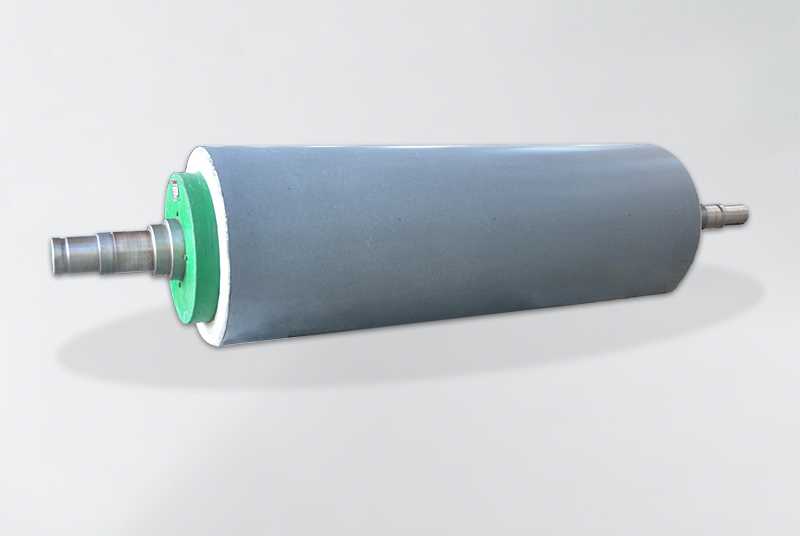

In the high-stakes environment of paper manufacturing, the press section is where efficiency is won or lost. Among the various components, the Granite Stone Roll for Paper Making Machine remains an irreplaceable asset for ensuring optimal dewatering and sheet release. While synthetic alternatives have entered the market, the natural properties of high-quality granite offer advantages that chemistry still struggles to replicate.

At Hs Machinery, we understand that sourcing heavy industrial components is not just about price—it is about reliability, longevity, and precision. As a direct manufacturer, we provide a comprehensive guide to understanding why our granite stone rolls are the preferred choice for paper mills globally, and how our direct-factory model benefits your bottom line.

The Science Behind the Stone: Why Granite is Superior for Press Sections

Not all stones are created equal. The granite used in paper machinery must possess specific geological characteristics. At Hs Machinery, we select stone blocks based on strict mineralogical criteria. Here is why natural granite is critical for your paper machine's top press roll position:

1. Natural Microporosity and Sheet Release

The most distinct advantage of a Granite Stone Roll for Paper Making Machine is its natural porosity. Unlike smooth synthetic surfaces, granite contains microscopic pores and a heterogeneous mineral structure (Quartz, Feldspar, Mica). This structure disrupts the water film between the paper web and the roll surface, ensuring excellent sheet release. This significantly reduces the "draw" required to pull the sheet, leading to fewer paper breaks and higher machine speeds.

2. Withstanding High Linear Nip Pressure

Modern paper machines operate under immense pressure. Our granite rolls are engineered to withstand high linear nip loads (up to 350 kN/m depending on diameter). The compressive strength of our selected granite ensures that the roll maintains its crown profile even under load, providing uniform moisture profile across the paper sheet.

3. Resistance to Doctor Blade Wear

Doctoring is essential for keeping the roll clean. Granite’s natural hardness (typically 6-7 on the Mohs scale) allows it to withstand the constant friction of doctor blades without rapid degradation, unlike softer rubber covers that require frequent regrinding.

Technical Specifications: Hs Machinery Granite Rolls

We provide full customization to fit specific machine brands (such as Voith, Valmet, or domestic machines). Below are the standard technical parameters we adhere to:

| Parameter | Specification Standard |

|---|---|

| Material Source | Selected High-Quality Natural Granite (Uniform Texture) |

| Mohs Hardness | 6 - 7 |

| Compressive Strength | ≥ 200 MPa |

| Diameter Range | 300mm - 1600mm (Customizable) |

| Face Length | Up to 10,000mm |

| Speed Allowance | Designed for speeds up to 1200m/min (Balanced) |

| Shaft Head Material | 45# Forged Steel or 40Cr (Thermal Refined) |

From Quarry to Mill: Our Manufacturing Process

Transparency is key to trust. As a manufacturer, Hs Machinery controls every step of the production process to ensure the integrity of the Granite Stone Roll for Paper Making Machine.

- Block Selection: We use ultrasonic testing to detect any internal fissures or cracks in the raw granite block before machining begins.

- Rough Machining & Assembly: The stone body is bored, and high-strength steel shafts are inserted using a specialized anchoring adhesive and mechanical locking method to ensure zero slippage at high torque.

- Precision Grinding: Using heavy-duty CNC grinders, we achieve the precise crown (camber) required for your specific nip pressure curve.

- Dynamic Balancing: To prevent vibration that could damage your machine bearings, every roll is dynamically balanced to G1.0 or G2.5 ISO standards.

Granite vs. Synthetic/Rubber Rolls: A Cost-Benefit Analysis

We often get asked: "Should I switch to synthetic stone?" While synthetic rolls have their place, natural granite offers the best Total Cost of Ownership (TCO) for many applications.

Synthetic rolls are sensitive to temperature shocks and chemical solvents, which can cause surface blistering. Natural granite, however, is thermally stable and chemically inert. For mills producing Kraft paper, Corrugated medium, or Writing paper, the ROI on a natural granite roll is often superior due to its lifespan, which can exceed 10-15 years with proper care.

Frequently Asked Questions (FAQ)

How do you ship heavy granite rolls safely?

Shipping is a critical part of our service. Hs Machinery uses custom-made heavy-duty steel crates. The roll body is wrapped in thick felt and rubber protection, suspended within the crate to prevent any impact on the stone surface during ocean freight.

Can you repair a damaged granite roll?

It depends on the depth of the damage. Minor surface scratches can be ground out on-site or in our factory. However, deep cracks affecting the structural integrity usually require a replacement. We offer consultation services to assess your damaged rolls.

What constitutes the maintenance of a granite roll?

Regular inspection of the doctor blade pressure is vital to prevent scoring. Additionally, avoiding sudden thermal shocks (using extremely hot water on a cold roll) is crucial to prevent thermal cracking.

Partner with Hs Machinery

Choosing the right supplier for your press section components is a strategic decision. With Hs Machinery, you are not just buying a part; you are investing in decades of manufacturing expertise, direct factory pricing, and a commitment to quality that ensures your paper machine runs smoothly.

Stop overpaying specifically for trading markups. Work directly with the source.

Ready to improve your paper machine efficiency?

Contact our engineering team today for a technical drawing review and a competitive quote. For more details, please visit our website regarding the Granite Stone Roll for Paper Making Machine.