About the Author: Frank Carter is a 35-year veteran in the paper industry, having risen from a millwright apprentice to the Reliability and Maintenance Manager for one of North America's largest integrated mills. Frank's philosophy is simple: "Reactive maintenance is failure. Proactive reliability is profit." He has a reputation for his no-nonsense approach and his ability to diagnose the root cause of machinery failures that others miss.

My Manifesto: Sweat the Details on Rolls, or Suffer the Downtime

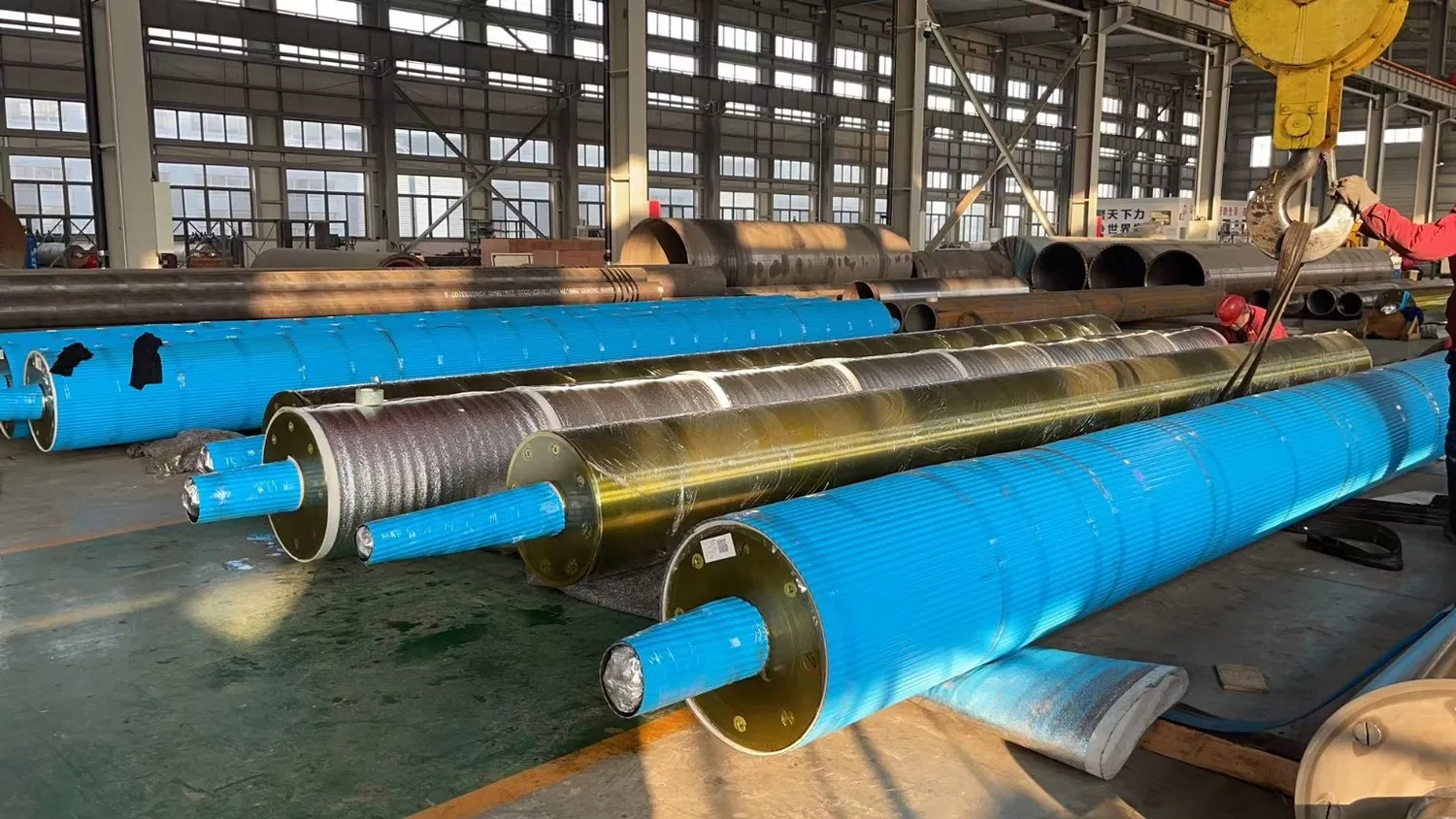

I've spent my entire career in the guts of paper mills. I can tell you from decades of experience and countless 3 AM call-outs that in a paper mill, silence is the most expensive sound in the world. And the most common cause of that deafening, profit-crushing silence is the failure of a critical roll. Not the pump, not the motor—the roll.

We, as maintenance and reliability professionals, are the guardians of uptime. We spend our days analyzing vibrations, checking lubrication, and aligning machinery. But I'm here to tell you that true reliability for paper mill rolls doesn't start on the factory floor. It starts with a fundamentally different way of thinking during the specification and procurement process. This is my manifesto for building a bulletproof operation, one roll at a time.

The Anatomy of Failure: Know Your Enemy

Before you can build for reliability, you must understand how things break. I’ve seen every failure imaginable, and they almost always trace back to a weakness in the roll's original design or material for its specific application.

Failure Mode 1: The Cover

Symptoms: Debonding (peeling off the core), blistering, cracking, or rapid wear. Root Causes: This is rarely a "bad cover." It's the wrong cover for the job. Chemical incompatibility with new process additives, thermal breakdown from high speeds, or insufficient abrasion resistance for a high-filler furnish. A cheap cover that debonds and wraps the felt is a multi-million dollar mistake.

Failure Mode 2: The Core & Journals

Symptoms: Fatigue cracks in the shell, bent rolls, or worn bearing seats on the journals. Root Causes: Under-engineered core design that can't handle the real-world nip loads. Inferior metallurgy (e.g., porous castings). Improper bearing fit tolerances from the manufacturer, leading to micromovement that destroys both the journal and the bearing. This is a catastrophic, often unrecoverable, failure.

Failure Mode 3: Vibration & Balance

Symptoms: Barring on the paper sheet, chatter marks, and chronically short bearing life. Root Cause: Inadequate dynamic balancing from the manufacturer. A roll without a certified balancing report confirming it meets the required ISO grade for your machine speed is a ticking time bomb. It will shake itself, its bearings, and the machine structure to an early grave.

The Reliability Checklist: How to Specify a Roll That Lasts

When you send a request for a quote, don't just send dimensions. You must send a detailed operational profile. A top-tier manufacturer will demand this information; a low-bidder won't. Here is what you MUST include:

- ✅ Full Chemical Profile: List every process chemical, pH range, and cleaning agent the roll will encounter.

- ✅ Complete Thermal Profile: Specify minimum, maximum, and average operating temperatures.

- ✅ Mechanical Load Data: Provide machine speed (MPM), nip load (kN/m), and furnish type (abrasiveness).

- ✅ Cover Performance Demands: Specify required hardness (P&J), abrasion resistance needs, and any special release properties.

- ✅ Required Standards: Mandate the dynamic balancing grade (e.g., ISO 1940 G1.6) and request NDT reports for the roll shell and journals.

Providing this data forces the manufacturer to engineer a solution, not just quote a product. It makes them accountable for the roll's performance in your mill.

Your Best Maintenance Partner Isn't on Your Payroll

Here's the truth: my best reliability partners over the years have been my equipment suppliers. A great roll manufacturer acts as an extension of your reliability team.

They aren't afraid of the detailed checklist above; they welcome it. They have the engineering depth to analyze your data and recommend the optimal combination of materials and design features. That is the philosophy behind a true manufacturing partner like ER88P. We build custom industrial rolls from the ground up, based on a deep understanding of your operational reality. Our quality control isn't just a department; it's a core principle designed to ensure that when our roll arrives at your mill, it's one less thing for your maintenance team to worry about.

Final Word: Buy Foresight, Not Just Steel

You can buy a cheaper roll, and you'll pay for it ten times over in downtime, lost production, and the frustration of your maintenance crew. Or, you can invest in a roll that has been intelligently engineered and meticulously manufactured for your specific conditions. You're not just buying steel and polyurethane; you're buying foresight, you're buying reliability, and most importantly, you're buying uptime.

Stop reacting to failures. Start building for reliability with superior paper mill rolls.