About the Author: Richard Sterling is the former Operations Director for a leading multi-national paper group, with over 30 years of experience managing mill turnarounds and capital expenditure projects. Now a consultant with Sterling Mill Operations, he advises on strategies that link engineering decisions directly to financial performance. Richard is a firm believer that the most significant gains in profitability are often hidden within a mill's core infrastructure.

Beyond the Spec Sheet: Viewing Rolls as a Capital Investment

Let's be candid. In a paper mill's P&L statement, uptime is revenue and unplanned downtime is a hemorrhage. As directors and managers, we scrutinize labor costs, energy consumption, and fiber prices. Yet, we often relegate one of the most critical components—the paper machine roll—to a simple line item in a procurement budget. This is a strategic error.

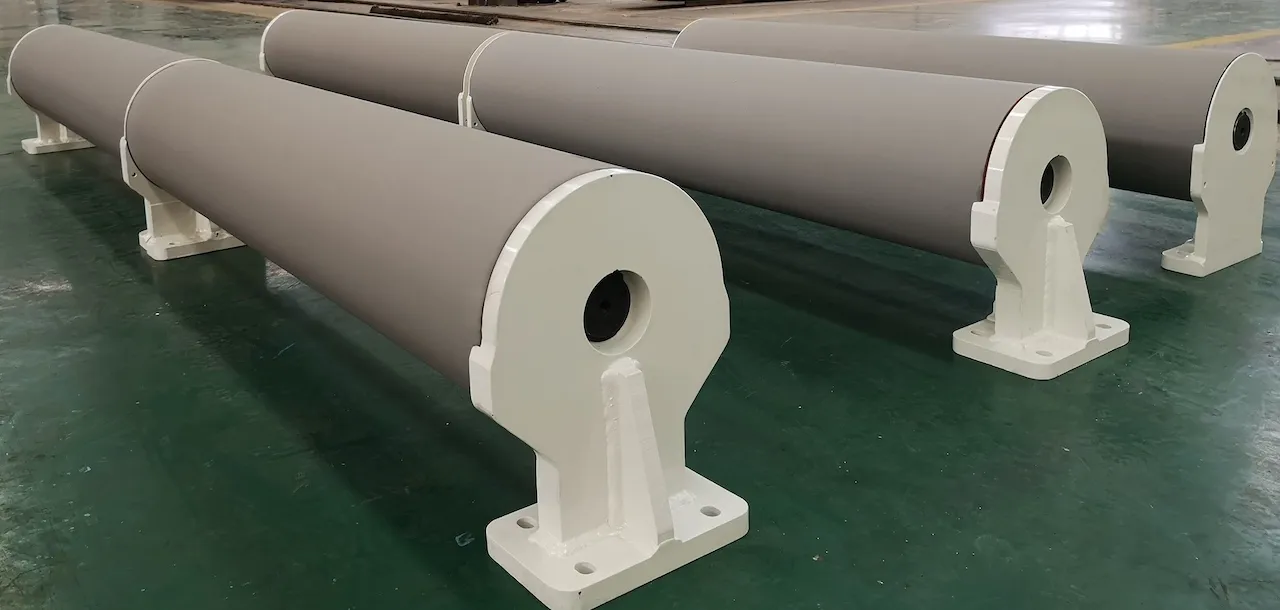

In my three decades of experience, I've learned that a paper machine roll is not a consumable part. It is a long-term capital investment with a profound impact on every key performance indicator, from machine speed and energy usage to the final quality and saleable tonnage of your product. The decision of which roll to buy, and from whom, is one of the highest-leverage choices a mill can make. This playbook is designed to shift your perspective from price tag to total cost of ownership (TCO) and long-term value.

A Roll is Not a Roll: An Ecosystem of Specialists

A paper machine is a hundred-meter-long chain, and its strength is dictated by its weakest link. Each section demands a different type of roll with highly specialized characteristics.

Forming Section Rolls (The Foundation)

Here, in a slurry of water and fiber, the sheet is born. Rolls like the breast roll, forming rolls, and couch roll are subjected to intense abrasion and corrosion. The primary demands are extreme wear resistance (often requiring advanced ceramic or composite covers) and optimal design for water drainage to set a good foundation for the rest of the machine.

Press Section Rolls (The Economic Engine)

This is where mills make or lose the most money on energy. Every additional 1% of water removed here by a high-performance press roll (be it grooved, blind-drilled, or suction) saves a fortune in thermal energy (gas or steam) in the dryer section. The focus here is on nip dynamics, cover materials (polyurethane, advanced rubber), and the structural integrity to withstand immense pressures.

Dryer Section & Finishing Rolls (The Signature)

Rolls in the dryer and finishing sections, like dryer cans, calender rolls, and reel spools, must perform reliably in harsh environments while imparting the final quality characteristics. Calender rolls, for example, require exceptionally hard and flawlessly smooth surfaces (chilled iron or chrome plating) to control sheet caliper, gloss, and smoothness. Their perfection defines your product's final signature.

The Anatomy of a Roll That Pays for Itself

What separates a roll that lasts 24 months from one that runs trouble-free for 60? It’s the engineering DNA—the details that don’t always appear on a basic quote.

Core Metallurgy: A roll shell made from centrifugally cast steel or high-quality ductile iron will have a superior grain structure and internal integrity compared to a cheaper alternative. This means better dimensional stability and resistance to fatigue over millions of revolutions.

Advanced Coatings & Covers: The surface is the business end. A premium manufacturer will offer a wide palette of options—tungsten carbide coatings for wear resistance against doctor blades, advanced polymer covers for specific chemical environments, and precision-ground chrome for mirror finishes.

Engineering Rigor: Was the roll designed using Finite Element Analysis (FEA) to predict how it will behave under your specific loads? Was it dynamically balanced to a high ISO grade (e.g., G1.0) to eliminate vibration? Was the shell checked for flaws using non-destructive testing (NDT)? These are the questions a director should be asking.

Evaluating a Roll Manufacturer: A Director's Checklist

The single greatest factor in securing long-term roll value is the choice of your manufacturing partner. Look beyond the quote and evaluate the supplier's capability as a strategic asset.

A partner like ER88P is structured to meet these director-level criteria. We don't just fabricate; we collaborate. By providing comprehensive engineering, transparent manufacturing with rigorous quality control, and full lifecycle support, we build custom paper rolls designed to maximize your operational efficiency and deliver the lowest total cost of ownership.

The Bottom Line

The initial purchase price of a paper machine roll is a fraction of its true cost over its operational life. When you factor in maintenance, energy consumption, and the immense cost of lost production from a premature failure, the value of investing in a premium, correctly engineered roll becomes crystal clear. It is a decision that pays dividends in reliability, quality, and profitability for years to come.

Make the strategic choice. Invest in reliability and performance with a world-class paper machine roll designed for your mill.