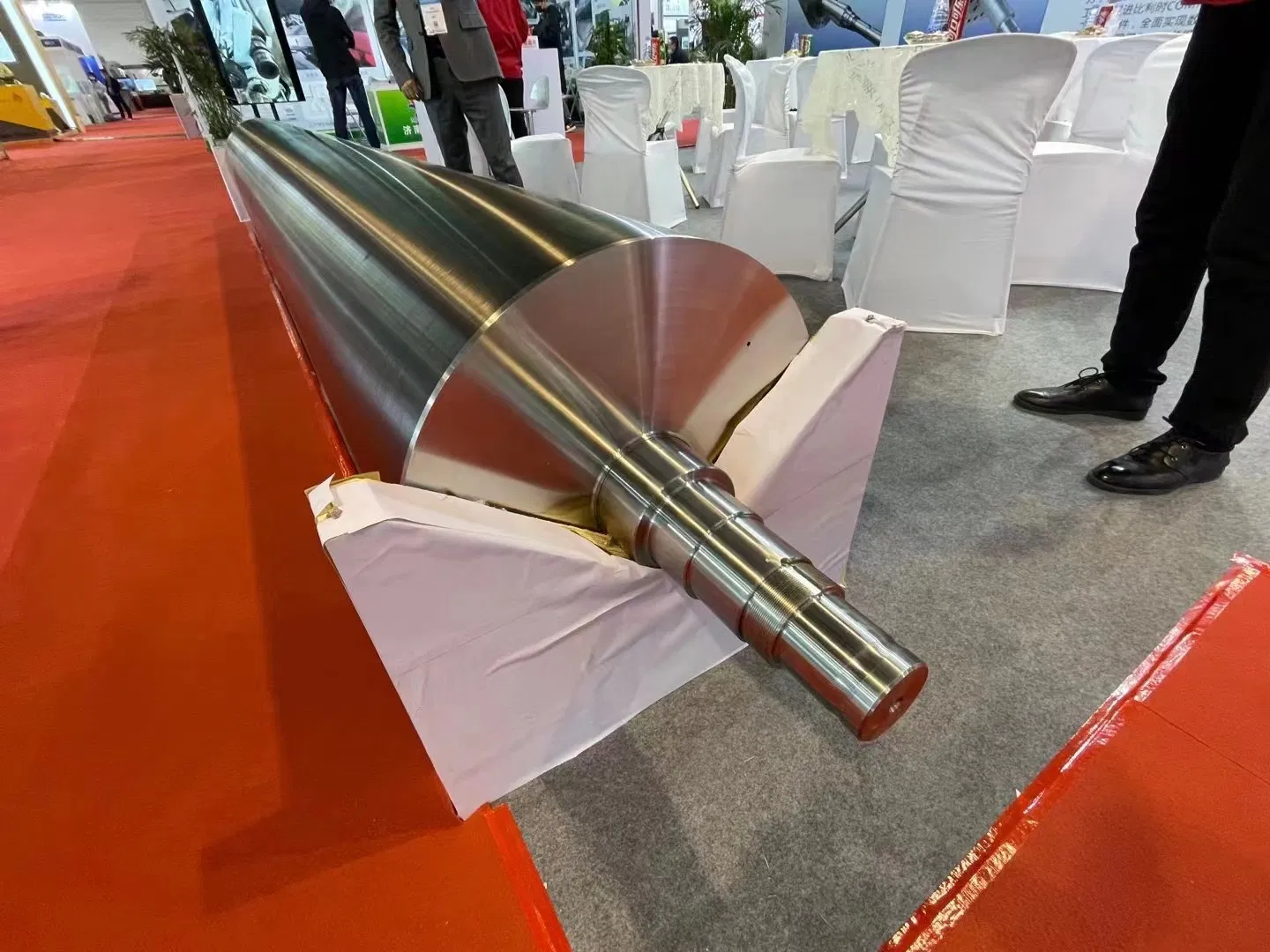

In the complex world of paper manufacturing, the quality of the final product is paramount. Every component in the paper machine plays a critical role, and perhaps none are more crucial than the various rolls that guide, press, dry, and finish the paper web. These rolls, often massive and heavy, are subjected to immense pressures, high temperatures, and constant friction. Over time, this relentless operation inevitably leads to wear, surface imperfections, and changes in the roll profile. These seemingly minor issues can have significant negative impacts, ranging from uneven moisture profiles and caliper variations in the paper to increased energy consumption and ultimately, costly machine downtime. Maintaining the precise geometry and surface finish of these rolls isn't just about keeping the machine running; it's fundamentally about ensuring consistent, high-quality paper production. This is where a professional **paper machine roll grinding service** becomes an indispensable partner for any paper mill striving for excellence and efficiency.

The Unseen Impact of Roll Wear on Paper Production

It's easy to overlook the gradual degradation of paper machine rolls, but the consequences are far-reaching. As rolls wear, their surfaces can develop grooves, pitting, or unevenness. The designed crown profile, which is critical for achieving uniform nip pressure across the full width of the paper web, can also change. Think about press rolls, for instance; if the crown is incorrect or the surface is rough, the pressure applied to dewater the sheet will be inconsistent. This leads to variations in moisture content, which directly affects paper strength, drying energy requirements, and final quality. Similarly, calender rolls with surface defects can emboss unwanted patterns onto the sheet or cause uneven gloss. Frankly speaking, any deviation from the ideal roll condition compromises the integrity of the paper web at various stages. This isn't merely an aesthetic problem; it impacts critical paper properties like caliper, smoothness, porosity, and tensile strength. Addressing these issues proactively through expert grinding services is not just maintenance; it's a strategic investment in product quality and operational stability.

Why Precision Roll Grinding is Non-Negotiable for Quality

Achieving high-quality paper consistently demands precision at every step, and roll grinding is a prime example. The goal of grinding isn't just to make the roll round again; it's about restoring its exact specifications, including diameter, roundness (concentricity), straightness, surface finish (roughness, parallelism), and the critical crown profile. Modern paper grades often have tight specifications, and even slight inaccuracies in roll geometry can make it impossible to meet these requirements. For example, a press roll needs a specific crown to counteract roll deflection under load, ensuring uniform nip pressure. If the grinding process doesn't precisely recreate this crown, you'll end up with uneven dewatering and potential web breaks or quality rejects. Similarly, rolls in the size press or coating section require extremely fine surface finishes to apply coatings uniformly. A professional **paper machine roll grinding service** utilizes specialized machinery and skilled technicians to achieve these demanding tolerances, ensuring that each roll performs exactly as designed, contributing positively to the final paper quality rather than detracting from it.

Benefits Beyond Quality: Extending Roll Life and Reducing Costs

While improved paper quality is a primary driver for utilizing roll grinding services, the economic benefits are equally compelling. Regularly maintaining rolls through grinding significantly extends their operational lifespan. Instead of replacing expensive rolls prematurely due to wear or damage, grinding allows you to restore them to their optimal condition multiple times. This translates directly into substantial cost savings on capital expenditure. Furthermore, well-maintained rolls contribute to overall machine efficiency. Uniform nip pressures reduce the risk of web breaks, minimizing costly downtime and lost production. Efficient dewatering in the press section reduces the energy required in the dryer section, leading to lower operational costs. Smooth, accurate roll surfaces also reduce vibration and wear on bearings and other machine components, lowering maintenance costs elsewhere. It's worth noting that investing in routine grinding is far more cost-effective than dealing with the fallout of roll failure, which can include emergency repairs, rushed replacements, and prolonged production halts. A strategic approach to roll maintenance through expert grinding is a clear path to enhanced profitability.

Selecting the Right Expertise for Your Paper Rolls

Choosing a provider for your **paper machine roll grinding service** is a decision that shouldn't be taken lightly. Not all grinding services are created equal, and the specific needs of paper machine rolls require specialized knowledge and equipment. You need a partner who understands the unique characteristics of different roll types – whether it's a granite roll in the press section, a soft-covered roll in the size press, or a chilled cast iron calender roll. The provider should have experience with various roll materials and coverings, as each requires specific grinding techniques and abrasive wheels to achieve the desired surface finish without causing damage. Their equipment must be capable of handling the size and weight of your rolls and be able to achieve extremely tight tolerances for roundness, straightness, and crown profile. Ideally, they should also offer comprehensive inspection services to assess roll condition before and after grinding, providing detailed reports. In my experience, a service provider that combines state-of-the-art technology with deep industry knowledge and a commitment to quality control is essential for realizing the full benefits of professional roll grinding.

On-Site vs. Off-Site Roll Grinding: Which is Right for You?

When considering roll grinding, one key logistical decision is whether to perform the service on-site or off-site. Both options have their merits, and the best choice often depends on factors like roll size, machine layout, the nature of the required grinding, and available downtime. Off-site grinding, performed at the service provider's facility, typically allows for the highest degree of precision and control. Specialized grinding machines in a controlled environment can achieve exceptionally tight tolerances and handle complex profiles. However, it requires removing the roll from the machine and transporting it, incurring logistics costs and potentially longer downtime. On the other hand, **on-site paper roll maintenance**, particularly grinding, can significantly reduce downtime as the roll remains in the machine. This is often feasible for minor surface conditioning or refreshing a crown. The feasibility and accuracy of on-site grinding depend heavily on the portable grinding equipment available and the skill of the technicians. Many mills utilize a combination approach, sending critical rolls off-site for comprehensive restoration while performing lighter maintenance tasks or spot grinding on-site when possible. Discussing the pros and cons with your service provider based on your specific rolls and operational constraints is crucial.

Precision Technology Driving Modern Roll Maintenance

The field of paper machine roll grinding has evolved significantly thanks to advancements in technology. Modern grinding machines incorporate sophisticated control systems, often utilizing CNC (Computer Numerical Control) technology, to achieve unparalleled accuracy in profile generation and surface finish. These machines can precisely replicate complex parabolic or multi-segment crowns essential for optimum performance under varying load conditions. Advanced measurement systems, such as laser-based profile scanners, allow for highly accurate assessment of the roll's condition before and after grinding, ensuring that the required specifications are met. Furthermore, developments in grinding wheels and abrasives allow service providers to work effectively with a wide range of roll materials and coatings, from hard ceramics to softer rubber or composite coverings. This technological sophistication ensures that the **paper machine roll grinding service** delivered today is far more precise and effective than in the past, capable of restoring even highly specialized rolls to their original performance capabilities. This level of precision is indispensable for mills producing high-specification paper grades.

Addressing Common Challenges in Roll Grinding

Even with advanced technology, paper machine roll grinding presents unique challenges. One common issue is dealing with different roll coverings and core materials, each requiring specific grinding parameters to avoid damage or achieve the desired finish. Rubber or polyurethane covers, for instance, require different speeds and feeds than hard metal or ceramic surfaces. Another challenge is ensuring perfect concentricity – making sure the roll is perfectly round around its axis of rotation. Any eccentricity, even slight, can cause vibration and uneven pressure distribution in the nip. Grinding a precise, symmetrical crown profile is also technically demanding, especially on large rolls that may deflect under their own weight or during the grinding process itself. Overcoming these challenges requires not only advanced equipment but also the deep expertise and experience of the grinding technicians. They must understand the nuances of different roll types, anticipate potential issues, and apply the correct techniques to achieve the desired outcome. A premium **paper machine roll grinding service** distinguishes itself by its ability to consistently overcome these technical hurdles, delivering reliably precise results.

The Long-Term Value of Investing in Roll Grinding Services

Considering the discussion above, it's clear that investing in professional paper machine roll grinding service is not just a necessary expense but a strategic investment with significant long-term returns. By maintaining rolls in peak condition, mills can achieve higher and more consistent paper quality, reduce waste and rejects, and minimize energy consumption. The extended lifespan of rolls and reduced downtime lead to substantial savings in maintenance and capital costs. Furthermore, machines running with properly maintained rolls operate more smoothly, reducing wear and tear on other components and lowering the risk of unexpected breakdowns. Have you ever calculated the true cost of unscheduled downtime caused by roll issues? It's often astronomical, far exceeding the cost of preventative grinding. By partnering with a reputable provider for your **precision roll grinding for paper machines**, you're not just maintaining equipment; you're safeguarding your production efficiency, product quality, and ultimately, your profitability in a competitive market. It's a fundamental aspect of effective asset management in the paper industry.

To be honest, overlooking the state of your paper machine rolls is a gamble no mill should take. Their condition is intrinsically linked to everything from web stability to energy consumption and final product characteristics. A proactive approach centered around regular, high-quality grinding service ensures these critical components perform at their best, year after year. It's a cornerstone of reliable paper production. What steps is your mill taking to ensure the precision and longevity of its rolls? Ensuring timely and accurate maintenance is key. Our services are specifically designed to address these challenges, offering the expertise and technology required for effective paper machine roll grinding, helping you achieve optimal machine performance and superior paper quality.

For more detailed information, please visit our official website: paper machine roll grinding service