In the complex symphony of a modern paper machine, every component plays a crucial role in transforming a watery slurry into a finished sheet. Among the most vital unsung heroes is the suction couch roll. Positioned early in the dewatering process, often just after the forming section, this specialized roll is tasked with a critical job: removing a significant amount of water from the newly formed paper web using vacuum technology. Its efficiency directly impacts everything that follows – from the performance of the press section to the final drying load, and ultimately, the quality and cost-effectiveness of the paper produced. Understanding the intricacies of the suction couch roll paper machine isn't just for maintenance crews; it's essential for anyone involved in optimizing the paper manufacturing process. Frankly speaking, a poorly performing couch roll can be a major bottleneck and source of frustration, leading to web breaks, uneven moisture profiles, and reduced machine speed. Getting this part right is fundamental to achieving high-speed, efficient production.

The Fundamental Principle: Vacuum Dewatering in Paper Machines

At its core, the function of a suction couch roll is elegant in its simplicity, yet complex in its execution. As the paper web, still largely water, moves from the forming fabric onto or over the couch roll, a vacuum is applied from within the roll shell. This vacuum creates a pressure differential, pulling water down through the web and the forming fabric, into the perforations of the roll shell, and then draining it away. This initial bulk dewatering step is incredibly important because removing water mechanically using vacuum is far more energy-efficient than removing it later through thermal drying. The more water you can get out here, the less steam is needed in the dryer section, leading to significant energy savings and cost reductions. To be honest, achieving optimal vacuum levels and consistent dewatering across the width of the roll is a delicate balance, influenced by factors like vacuum pump capacity, shell design, drilling pattern, and the effectiveness of the internal sealing strips. It sets the stage for all subsequent dewatering and affects final sheet properties.

Inside the Roll: Mechanics of Vacuum Generation

Delving deeper into the mechanics, the success of the suction couch roll paper machine hinges on its internal design. The roll shell itself is typically a large cylinder perforated with thousands of precisely drilled holes. Inside this shell, stationary vacuum boxes or zones are positioned against the inner surface. These boxes are connected to vacuum pumps, which draw air and water through the shell perforations. A crucial element is the sealing system; resilient strips, usually made of materials like graphite or specialized plastics, press against the inner surface of the rotating shell, creating a seal around the vacuum box. This seal isolates the vacuum zone from the atmospheric pressure outside the box, allowing the vacuum to effectively pull water through the web and shell. Without effective sealing, vacuum levels drop dramatically, rendering the roll inefficient. The design of these vacuum boxes, including their width and placement, is tailored to the specific paper grade and machine speed to optimize the dewatering profile and prevent issues like streaking or overdrying in certain areas. It's worth noting that the integrity of these internal components is paramount for sustained high performance.

Critical Impact on Paper Quality and Machine Performance

The performance of the suction couch roll has profound implications that ripple throughout the entire paper machine and significantly influence the final product. Firstly, effective dewatering at this stage increases the sheet's dry content (consistency) before it enters the press section. A higher incoming consistency means the presses can achieve higher dewatering rates, further reducing the load on the dryer section. This chain reaction translates directly into the ability to run the machine faster, increasing throughput and production capacity. Secondly, removing water uniformly helps create a more consistent moisture profile across the sheet width, which is essential for preventing sheet curling, wrinkling, and other quality defects. Thirdly, the gentle vacuum action helps consolidate the newly formed web, imparting initial wet strength and reducing the likelihood of web breaks, particularly important at the couch roll where the web transitions from the relatively unsupported wire section to the felted press section. Have you ever experienced frequent web breaks at high speeds? Often, the root cause can be traced back to inadequate or uneven dewatering at the couch. Improving this critical step directly enhances machine runnability and uptime.

Enhancing Sheet Strength and Reducing Web Breaks

Let's elaborate on the crucial aspect of sheet strength and break reduction, which is a major benefit derived from an effectively operating suction couch roll. As the paper web passes over the vacuum zone, the pressure difference not only removes water but also helps to compact the fiber structure slightly. This mild consolidation, combined with the removal of excess water, gives the nascent sheet just enough integrity to withstand the stresses it will encounter as it moves through the machine. Think of it like gently firming up a wet sponge – it becomes less prone to tearing when handled. In high-speed paper making, where web tension is significant, any weakness or discontinuity in the sheet can lead to a devastating break, causing costly downtime and lost production. A well-designed and maintained suction couch roll minimizes this risk by ensuring the sheet leaving the couch has sufficient strength and uniformity. In my experience, investing in optimal suction couch roll technology and maintenance often pays dividends through reduced breaks and increased overall efficiency, allowing operators to push machine speeds higher with greater confidence.

Design Considerations and Technological Advancements

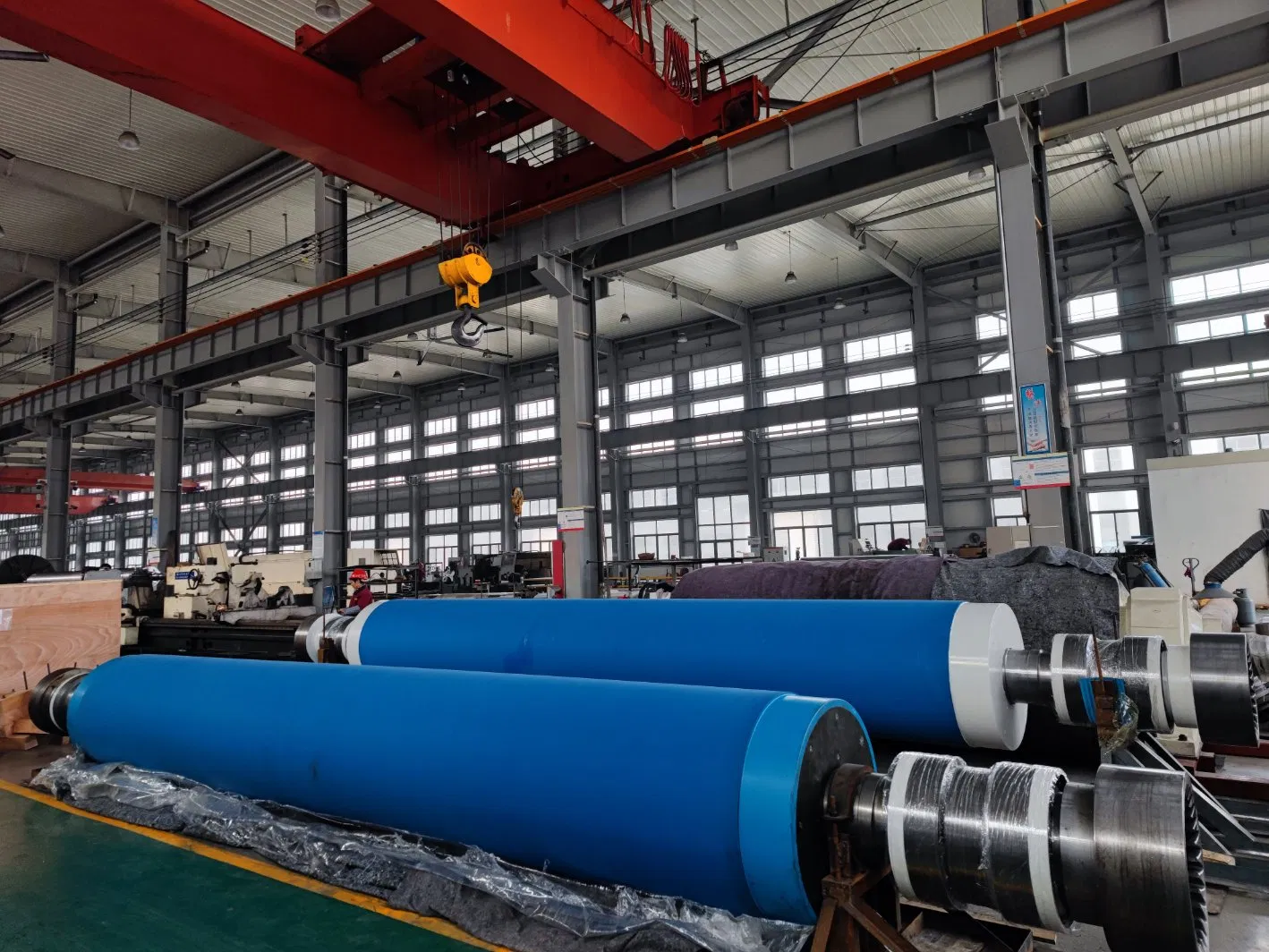

Modern suction couch rolls are sophisticated pieces of engineering, incorporating various design features and materials to meet the demands of high-speed, high-volume paper production. Shell construction materials range from bronze and stainless steel alloys to composite materials, chosen for their strength, corrosion resistance, and weight characteristics. The pattern, size, and depth of the drilled holes are carefully calculated to optimize vacuum levels and water removal for specific paper grades and machine speeds. Bearing systems, often self-aligning, must withstand heavy loads and operate reliably in a wet, demanding environment. Sealing strip materials and designs have evolved significantly, offering improved sealing efficiency and reduced wear on the shell. Interestingly enough, some advanced designs incorporate features like variable vacuum control across the width or length of the roll to fine-tune dewatering profiles and correct moisture variations. These technological advancements in suction couch roll paper machine design aim to maximize water removal efficiency, minimize energy consumption, and extend the operational life of the roll between maintenance cycles. Choosing the right design for a specific application is a critical technical decision.

Maintaining Peak Performance: Common Issues and Solutions

Even the most advanced suction couch roll requires diligent maintenance to sustain peak performance over its lifespan. Common issues include shell wear, often due to abrasive fillers or inadequate lubrication of the sealing strips; bearing failure due to moisture or load; and problems with the vacuum system, such as clogged perforations, worn seals, or issues with the vacuum pump itself. Vibration can also be a significant problem, potentially caused by uneven shell wear, imbalance, or issues with supporting structures. Addressing these issues proactively is key. Regular inspections, cleaning of shell perforations (often using high-pressure showers), lubrication, and timely replacement of worn sealing strips are fundamental maintenance practices. Monitoring vacuum levels, energy consumption of the vacuum pumps, and the roll's vibration signature can provide early warnings of developing problems. Frankly speaking, neglecting maintenance on a suction couch roll can lead to a cascade of issues affecting machine stability and paper quality. Identifying and resolving these problems promptly is crucial for maximizing uptime and efficiency. Many experts agree that a robust preventative maintenance program is non-negotiable for these critical rolls.

Troubleshooting and Optimizing Dewatering

When a suction couch roll isn't performing optimally, troubleshooting requires a systematic approach. Is there a loss of vacuum? This could indicate worn seals, a problem with the vacuum pump, or excessive air leakage. Is the dewatering uneven across the web? This might point to clogged holes in specific areas of the shell, uneven wear patterns, or improperly adjusted vacuum boxes or sealing strips. Is there excessive vibration? This could be an issue with balance, bearings, or possibly structural issues. Diagnosing these problems often involves process monitoring (vacuum levels, power consumption), physical inspection of the roll and its components, and sometimes specialized diagnostic tools like vibration analysis or thermal imaging. Identifying the root cause is the first step; the next is implementing the correct solution, whether it's cleaning, adjustment, repair, or replacement. Optimizing dewatering goes beyond just fixing problems; it involves continuously evaluating performance against production goals and making fine-tuning adjustments to vacuum levels, shower pressures, and potentially considering upgrades if the current technology is limiting performance. Why is this approach so effective? Because it moves from reactive fixing to proactive improvement, driving efficiency gains.

Selecting the Ideal Suction Couch Roll for Your Needs

Choosing the right suction couch roll paper machine components or a replacement roll is a significant decision that impacts machine performance and operational costs for years to come. The ideal roll design depends on several factors, including the type and grade of paper being produced, the machine speed, the available vacuum system capacity, the desired sheet consistency targets, and specific operational constraints like space and maintenance access. Considerations include the material and drilling pattern of the shell, the design and sealing efficiency of the internal vacuum system, the type of bearing system, and the overall build quality. A careful analysis of your specific paper making process and requirements is essential. Sometimes, upgrading to a roll with more advanced features, like improved sealing or a different drilling pattern, can yield significant improvements in dewatering efficiency and machine speed. Partnering with suppliers who possess deep expertise in paper machine rolls and dewatering technology is invaluable during this selection process, ensuring you invest in a solution that truly meets your operational needs and contributes to your overall production goals. Their experience can help navigate the options and identify the most suitable technology.

Partnering for Suction Couch Roll Excellence

Ultimately, achieving and maintaining excellence in the performance of your suction couch roll paper machine requires more than just having the right hardware; it demands expertise, timely maintenance, and sometimes, access to specialized services or replacement parts. Given the critical nature of this component and its impact on energy consumption, machine speed, and product quality, ensuring its reliability is paramount. Whether you are dealing with routine maintenance, troubleshooting a performance issue, considering an upgrade, or needing a complete replacement roll, having a reliable partner with in-depth knowledge of suction couch roll technology can make a world of difference. Such a partner can offer insights into optimal operating parameters, provide expert advice on maintenance best practices, assist with diagnostics, and supply high-quality components designed for longevity and performance. Investing in the health of your suction couch roll is investing in the efficiency and profitability of your entire paper machine operation. Don't underestimate the impact this single roll can have on your bottom line.

In conclusion, the suction couch roll paper machine is a cornerstone of effective dewatering in paper production. Its proper function is inextricably linked to machine speed, energy efficiency, and paper quality. Understanding its principles, design nuances, and maintenance requirements is key to optimizing paper machine performance. From the intricate vacuum system within the shell to its profound effect on downstream processes, mastering the suction couch roll is a vital step towards achieving world-class paper production. Ensure your couch roll is operating at its best through proper selection, diligent maintenance, and expert support. For more detailed information, please visit our official website: suction couch roll