Boosting efficiency is the lifeblood of any successful industrial operation, and perhaps nowhere is this more critical than within a bustling paper mill. The complex machinery, the continuous production lines, the sheer scale of output demanded – it all hinges on seamless, high-performance processes. At the heart of this intricate dance of fibers, water, and chemicals lie components that often work tirelessly behind the scenes: the paper mill rolls. These aren't just simple cylinders; they are precision-engineered parts subjected to immense pressures, varying temperatures, and constant friction. Their condition, their material, their design – every aspect plays a monumental role in determining how smoothly and how quickly paper is produced. Frankly speaking, the difference between a good roll and a top-tier roll can translate directly into significant gains in throughput, reductions in waste, and overall operational efficiency. This guide aims to delve deep into how leveraging top paper mill rolls isn't just an operational choice, but a strategic imperative for any mill looking to optimize its performance and stay competitive in a demanding market. We'll explore the multifaceted ways these critical components contribute to boosting efficiency and what constitutes a "top" roll in this challenging environment.

Understanding How Paper Mill Rolls Directly Impact Efficiency

It seems straightforward, right? A roll turns, and paper moves. But the reality is far more complex, and the impact of paper mill rolls on operational efficiency is profound and far-reaching. Think about the various stages of paper production: forming, pressing, drying, calendering, reeling, and converting. Each of these stages relies heavily on specific types of rolls, each designed to perform a unique task under demanding conditions. In the press section, for instance, rolls are crucial for dewatering the paper web. The pressure applied, the surface properties of the rolls, and their ability to maintain uniform nip pressure directly affect how much water is removed. Inefficient dewatering here means more energy needed later in the drying section, a massive energy consumer. So, an underperforming press roll doesn't just slow things down; it significantly increases energy costs and bottlenecks the entire drying process. Similarly, in the drying section, dryer rolls transfer heat to the paper, and their surface condition and internal heating efficiency determine how quickly and evenly the paper dries. A roll with poor heat transfer capabilities or a damaged surface can lead to uneven drying, quality issues, and slower machine speeds. Interestingly enough, even seemingly simple rolls like idler rolls or guide rolls play a vital role in web handling, preventing breaks and ensuring smooth travel, which are absolutely essential for continuous, efficient operation. Any issue with a roll – wear, damage, improper coating, imbalance – can cascade through the process, causing slowdowns, defects, and costly downtime. This intricate dependency underscores why focusing on the quality and performance of these rolls is fundamental to boosting overall mill efficiency.

Identifying the Characteristics of Top Paper Mill Rolls for Peak Performance

What exactly elevates a standard paper mill roll to the status of "top"? It's a combination of factors centered around material science, precision engineering, and application-specific design. To be honest, there isn't a single magic bullet; rather, it's the synergy of several key characteristics. First and foremost is the material. Top rolls are often constructed from advanced alloys or composites chosen for their specific properties: high strength-to-weight ratio, excellent corrosion resistance, superior wear resistance, and the ability to withstand extreme temperatures and pressures. The surface coating is equally critical. Whether it's a specialized ceramic, polymer, or metallic coating, it must provide the required grip or slip, resist buildup, and maintain its integrity under harsh operating conditions for extended periods. A top-quality coating can drastically reduce wear on both the roll and the paper web, minimize fiber adhesion, and improve dewatering or heat transfer efficiency depending on the application. Precision is non-negotiable. Top rolls boast extremely tight tolerances for diameter, straightness, and runout. Any eccentricity or imbalance can lead to vibrations, uneven pressure distribution, and web handling issues, all of which severely detract from efficiency and paper quality. Furthermore, features like optimized internal cooling or heating passages, advanced bearing systems, and robust shell designs contribute to their longevity and consistent performance. A truly top roll is engineered not just to perform its basic function, but to do so reliably, durably, and with minimal energy loss or negative impact on the process, allowing the machine to run at its optimal speed and capacity.

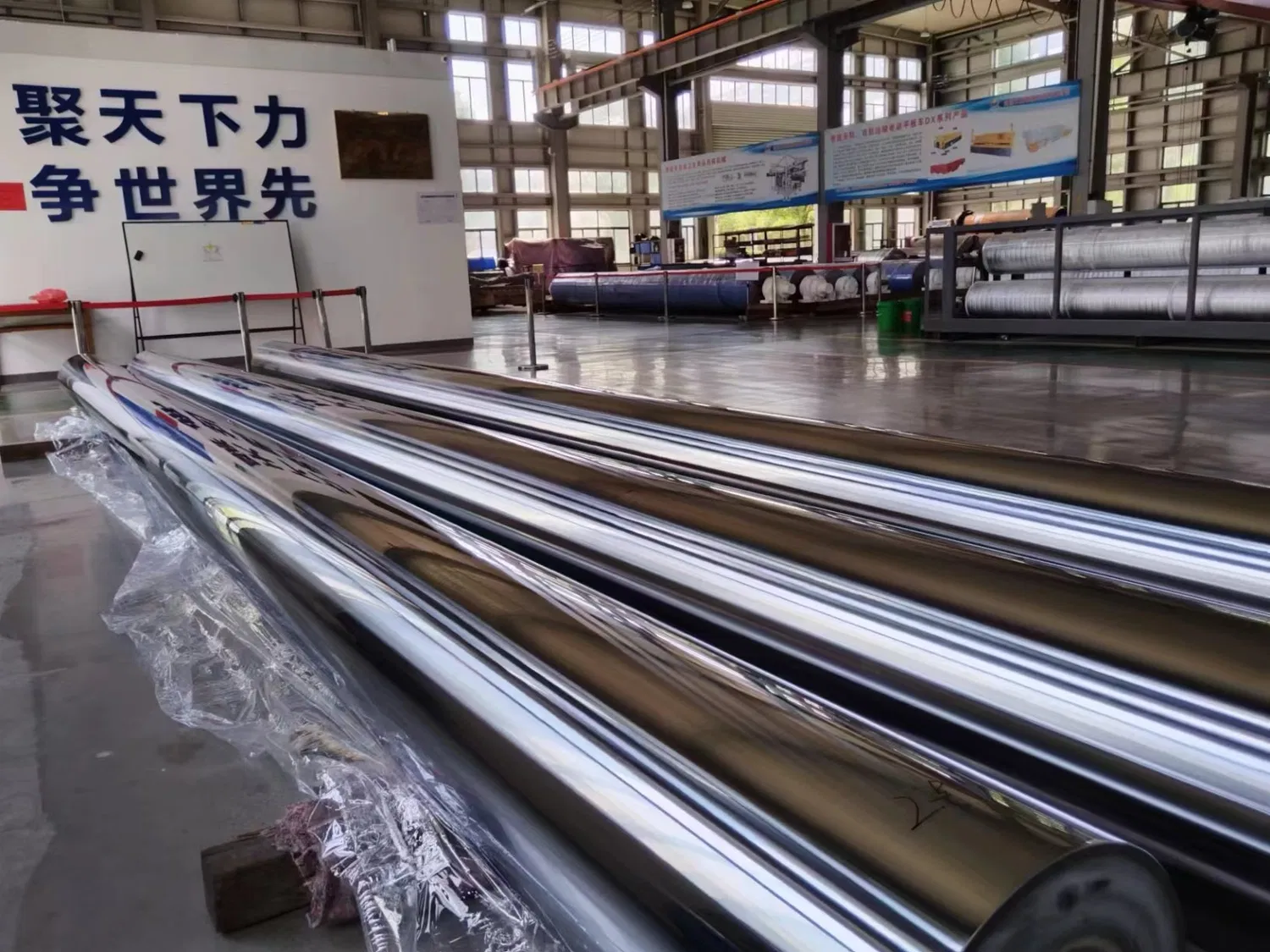

Advanced Materials and Coatings: The Foundation of Longevity and Performance

Delving deeper into what makes a roll "top," the choices of materials and surface treatments are paramount. In many demanding positions, traditional materials might simply not hold up to the aggressive chemical environments, high temperatures, or abrasive conditions. This is where advanced materials come into play. High-strength steel alloys with specific heat treatments offer enhanced mechanical properties and resistance to fatigue. For rolls operating in corrosive areas, stainless steel or even more exotic alloys might be used, potentially clad or overlaid for maximum protection. Carbon fiber composites are increasingly being utilized, particularly for rolls requiring high stiffness, low weight, and excellent vibration damping characteristics. Their lighter weight can also reduce energy consumption and bearing load. When it comes to coatings, the options are vast and tailored to the roll's function. Hard chrome was a long-standing standard, but newer thermal spray coatings, such as ceramics (e.g., chromium oxide, tungsten carbide) or specialized polymers, offer vastly improved wear resistance, release properties, and chemical inertness. For press rolls, elastomeric covers have seen significant advancements, providing specific hardness profiles, improved dewatering channels, and enhanced durability. The science behind selecting the right material and coating for each roll position is complex, involving careful consideration of operational parameters, chemical exposure, mechanical loads, and desired surface properties. Investing in rolls featuring these advanced materials and coatings might represent a higher initial cost, but the extended lifespan, reduced maintenance needs, and significant improvements in efficiency and paper quality offer a compelling return on investment. Have you ever considered the specific wear mechanisms affecting your most problematic rolls? Understanding these mechanisms is the first step in selecting a material or coating that can dramatically improve performance and lifespan.

A Complete Guide to Selecting the Right Rolls for Maximum Efficiency

Selecting the right paper mill rolls is far from a one-size-fits-all scenario. It requires a systematic approach, akin to a complete guide, considering the specific demands of each position within the paper machine. Simply replacing a worn roll with the exact same type might be a missed opportunity to boost efficiency. The selection process should begin with a thorough analysis of the current roll's performance history, including its lifespan, failure modes (wear, corrosion, cracking, cover issues), and its impact on machine speed, paper quality, and energy consumption. What are the specific operational parameters for that roll? This includes line speed, temperature, pressure, chemical environment (pH, concentration of additives), and the type of paper being produced. Different paper grades and processes place unique stresses on rolls. For example, producing abrasive grades or using aggressive bleaching chemicals requires rolls with superior corrosion and wear resistance. The desired function of the roll is obviously key – dewatering, heat transfer, web support, calendering, etc. Each function necessitates specific surface properties, internal construction, and material choices. Working with experienced suppliers who understand these nuances is invaluable. They can provide insights into the latest material advancements, coating technologies, and design optimizations that are tailored to your mill's specific challenges. It's not just about buying a roll; it's about procuring a solution that is optimized for its role in boosting your mill's overall efficiency. This involves understanding not just the roll itself, but its interaction with the paper web and the surrounding machinery.

Maintenance and Care: Sustaining Top Roll Performance Over Time

Having the best paper mill rolls is only half the battle; sustaining their top performance over time is crucial for long-term efficiency gains. A complete guide to leveraging top rolls must include robust maintenance practices. Rolls are subject to wear and tear, and neglecting their care can quickly degrade their performance, leading to the very inefficiencies you sought to eliminate. Regular inspection is fundamental. This isn't just looking for obvious damage; it involves using precision tools to check for uniform wear, surface defects, signs of corrosion, and changes in profile or diameter. Non-destructive testing methods can reveal internal flaws or coating delamination before they cause catastrophic failure. Cleaning is another vital aspect. Proper cleaning prevents buildup of stock, chemicals, and contaminants that can affect surface properties, lead to uneven wear, and compromise paper quality. The cleaning method and frequency must be appropriate for the roll material and coating. Grinding and resurfacing are often necessary over the roll's lifespan to restore its desired profile and surface finish. This requires specialized equipment and expertise to ensure the work is done to tight tolerances, preserving the roll's balance and performance characteristics. Lubrication of bearings and seals according to manufacturer recommendations is also critical to prevent premature failure. Proactive, condition-based monitoring, using sensors to track temperature, vibration, and load, can provide early warnings of potential issues, allowing for planned maintenance rather than reactive repairs. Investing in a comprehensive roll maintenance program ensures that your top-tier rolls continue to deliver the efficiency benefits they were designed for throughout their operational life.

Troubleshooting Common Roll Issues and Their Impact on Efficiency

Even top paper mill rolls can encounter issues, and recognizing these problems early and understanding their impact on efficiency is key to quick resolution. Common issues include uneven wear, which leads to non-uniform nip pressure in press or calender rolls, resulting in variations in moisture content or caliper across the web, impacting quality and potentially slowing the machine. Corrosive damage can weaken the roll structure, compromise coatings, and lead to surface pitting, all of which disrupt the smooth interaction with the paper web and reduce roll lifespan. Cover delamination on covered rolls, particularly in press sections, can cause significant web breaks and unplanned downtime. Bearing failures are a major culprit for unexpected shutdowns, resulting from poor lubrication, contamination, or excessive load. Vibrations, often caused by roll imbalance or bearing issues, not only affect roll and machine health but also impact paper quality and limit operating speed. Stock buildup on roll surfaces is another frequent problem, altering surface properties, causing picking, and potentially leading to web breaks. Each of these issues, if left unaddressed, directly erodes operational efficiency. A roll operating with uneven wear requires the machine to run slower to maintain quality, reducing throughput. A corroded roll may need premature replacement, incurring costs and downtime. Understanding the root cause of these problems – be it improper roll selection, inadequate maintenance, or process variations – is crucial for effective troubleshooting and preventing recurrence. It's worth noting that seemingly minor issues with a roll can have disproportionate effects on the overall efficiency of the high-speed paper machine.

The Economic Advantages of Investing in Top-Tier Paper Mill Rolls

While top paper mill rolls may come with a higher initial purchase price compared to standard options, the economic advantages they offer in terms of boosting efficiency are compelling and typically deliver a strong return on investment over their lifespan. The most immediate economic benefit comes from reduced downtime. Top rolls are designed for durability and reliability; their robust construction, advanced materials, and superior coatings mean they are less prone to premature failure than lower-quality alternatives. Every hour of unscheduled downtime in a paper mill is incredibly costly in terms of lost production, wasted materials, and labor. By minimizing unplanned stops related to roll issues, top rolls contribute directly to higher machine availability and increased output. Furthermore, their superior performance characteristics – whether it's more efficient dewatering in the press section, improved heat transfer in drying, or more consistent calendering – allow the machine to run at higher speeds while maintaining or improving paper quality. This increase in throughput translates directly into higher production volume within the same operating hours. Reduced energy consumption is another significant economic advantage. Efficient dewatering reduces the energy load on dryers, and well-maintained, properly balanced rolls require less power to turn. The extended lifespan of top rolls also means lower replacement frequency, saving not only the cost of new rolls but also the labor and downtime associated with roll changes. When you factor in reduced waste from fewer web breaks and improved quality, the total cost of ownership for top-tier rolls is often significantly lower than that of cheaper alternatives. It’s a clear case where paying more upfront for quality components pays dividends in the long run through operational savings and increased revenue potential.

In conclusion, boosting efficiency in a paper mill is a complex undertaking involving numerous factors, but the critical role played by paper mill rolls cannot be overstated. As this complete guide has highlighted, transitioning from standard rolls to top-tier ones, combined with diligent maintenance, is a powerful strategy for achieving significant improvements. From enabling higher machine speeds through precision and balance, to reducing energy consumption via efficient dewatering and drying, to minimizing costly downtime through enhanced durability and reliability, top paper mill rolls are instrumental in optimizing every stage of the paper production process. Identifying what constitutes a "top" roll involves understanding the importance of advanced materials, application-specific coatings, and meticulous engineering tolerances. Sustaining their performance requires a commitment to proactive maintenance, including regular inspection, cleaning, and precision grinding. While the initial investment might be higher, the long-term economic benefits derived from increased throughput, reduced waste, lower energy costs, and fewer unplanned stops make a compelling case for prioritizing the selection and care of these vital components. By leveraging the insights and practices outlined in this guide, paper mills can unlock the full potential of their machinery, achieving peak performance and greater profitability. Do you have a clear strategy for evaluating the total cost of ownership for your mill rolls, considering not just purchase price but also maintenance and impact on efficiency?

For more detailed information, please visit our official website: paper mill rolls