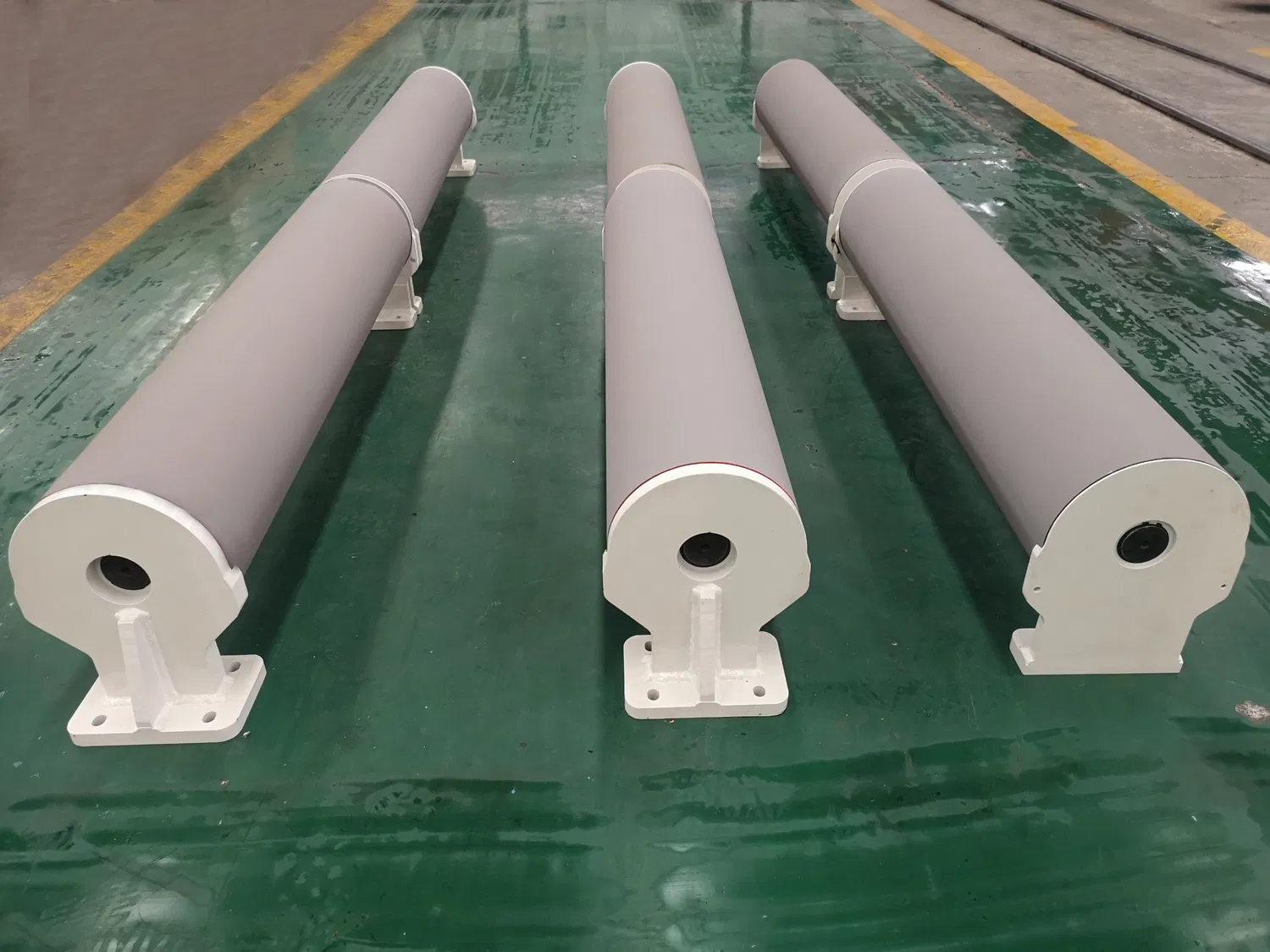

In the intricate world of manufacturing and industrial processes, rolls are often the unsung heroes, quietly facilitating everything from printing and packaging to steel production and textile finishing. These cylindrical components are critical for transporting materials, applying pressure, transferring inks or adhesives, and ensuring precise control over webs and sheets. However, the demanding environments they operate in—characterized by constant friction, abrasive materials, corrosive chemicals, and fluctuating temperatures—can quickly degrade their surfaces, leading to reduced efficiency, compromised product quality, and costly downtime. This is where the vital field of roll coatings comes into play. Understanding roll coatings isn't just about knowing what they are; it's about appreciating their transformative power in enhancing the performance and significantly extending the durability of these essential industrial assets. It's a complex interplay of material science, application technology, and process engineering, all aimed at pushing the boundaries of what a simple roll can achieve.

Think about the sheer variety of tasks rolls perform across different industries. A roll in a paper mill might be subjected to high moisture, heat, and abrasive pulp fibers. In a printing press, rolls need extremely precise surface finishes and specific ink-release properties. Steel mill rolls endure immense pressure and high temperatures, while textile rolls might require coatings that prevent sticking or static buildup. Without specialized surface treatments, the base material of the roll—be it steel, aluminum, or composite—would rapidly wear down, corrode, or simply fail to provide the necessary functional characteristics for the process. This inherent vulnerability highlights the necessity of applying a protective or functional layer. Coatings act as a sacrificial shield or provide a completely new surface interface, engineered to withstand the specific stresses of the application. To be honest, selecting the right coating is rarely a simple task; it requires a deep dive into the operational parameters and the desired outcome, whether that's improved grip, reduced friction, enhanced chemical resistance, or superior wear life. It’s this targeted modification of the roll surface that unlocks substantial improvements in operational efficiency and longevity.

Understanding the Fundamental Role of Roll Coatings

At its core, understanding roll coatings means recognizing that they are not merely paint or a thin film applied for aesthetic purposes. Instead, they are carefully engineered surface layers, often microns to millimeters thick, designed to impart specific physical, chemical, or mechanical properties to the roll's surface that the base material alone cannot provide. The primary role is to modify the interaction between the roll surface and the material or environment it contacts. This could involve creating a surface that is incredibly hard and wear-resistant, surprisingly smooth and non-stick, electrically conductive or insulative, or even resistant to aggressive chemicals or extreme temperatures. This fundamental modification is precisely how coatings contribute to both performance and durability. By changing the surface characteristics, the roll can perform its function more effectively and for a much longer duration before requiring maintenance or replacement. It's a sophisticated way of tailoring the roll's interaction with its operational surroundings, directly addressing the limitations of the underlying substrate and unlocking new levels of efficiency and reliability in demanding applications.

Interestingly enough, the 'understanding' aspect extends beyond just the coating material itself to the critical interface between the coating and the substrate. A coating is only as good as its adhesion to the roll base. Poor surface preparation or an incompatible coating-substrate pairing can lead to delamination, cracking, or premature failure, negating any potential performance or durability benefits. Therefore, a comprehensive understanding includes the preparatory steps—cleaning, grit blasting, bonding layers—that ensure the coating forms a robust, integral part of the roll structure. Many experts agree that overlooking these crucial initial steps is a common pitfall. Furthermore, the internal structure of the coating itself, its porosity, hardness profile, and residual stresses, all play a significant role in its ultimate success. It’s a complex ecosystem of materials science where every layer and every process step contributes to the final functional outcome, directly impacting how well the roll performs and how long it lasts under strenuous conditions. This holistic view is essential for anyone involved in specifying, applying, or maintaining industrial rolls.

How Roll Coatings Directly Enhance Industrial Performance

When we talk about enhancing performance through roll coatings, we're referring to optimizing the roll's functional behavior within a specific process. One of the most common performance enhancements is controlling the coefficient of friction. Coatings can be applied to create a high-friction surface for gripping and driving webs without slippage, essential in textile or paper handling. Conversely, a coating might be designed to be extremely low-friction, facilitating easy release of sticky materials like adhesives or certain plastics, crucial in packaging or food processing. Beyond friction, surface energy plays a key role; low surface energy coatings promote non-stick properties, preventing material buildup and ensuring clean separation, which directly improves product quality and reduces cleaning cycles. Imagine a printing roll where ink doesn't release cleanly – the print quality would be disastrous. A carefully chosen coating solves this. Furthermore, coatings can provide specific surface textures, from highly polished finishes that produce a smooth, glossy product surface to rougher textures that facilitate uniform spreading of liquids or powders. These tailored surface properties are not incidental; they are engineered to meet the precise functional requirements of the manufacturing process, directly contributing to higher speeds, greater precision, and improved output quality. Have you ever wondered how different materials can be processed so efficiently? Often, the secret lies in the roll surface.

Beyond surface mechanics, coatings can also impart performance characteristics related to conductivity or thermal management. In processes where static electricity is a problem, such as film handling or powder coating, conductive or anti-static coatings can dissipate charge buildup, preventing sparks, material clumping, and potential hazards. Conversely, insulative coatings might be needed in electrical manufacturing or specific chemical processes to prevent current flow. Thermal performance is another critical area. Some coatings can enhance heat transfer, useful in drying or curing processes, while others can act as thermal barriers, protecting the underlying roll from extreme temperatures. The ability to control these properties allows rolls to operate effectively in environments that would otherwise be impossible or highly inefficient. For instance, rolls in high-temperature furnaces or ovens rely heavily on thermal barrier coatings to maintain their structural integrity and function. This ability to customize the roll's interaction with its environment, whether mechanical, electrical, or thermal, fundamentally enhances its operational performance, enabling processes to run faster, more reliably, and with better results. It's fascinating how a relatively thin layer can completely change how a heavy piece of machinery behaves.

Roll Coatings: A Key Factor in Improving Durability and Lifespan

While enhancing performance is crucial for immediate operational efficiency, improving durability is vital for long-term economic viability and reliability. Coatings play a fundamental role in protecting the base roll material from the various forms of degradation encountered in harsh industrial settings. Wear is arguably the most common challenge. Abrasive materials constantly moving over the roll surface can rapidly erode softer substrates. Hard coatings, such as ceramics, carbides, or hard chrome plating, offer significantly higher resistance to abrasion and erosion, allowing the roll to maintain its dimensions and surface finish for extended periods. Frankly speaking, without such protection, rolls in applications like abrasive paper handling or bulk material transport would wear out alarmingly quickly, necessitating frequent and costly replacements. This wear resistance translates directly into reduced downtime, lower maintenance costs, and a predictable operational life for the roll. The increased lifespan is not just a convenience; it's a major contributor to the overall profitability of a manufacturing operation, allowing for longer production runs and minimizing interruptions.

Corrosion and chemical attack are equally significant threats to roll durability, particularly in industries involving wet processes or exposure to aggressive chemicals. Base metals like steel can rust in humid environments or be dissolved by acids, alkalis, or solvents. Coatings act as impermeable barriers, preventing corrosive substances from reaching the substrate. Materials like polymers, ceramics, or certain metallic alloys are inherently resistant to a wide range of chemicals and environments. Applying a suitable coating can allow a standard steel roll to operate reliably in conditions that would otherwise quickly destroy it. Consider the chemical processing industry or pulp and paper manufacturing, where rolls are constantly exposed to corrosive media. A well-chosen coating ensures the roll maintains its structural integrity and surface functionality, preventing costly failures and environmental hazards associated with material degradation. Furthermore, coatings can offer protection against impact damage or cavitation, where rapid pressure changes can erode the surface. This multi-faceted protection is what makes coatings indispensable for ensuring the long-term durability and reliability of industrial rolls under challenging conditions.

Exploring Different Roll Coating Technologies

Understanding roll coatings also means delving into the diverse array of technologies used to apply them, as each method offers unique advantages and is suited to different materials, thicknesses, and application requirements, all contributing to the desired performance and durability outcomes. Thermal spray processes, such as High-Velocity Oxygen Fuel (HVOF), plasma spray, or wire arc spray, are versatile methods capable of depositing a wide range of metallic, ceramic, and cermet materials. These coatings are known for their high hardness, wear resistance, and ability to build up thicker layers, making them excellent choices for combating abrasion, erosion, and corrosion. Plating, particularly hard chrome plating, has been a traditional method for providing wear resistance and a smooth, hard surface, although its use is facing increasing environmental scrutiny. Electroless nickel plating offers uniform coating thickness on complex shapes and can provide good corrosion and wear resistance, often enhanced by co-depositing particles like PTFE or silicon carbide for added performance benefits.

Polymer and rubber coatings represent another major category, offering flexibility, release properties, chemical resistance, and grip. Rubber coatings are widely used in printing, textiles, and material handling for their conformability and traction. Polymer coatings, like fluoropolymers (e.g., PTFE) or polyurethanes, provide excellent non-stick properties, chemical inertness, and corrosion resistance, often applied via rotational lining, spraying, or powder coating techniques. Ceramic coatings, sometimes applied via PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) for thinner, extremely hard layers, or as thicker thermal spray coatings, provide exceptional hardness, wear resistance, and thermal insulation. Each technology has its sweet spot based on the required coating material, desired thickness, surface finish, and the specific performance or durability challenge being addressed. Selecting the optimal technology is as critical as choosing the right material, and often, successful application relies heavily on the expertise and equipment available. In my experience, the interplay between material science and application method is absolutely key to achieving the desired enhancement in performance and durability.

Selecting the Optimal Roll Coating for Specific Needs

With such a vast array of materials and application methods available, the process of selecting the optimal roll coating can feel daunting, yet it is absolutely critical for achieving the intended performance enhancement and durability improvements. The selection process must begin with a thorough analysis of the operating environment and the specific functional requirements of the roll. What materials will the roll contact? What are the operating temperatures and pressures? Are corrosive chemicals present? What level of wear or abrasion is expected? What surface finish or friction characteristics are needed? Answering these questions provides a clear set of criteria for evaluating potential coating options. The substrate material of the roll is also a major consideration, as the coating must be compatible and adhere properly. Some coatings are only suitable for specific metals, while others can be applied to ceramics or composites. Understanding these constraints is fundamental to making a sound choice. Factors like coating thickness, hardness, elasticity, thermal conductivity, and surface energy all need to be matched to the application demands.

Cost is, of course, always a factor, but it's essential to consider the total cost of ownership rather than just the initial application price. A more expensive, higher-performing coating that lasts significantly longer and reduces downtime can offer a much better return on investment than a cheaper coating that wears out quickly or fails to provide the required performance. Lead time for application and refurbishment is another practical consideration that impacts operational planning. Furthermore, environmental regulations may influence coating choices, particularly concerning materials like hard chrome plating. This is where partnering with a knowledgeable provider becomes invaluable. Our company specializes in helping manufacturers navigate these complex decisions. We work closely with clients to analyze their specific operational challenges and recommend coating solutions that are precisely tailored to enhance the required performance characteristics and maximize the durability of their rolls. It's about leveraging our expertise in material science and application technologies to provide a solution that delivers tangible improvements in efficiency and lifespan, ensuring the coating isn't just applied, but is the *right* coating for the job.

The Impact of Proper Application on Roll Coating Effectiveness

It's one thing to select the perfect coating material and technology based on theoretical understanding; it's another entirely to ensure it is applied correctly to achieve the intended performance and durability benefits. The application process itself is incredibly critical. Proper surface preparation of the roll is paramount. This typically involves thorough cleaning to remove grease, oils, and debris, followed by mechanical preparation like grit blasting to create a surface profile that promotes excellent mechanical keying and adhesion of the coating. If the surface isn't prepared correctly, even the most advanced coating will fail prematurely, peeling or delaminating under stress. The application parameters—such as temperature, pressure, spray distance, or plating bath chemistry—must be meticulously controlled according to established procedures for the chosen coating technology. Deviations can lead to porosity, internal stresses, incorrect thickness, or suboptimal microstructures within the coating, all of which compromise its protective and functional properties.

Quality control throughout and after the application process is non-negotiable. Techniques like visual inspection, thickness measurement, hardness testing, adhesion testing (e.g., pull-off tests), and even microstructural analysis are employed to verify that the coating meets the required specifications. A coating that looks fine on the surface might have hidden flaws that will drastically reduce its lifespan or prevent it from delivering the expected performance. For instance, insufficient hardness means it won't resist wear as intended, while poor adhesion means it could suddenly fail in service. Ensuring consistency from batch to batch is also vital for predictable roll performance and maintenance planning. This rigorous attention to detail during application and quality assurance is what separates a good coating from a substandard one and directly impacts how effectively the coating enhances the roll's performance and durability in the real world. It truly underscores that the success of a roll coating is a combination of the right material, the right application technology, and meticulous execution.

Understanding roll coatings is a continuous process, adapting to new materials, technologies, and industrial demands. The pursuit of enhanced performance and greater durability is an ongoing challenge in manufacturing, driving innovation in surface engineering. As materials and processes become more demanding, the role of sophisticated roll coatings becomes even more critical. They enable industries to operate at higher speeds, handle more aggressive substances, and achieve tighter tolerances, all while extending the life of valuable assets. The insights gained from understanding the various coating types, their benefits, application methods, and the crucial selection criteria empower businesses to make informed decisions that directly impact their bottom line through reduced maintenance, minimized downtime, and improved product quality. It's a field that blends fundamental science with practical application, constantly evolving to meet the challenges of modern manufacturing. What future challenges in your industry could be solved with advanced roll coatings?

In conclusion, understanding roll coatings is fundamental to unlocking the full potential of industrial rolls. As we've explored, these engineered surfaces are far more than mere protective layers; they are transformative elements capable of dramatically enhancing performance characteristics like friction, release, conductivity, and thermal properties, while simultaneously boosting durability by providing exceptional resistance to wear, corrosion, chemical attack, and impact. The selection of the appropriate coating material and application technology, coupled with meticulous execution and quality control, is paramount to realizing these benefits. By carefully considering the specific operational environment and desired outcomes, manufacturers can leverage the power of roll coatings to improve efficiency, reduce operating costs, and significantly extend the service life of critical equipment. Embracing a comprehensive understanding of this technology is a strategic investment in the reliability and competitiveness of industrial operations. For detailed information on how tailored roll coating solutions can address your specific performance and durability needs, we invite you to learn more.

For more detailed information, please visit our official website: Roll Coatings