In the dynamic world of paper production, especially within the realm of recycled paper manufacturing, the efficiency and reliability of machinery are paramount. Producing high-quality paper from recycled fibers presents unique challenges, including managing web stability, preventing wrinkles, and ensuring consistent sheet formation. Every component within the complex paper machine plays a critical role in overcoming these hurdles. Among the many essential spare parts, the Bow Curved Roll stands out as a deceptively simple yet profoundly impactful element. Often referred to as a bowed roll or spreader roll, its unique curved shape is specifically engineered to interact with the paper web, providing crucial support and control at various stages of the process. For manufacturers relying on recycled stock, selecting the right Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) is not just about replacement; it's about investing in the core performance and output quality of their production line. A well-designed and precisely manufactured bowed roll can significantly enhance paper properties, reduce downtime, and contribute to the overall profitability of the mill. Understanding the technical nuances and operational benefits of this vital component is key to maintaining optimal production levels.

Understanding the Critical Function of the Bowed Roll in Recycled Paper Production

The role of the Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) is fundamentally linked to managing the paper web's width and tension as it travels through the machine. Recycled pulp, with its varying fiber lengths and potential contaminants, can be particularly prone to issues like web shrinkage, wrinkling, and uneven moisture profiles. This is where the strategic placement and design of a bowed roll become indispensable. Positioned at critical points, such as before or after dryer sections, calenders, or winders, the convex shape of the roll gently stretches the web outward from the center towards the edges. This spreading action is crucial for preventing creases and ensuring a smooth, flat sheet. Furthermore, by controlling the tension and ensuring full-width contact with subsequent rolls or cylinders, the bowed roll helps maintain web stability, significantly reducing the risk of breaks. In the demanding environment of recycled paper making, where uptime is critical and quality must be consistent despite raw material variability, the reliable performance of every Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) is non-negotiable. Its ability to handle moisture variations, fiber clumping, and the inherent tensions within the web directly impacts the final product's quality and the machine's operational efficiency.

Technical Specifications and Design Excellence

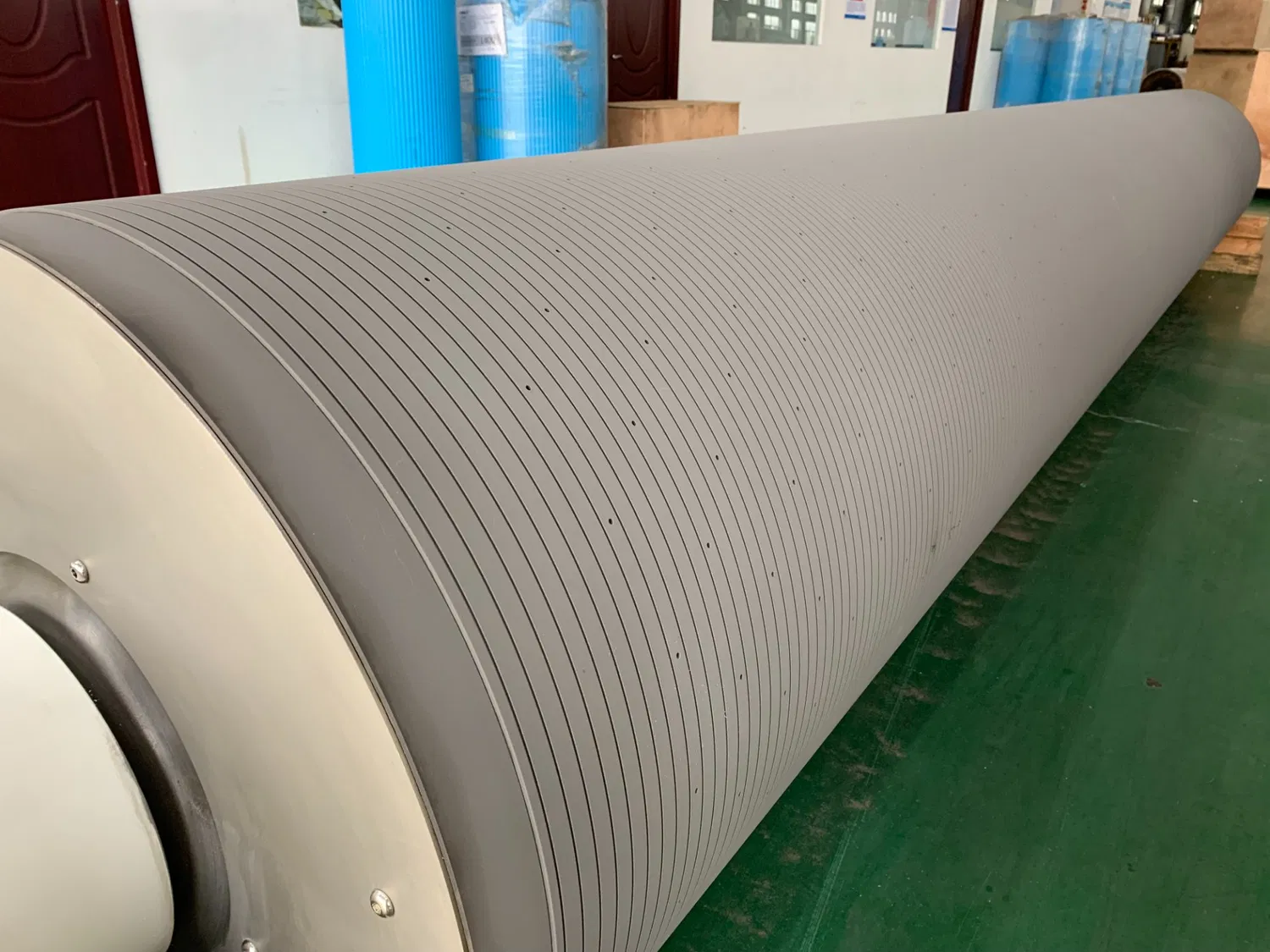

When considering a Bow Curved Roll for Recycled Paper Making Machinery (Spare Part), potential buyers, whether large mills or smaller operations, need to delve into its technical specifications. These rolls are complex assemblies comprising a fixed axle (bowed shaft), a set of freely rotating spools or a continuous sleeve mounted on bearings, and robust sealing systems to protect the internal components from moisture and debris – especially critical in the wet and sometimes contaminated environment of recycled paper lines. Key parameters include the overall length of the roll, the amount and degree of curvature (expressed as deflection or height of the bow), the material composition of the shaft and sleeve, the type of bearings used (often sealed and high-load capacity), and the surface coating of the sleeve. The sleeve surface finish is particularly important; it can be rubber, polyurethane, or even specialized abrasion-resistant coatings designed to withstand the potentially abrasive nature of recycled fibers while providing optimal grip without damaging the delicate web. The curvature is precisely engineered for specific machine widths and paper grades to achieve the desired spreading effect without causing undue stress on the web. Our manufacturing expertise focuses on these details, ensuring each Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) meets stringent performance requirements for durability, balance, and effectiveness in preventing defects like wrinkles and baggy edges.

Core Advantages and Performance Benefits

Investing in a high-quality Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) yields significant operational advantages. The primary benefit is its effectiveness in improving paper quality by eliminating defects caused by improper web handling. By consistently spreading the web, it prevents wrinkles, which are a common issue in paper production, especially with variations in web tension and moisture. This leads to a flatter, more uniform sheet, essential for subsequent processing stages like calendering, coating, or printing. Beyond quality, the bowed roll plays a vital role in enhancing machine efficiency. By stabilizing the web and reducing slack edges, it minimizes the likelihood of web breaks, a major cause of costly downtime. Fewer breaks mean increased uptime, higher throughput, and improved productivity. Furthermore, a well-engineered roll with a precise curvature and smooth-running bearings reduces friction and wear, contributing to lower energy consumption and reduced maintenance needs. The longevity and reliable performance of a quality Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) translate directly into lower operating costs and a higher return on investment over its lifespan. Its contribution to both quality and efficiency makes it a critical component for any mill focused on optimizing its recycled paper production.

Application Across Different Sections of the Paper Machine

The versatility of the Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) is evident in its application across various sections of the paper machine, each location leveraging its web-spreading capabilities for specific purposes. In the press section, bowed rolls can help dewater the sheet evenly and prevent felt wrinkles. In the dryer section, where significant shrinkage occurs, they are essential for managing tension and width, preventing dryer wrinkles, and ensuring the sheet remains flat for slitting and winding. Positioned before the size press or coater, a bowed roll prepares the web for even application of surface treatments. Critically, before the winder, it ensures a tight, evenly wound reel free from wrinkles and telescoping. The specific design, including the amount of curvature and the surface material, is often tailored to the conditions and requirements of its intended location within the machine. For example, rolls in wetter sections require superior sealing and corrosion resistance, while those in dryer or calender sections may need surfaces resistant to heat or pressure. Understanding these specific application needs allows us to recommend or manufacture the optimal Bow Curved Roll for Recycled Paper Making Machinery (Spare Part), ensuring maximum effectiveness and lifespan regardless of where it is installed in your production line.

Precision Manufacturing and Uncompromising Quality Control

As a dedicated manufacturer of critical paper machine components, including the Bow Curved Roll for Recycled Paper Making Machinery (Spare Part), our production process is built on a foundation of precision engineering and rigorous quality control. The unique geometry of a bowed roll demands extremely tight tolerances during manufacturing. We utilize advanced CNC machining for forming the bowed axle to ensure the exact curvature is achieved along its entire length. High-precision grinding and polishing techniques are employed on the sleeve surface to achieve the required finish for optimal web interaction and minimal wear. The assembly process involves careful selection and installation of high-quality, sealed bearings designed to withstand the harsh operating conditions, including high speeds, temperatures, and moisture. A crucial step is dynamic balancing; each roll is meticulously balanced at operating speeds to eliminate vibrations that could negatively impact paper quality or cause premature wear on the roll and surrounding machinery. Our quality control protocols include thorough inspections at every stage, from raw material sourcing to final assembly and testing. Dimensional checks, surface finish measurements, bearing runout tests, and dynamic balancing reports are standard procedures. This unwavering commitment to quality ensures that every Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) leaving our facility delivers reliable, high-performance service in the field, meeting or exceeding industry standards and customer expectations.

Customization Options and Global Supply Reliability

Recognizing that paper machines vary significantly in size, design, and application, we offer extensive customization options for our Bow Curved Roll for Recycled Paper Making Machinery (Spare Part). Whether you need a specific length, a precise amount of bow, a specialized surface material (rubber, polyurethane, chrome, or other coatings) for particular paper grades or process conditions, or a unique mounting arrangement to integrate with your existing machine, our engineering team can work with you to design and manufacture a roll that fits your exact requirements. This flexibility is essential for maximizing the performance gains from replacing or upgrading your bowed rolls. Beyond customization, our capabilities extend to ensuring a reliable and efficient global supply chain. We maintain significant production capacity and manage inventory effectively to facilitate quick lead times for standard and commonly requested custom configurations. Our packaging is designed to protect the rolls during transit, regardless of destination. We have established logistics networks to ship our Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) worldwide, ensuring that mills globally can access high-quality components when they need them, minimizing downtime associated with waiting for parts. Our aim is to be a stable and responsive supplier, providing the components necessary to keep your recycled paper production running smoothly.

Ensuring Durability and Longevity in Demanding Environments

The environment within a paper machine, especially one processing recycled fibers, is inherently challenging. Components are subjected to moisture, heat, pressure, chemical exposure, and physical abrasion. The Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) is specifically designed to withstand these conditions while maintaining its precise geometry and smooth operation over extended periods. The materials selected for the axle and sleeve are chosen for their strength, corrosion resistance, and wear properties. Surface coatings, whether rubber or advanced polymers, are engineered to provide durability against abrasion from the paper web and process chemicals, as well as resistance to aging and cracking. The sealing system protecting the bearings is critical; our seals are robust, multi-barrier designs that effectively prevent water, steam, and contaminants from entering the bearing housing, which is a common cause of premature roll failure. The quality of the bearings themselves also plays a significant role in the roll's lifespan and reliability under load and speed. By focusing on high-quality materials, precision manufacturing, effective sealing, and dynamic balancing, we build Bow Curved Rolls that offer exceptional durability and longevity, minimizing the frequency of replacements and the associated costs and downtime. This focus on reliability is a key reason customers trust us for their critical spare parts.

Flexible Purchase Options and Comprehensive Support

We understand that our customers range from large international paper corporations to smaller independent mills or maintenance workshops. Therefore, we have structured our purchasing process to be flexible and accessible, whether you represent a large business seeking wholesale quantities or an individual buyer needing a single replacement part. We support various order quantities, from single units for targeted replacements or trials to bulk orders for stocking or multiple machine overhauls. Customization is available regardless of order size. For customers needing to verify suitability or performance, sample arrangements can be discussed. We offer diverse payment options to accommodate different business preferences and structures. Beyond the initial purchase, our commitment extends to providing comprehensive after-sales support. Our technical team is available to provide guidance on roll selection, installation best practices, and troubleshooting any operational issues that may arise. We also ensure availability of related spare parts, such as bearing housings or seals, if needed separately. Our goal is not just to supply a component but to be a partner in your production success, offering expertise and support to ensure you get the maximum value and performance from your Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) throughout its operational life. Your successful and efficient production is our priority.

Choosing the Right Partner for Your Bow Curved Roll Needs

Selecting the appropriate Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) and a reliable supplier is a decision that impacts your production efficiency, paper quality, and maintenance costs. With the unique challenges of recycled paper production, the precision, durability, and consistent performance of every component are vital. By partnering with a manufacturer that possesses deep technical expertise, utilizes advanced manufacturing processes, adheres to stringent quality control standards, and offers flexible customization and global supply capabilities, you ensure access to high-quality components designed to meet the specific demands of your machinery and process. Our commitment to excellence in the design, manufacturing, and supply of the Bow Curved Roll for Recycled Paper Making Machinery (Spare Part) makes us a trusted source for mills worldwide. We understand the pressures of maintaining high output while managing costs and quality, and we engineer our products to contribute positively to these goals. Choosing our bowed rolls means investing in reliable performance, reduced downtime, improved paper quality, and long-term operational efficiency for your recycled paper production line. Let our expertise become an asset to your operation, helping you achieve optimal results.

For more detailed information, please visit our official website: Bow Curved Roll for Recycled Paper Making Machinery