In the demanding world of tissue and toilet paper production, every component of the manufacturing line plays a critical role in ensuring efficiency, quality, and consistency. A seemingly simple part, often overlooked by those outside the industry, is the imitation stone roll. This specialized roller is far more than just a cylinder; it is a precision-engineered spare part vital to the final texture, appearance, and even the winding quality of the finished toilet paper product. Its unique surface characteristics are designed to impart a specific pattern or finish onto the paper web during the converting process, contributing significantly to the perceived quality and feel of the product that consumers ultimately use. The reliable performance of this roller is paramount. A worn, damaged, or incorrectly specified imitation stone roll can lead to a cascade of issues, from inconsistent paper finish and reduced production speed to excessive waste and increased downtime. Understanding the critical function and required precision of this component is the first step in appreciating the value of a high-quality imitation stone roll for toilet paper production machines, and why sourcing from a reputable manufacturer and supplier is non-negotiable for producers aiming for optimal results and operational longevity.

The primary function of the imitation stone roll within a toilet paper production line is to provide the necessary grip and texture for the paper web during the crucial winding or embossing stages. Unlike smooth rollers, its surface is carefully crafted to mimic the texture of stone, allowing it to effectively hold and guide the delicate paper without tearing, while simultaneously imparting a specific pattern or helping to consolidate plies. This intricate balance of grip and gentle handling is essential for producing rolls that are tightly wound, consistently textured, and free from defects. The specific pattern or finish of the roll’s surface can vary depending on the desired final product characteristics, ranging from subtle textures that enhance softness to more pronounced patterns for specific branding or structural purposes. As a spare part, the imitation stone roll is subject to constant friction and pressure, enduring significant wear and tear over time. Its durability and the integrity of its surface are therefore critical factors influencing its lifespan and the sustained quality of the toilet paper produced. When seeking a replacement, identifying a roller that meets stringent technical specifications and boasts superior material quality is vital to maintain production efficiency and avoid premature failure, ensuring the toilet paper impression roller replacement is a value-adding investment rather than a temporary fix that compromises quality.

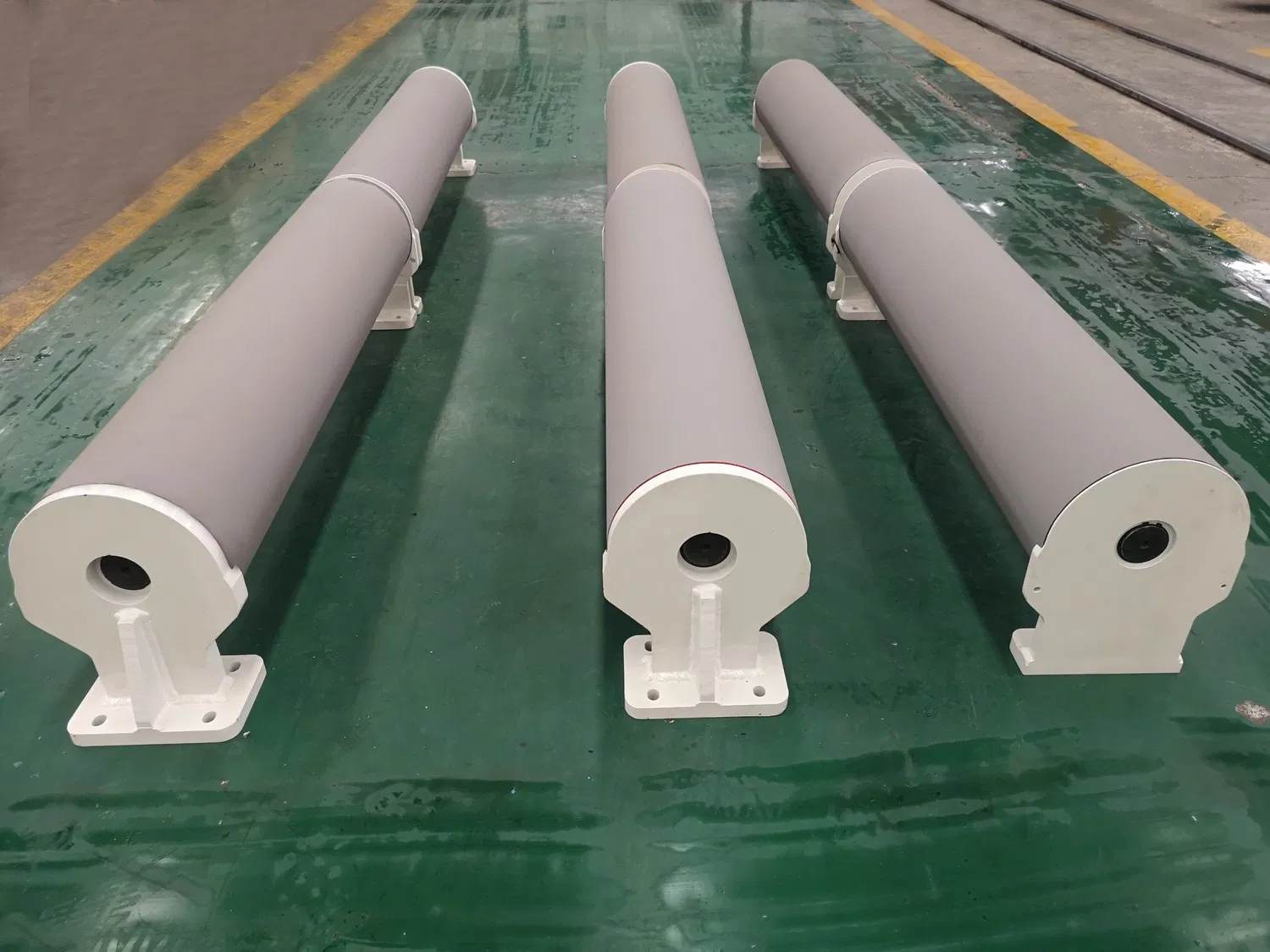

Precision Engineering: The Core of the Imitation Stone Roll TP-SR100

Our flagship product, the Imitation Stone Roll TP-SR100, stands as a testament to precision engineering in the field of tissue converting machinery spare parts. This roll is meticulously manufactured to deliver exceptional performance and longevity in demanding production environments. Key features include a robust core material selected for its strength and dimensional stability, often high-grade steel or cast iron, providing a solid foundation. The critical working surface is where the Imitation Stone Roll TP-SR100 truly distinguishes itself. It undergoes a specialized surface treatment process, typically involving thermal spray coating or electrochemical deposition, to create a durable and consistent imitation stone texture. This coating is not merely aesthetic; it is engineered for optimal hardness, wear resistance, and a precise co-efficient of friction that ensures reliable paper handling. Technical specifications for the TP-SR100 typically include precise dimensions (diameter, length, shaft configurations) tailored to fit a wide range of existing toilet paper production machines, strict tolerances for runout and concentricity to prevent vibration and ensure uniform pressure, and specific surface roughness parameters to achieve the desired paper finish. The design and manufacturing process prioritize these technical parameters to guarantee that the Imitation Stone Roll TP-SR100 integrates seamlessly into your existing line and performs flawlessly from day one, contributing directly to consistent product quality and line efficiency.

Beyond the fundamental structure and surface, the Imitation Stone Roll TP-SR100 incorporates several design advantages that contribute to its superior performance and durability. For example, advanced coating technologies are employed to enhance abrasion resistance, significantly extending the operational life of the roller compared to conventional methods. This specialized coating also offers improved resistance to chemical interactions with any additives or moisture present in the paper web or processing environment, preventing degradation over time. Furthermore, the roller's internal structure and mounting points are engineered for high rigidity, minimizing deflection under operational loads and maintaining consistent nip pressure across the entire width of the paper web. This uniform pressure is vital for achieving a consistent finish and ensuring tight, evenly wound rolls. The TP-SR100 is designed with ease of installation and maintenance in mind, featuring standard interfaces and robust construction that simplifies integration into existing machinery and reduces the complexity of routine checks. These combined features – the selection of premium materials, precision surface engineering, robust structural design, and consideration for practical application – give the Imitation Stone Roll TP-SR100 a distinct competitive edge, offering unparalleled reliability and performance for toilet paper producers globally who require a high-quality spare part they can trust.

Manufacturing Excellence and Rigorous Quality Control

Producing high-quality Imitation Stone Rolls requires more than just good design; it demands manufacturing excellence underpinned by state-of-the-art facilities and rigorous quality control processes. Our manufacturing operations are equipped with advanced CNC machining centers capable of achieving the tight dimensional tolerances and precision finishes required for critical spare parts like the Imitation Stone Roll for Toilet Paper Production Machines. We utilize specialized surface treatment equipment, including thermal spray booths and sophisticated coating application systems, ensuring the imitation stone texture is applied uniformly and with the correct properties across the entire roller surface. The process is carefully controlled, monitoring parameters such as temperature, pressure, and application speed to achieve the desired hardness, texture depth, and bond strength of the coating. This level of control is crucial for ensuring the roller's surface performs consistently throughout its lifespan and provides the optimal grip and finish for the paper web. Our facilities are designed for efficiency and scale, allowing us to meet substantial production demands while maintaining stringent quality standards, positioning us as a reliable tissue paper machine ceramic coated roll supplier for large-scale operations.

Quality control is not an afterthought but an integral part of our manufacturing philosophy, embedded at every stage of the production process for the Imitation Stone Roll TP-SR100. Raw materials are subjected to incoming inspections to verify their composition and properties meet our specifications. Throughout machining and surface treatment, in-process checks are conducted to monitor dimensions, tolerances, and coating characteristics. This includes using precision measuring instruments such as micrometers, calipers, profilometers (to measure surface roughness and texture depth), and coordinate measuring machines (CMMs) to verify geometric accuracy. The final inspection is comprehensive, involving a detailed visual examination, dimensional checks, surface property analysis, and functional testing where applicable. Every Imitation Stone Roll TP-SR100 must pass these rigorous checks before it is cleared for shipment, ensuring that each unit leaving our facility meets the high standards our customers expect for such a critical spare part. Our commitment to quality is reflected in our adherence to international quality management standards, providing customers with the assurance that they are receiving a product manufactured to the highest levels of precision and reliability.

Addressing Production Challenges with Durable TP-SR100 Rolls

Toilet paper production lines face several inherent challenges, particularly concerning the lifespan and performance of critical moving parts like the impression roll. Wear and tear on a standard roller can lead to inconsistent paper texture, reduced grip resulting in poor winding, and ultimately, increased downtime for replacements. The Imitation Stone Roll TP-SR100 is specifically engineered to address these problems head-on. Its advanced, wear-resistant coating significantly prolongs the operational life of the roller, drastically reducing the frequency of replacements. This translates directly into less downtime for roller changes, leading to increased overall equipment effectiveness (OEE) and higher production output. The consistent and precise surface texture ensures uniform pressure application across the paper web, resulting in a beautifully consistent paper finish and tightly wound, perfectly formed rolls every time. Poor winding and roll formation are common issues that can lead to waste and customer complaints, but the reliable grip provided by the TP-SR100 surface eliminates these problems. By investing in a durable impression roller for toilet paper winding like the TP-SR100, manufacturers can significantly improve product quality, reduce operational costs associated with frequent spare part changes, and boost the overall efficiency and profitability of their production lines, solving common issues related to unreliable rollers.

The applications of the Imitation Stone Roll TP-SR100 extend across various stages and configurations of toilet paper production and converting lines. It is commonly used in embossing units, where its surface texture helps to create intricate patterns on the paper, and in winding stations, where it provides the necessary friction and support for forming the final paper rolls. Whether your line employs through-air drying (TAD) technology or conventional processes, the TP-SR100 is designed to integrate seamlessly and perform optimally. Its robust construction makes it suitable for high-speed production environments where rollers are subjected to significant mechanical stress. The ability to maintain its surface properties under continuous operation is crucial for lines running around the clock. Furthermore, the precise manufacturing allows for tailored dimensions and interfaces, making it compatible with machinery from a wide range of manufacturers, ensuring that toilet paper producers can easily source a reliable replacement regardless of their specific equipment setup. This adaptability makes the TP-SR100 an ideal spare part solution for enhancing performance and reliability in virtually any modern toilet paper production facility, ensuring smooth operations from the paper mill down to the converting line.

Flexible Supply Solutions for Businesses and Individuals

Understanding the diverse needs of our customers, we offer flexible supply solutions for the Imitation Stone Roll for Toilet Paper Production Machines, catering to both large-scale business operations and individual workshops or smaller production units. We recognize that a major manufacturing plant may require multiple rollers for continuous operation and strategic stocking, while a smaller business might only need a single replacement part. Our order processing system is designed to accommodate various order quantities, from single units for urgent replacements to bulk orders for inventory management. This flexibility ensures that businesses of all sizes have access to the high-quality Imitation Stone Roll TP-SR100 they need, precisely when they need it, without unnecessary restrictions or minimum order quantities that hinder accessibility. Our supply chain is structured to handle both large shipments destined for international ports and smaller, individualized deliveries, ensuring that every customer receives the same level of professional service and attention, making us a dependable partner whether you're a global corporation or a specialized converter.

Customization is another key aspect of our service offering, particularly for the Imitation Stone Roll TP-SR100. While we offer standard configurations, we understand that production machines can have unique specifications based on their age, manufacturer, or modifications. We provide tailored solutions, working closely with customers to produce rollers with specific dimensions, shaft configurations, surface textures, or material requirements. Our engineering team can assist in analyzing your existing setup and recommending or designing a roller that perfectly fits your machinery and production needs. This includes matching critical parameters such as outside diameter, face length, journal dimensions, keyway requirements, and even specific surface roughness profiles if needed. For customers evaluating our product or requiring confirmation of compatibility, we can discuss sample availability and technical consultations. This commitment to flexibility and customization ensures that when you choose our Imitation Stone Roll for Toilet Paper Production Machines, you receive not just a standard part, but a solution optimized for your specific operational demands, simplifying the process of finding the correct converting line stone finish roller for your equipment.

Global Reach and Dependable Logistics

Our manufacturing capacity and established logistics network enable us to offer global supply capabilities for the Imitation Stone Roll TP-SR100. We serve customers across continents, ensuring that toilet paper producers around the world have access to our high-quality spare parts. Our production planning accounts for international demand, maintaining inventory levels that support quick lead times for standard products. For customized orders, our efficient manufacturing process allows us to minimize turnaround time from design confirmation to shipment. We understand that timely delivery is crucial for minimizing downtime in a production environment, and our logistics team works diligently to ensure prompt and reliable shipping via various transportation modes – air, sea, or land – depending on urgency and location. We partner with reputable shipping providers to ensure secure and efficient delivery to your facility, managing the complexities of international logistics, including customs procedures and documentation. This global reach and focus on efficient supply chain management position us as a reliable and accessible supplier for the Imitation Stone Roll for Toilet Paper Production Machines, wherever your operations are located.

Furthermore, our commitment extends beyond just providing the spare part; we offer comprehensive after-sales support to ensure our customers maximize the value of their Imitation Stone Roll TP-SR100 investment. This includes technical assistance for installation, guidance on optimal operational parameters, and advice on maintenance procedures to prolong the roller's lifespan. Should any issues arise, our support team is readily available to provide expert troubleshooting and solutions. We stand behind the quality of our products, and our after-sales service is a reflection of that commitment. We also offer diverse payment options to facilitate smooth transactions for our global clientele, accommodating various business practices and currencies where possible. Our aim is to build long-term partnerships with our customers, providing not just a product, but a complete solution that includes expert support and reliable service, making the process of sourcing critical toilet paper machine spare parts as seamless and efficient as possible for both B2B buyers and individual workshops.

Investing in Quality for Sustainable Production

Choosing the right spare parts for your toilet paper production machines is an investment in the sustainability and profitability of your operation. A high-quality Imitation Stone Roll, such as our Model TP-SR100, contributes significantly to this by reducing downtime, minimizing waste due to inconsistent product quality, and extending the lifespan of associated machinery components by providing smooth, controlled contact. The superior durability means fewer replacements are needed over time, reducing both direct costs and the environmental impact associated with manufacturing and shipping new parts. By ensuring consistent product quality, manufacturers can maintain customer satisfaction and avoid costly rejects or returns. The reliability of the TP-SR100 allows production managers to plan with greater certainty, optimizing schedules and resource allocation. In essence, investing in a premium Imitation Stone Roll for Toilet Paper Production Machines is a strategic decision that pays dividends in operational efficiency, product quality, and long-term cost savings, reinforcing the importance of quality components in achieving sustainable, high-performance manufacturing.

Our expertise in manufacturing precision industrial rollers, combined with our specific focus on the needs of the tissue and paper converting industry, allows us to deliver spare parts like the Imitation Stone Roll TP-SR100 that truly meet the challenges of modern production. We continuously research and develop our surface treatment technologies and material science to ensure our rollers remain at the forefront of performance and durability. Our understanding of the intricate dynamics of paper handling and winding informs every aspect of our design and manufacturing process. We don't just produce rollers; we engineer solutions that enhance the performance of your toilet paper production machines. Whether you are looking to replace a worn-out roll, upgrade your existing machinery for better performance, or stock critical spares, our Imitation Stone Roll TP-SR100 offers a reliable and high-performance solution. We invite you to learn more about how our precision-engineered rollers can benefit your operation and contribute to consistent, high-quality toilet paper production.

For more detailed information, please visit our official website: Imitation Stone Roll TP-SR100