In the world of paper manufacturing, printing, and converting, maintaining the integrity of paper rolls is paramount. These massive cylinders of paper represent significant investment, and any damage – whether from transit, storage, or handling – can render them unusable in their original form. The immediate reaction might be to write off the damaged portion, or even the entire roll, as waste. However, this is where the critical process of paper roll recovering comes into play. It's not just about repairing; it's about reclaiming valuable material that would otherwise end up being repulped at a loss or worse, sent to landfill. The financial implications of damaged rolls can be substantial, impacting production schedules, material costs, and overall profitability. Recognising the potential to salvage this material is the first step towards a more efficient and sustainable operation. Have you ever truly calculated the cost of discarded damaged paper rolls over a year? It can be an eye-opening figure, highlighting the immense value locked within what might seem like waste.

Common Types of Paper Roll Damage Affecting Recovery

Understanding the nature of the damage is fundamental to successful paper roll recovering. Not all damage is created equal, and the type dictates the feasibility and method of recovery. One of the most common culprits is moisture damage, which can cause swelling, distortion, and loss of paper strength, often leading to rippling or "wavy" edges. Telescoping, where the layers of the roll shift horizontally, is another frequent issue, usually caused by sudden stops or improper handling during transport. Crushing damage, often occurring at the core or edges, compromises the roll's structure and can make it difficult to unwind smoothly. Edge damage, splits, or dents can happen from drops or impacts. Internal damage, which isn't immediately visible from the outside, can be particularly insidious, sometimes only revealed when the roll is put into production, causing breaks and downtime. Identifying these specific types of damage is crucial for the initial assessment process, as some forms of damage are more amenable to recovery than others. A severely crushed core, for instance, presents a different challenge than simple edge damage or external moisture exposure.

Each type of damage requires a specific approach during the paper roll recovering process. Moisture damage might necessitate cutting away the affected outer layers, while telescoping often requires controlled unwinding and rewinding under tension. Crushed cores might need specialised core repair or replacement techniques if the inner layers are still salvageable. Splits and edge damage typically involve slitting the roll to remove the damaged section entirely, creating narrower, but still usable, rolls. The severity and depth of the damage are also key factors. Shallow damage on the outer wraps is relatively easy to address, but damage that extends deep into the core or affects a large percentage of the roll diameter poses a greater challenge and may require more complex or time-consuming recovery methods. Proper assessment using tools like moisture meters, core indicators, and visual inspection is therefore a non-negotiable step before attempting any recovery work, ensuring that the chosen method is appropriate and cost-effective for the specific damage encountered.

Assessing the Potential for Paper Roll Recovering

Before embarking on any recovery effort, a thorough assessment of the damaged roll is essential to determine if paper roll recovering is viable and economically sensible. This isn't just a quick look; it's a systematic evaluation. Key factors to consider include the type and extent of the damage, the grade and value of the paper, the current market demand for that specific paper, and the cost associated with the recovery process itself. Is the paper a high-value specialty grade or a standard packaging board? The potential return on investment for recovery varies significantly. Internal damage assessment, often requiring specialized equipment or the expertise of a seasoned professional, is particularly important as surface appearances can be deceptive. Sometimes, what looks like minor external damage hides catastrophic internal issues, while in other cases, severe-looking external damage might only affect the outer wraps. Franky speaking, making an incorrect assessment can lead to wasted time and resources on a roll that cannot be effectively salvaged, or conversely, discarding a roll that could have been profitably recovered.

The assessment process should also consider the logistical aspects. How easy is it to move the damaged roll? What are the safety implications of handling it? Is there sufficient space and appropriate equipment available for the recovery process? For larger operations or more complex damage, partnering with a professional service specializing in **salvaging damaged paper rolls** can be significantly more efficient than attempting recovery in-house with limited resources or expertise. They have the diagnostic tools and experience to quickly and accurately assess the recovery potential. The goal of the assessment is to make an informed decision: Is the cost of recovering the usable paper less than the value of that recovered paper? Does recovering the paper offer a better return than simply selling the damaged material as salvage or waste? A clear understanding of these factors is paramount to successful **paper roll recovering** and maximising the return on damaged stock.

Core Mechanical Approaches to Paper Roll Recovering

Once the decision to proceed with **paper roll recovering** is made, mechanical methods are often the primary tools employed. The simplest technique, particularly for edge damage or limited moisture ingress on the outer layers, is controlled slitting. This involves unwinding the damaged roll and using precision knives to cut away the damaged section along the length of the web, effectively creating one or more narrower, but undamaged, rolls from the original width. This requires careful alignment and tension control to ensure clean cuts and uniform rolls. Another common method is external rewinding. If the damage is concentrated on the outer wraps, the roll can be rewound onto a new core, allowing the damaged layers to be removed and discarded. This is effective for telescoping or surface impacts. The success of these basic mechanical approaches relies heavily on the skill of the operator and the quality of the rewinding or slitting machinery used. Poorly executed cuts or uneven tension during rewinding can introduce new problems, potentially ruining otherwise salvageable material.

Interestingly enough, even seemingly simple methods like cutting away damage require a nuanced understanding of paper properties. The type of paper, its caliper, and its strength characteristics all influence how it responds to slitting and rewinding tension. Applying too much tension can stretch or damage the paper, while too little can result in loose, unstable rolls. For damage that affects the core area or causes significant distortion, these basic methods may not be sufficient. The key takeaway here is that while the concepts are straightforward, the execution demands precision and experience. Investing in operator training and ensuring equipment is properly maintained and calibrated is crucial for optimising the outcome of these mechanical **paper roll recovering** processes. The goal is always to recover the maximum amount of high-quality paper, minimising waste from the recovery process itself.

Advanced Techniques in Paper Roll Recovering Operations

Beyond basic cutting and rewinding, professional **paper roll recovering** operations employ more advanced techniques to tackle complex damage scenarios. For rolls with distorted cores, special equipment might be used to gently reshape or replace the core while preserving the surrounding paper. This is a delicate process, as excessive force can damage the inner wraps. Rolls that have experienced significant telescoping or crushing can sometimes be corrected using sophisticated rewinding machines with variable tension control and alignment mechanisms that slowly pull the layers back into place or compensate for the distortion as the paper is rewound. For severe internal damage or multiple damaged sections, a full rewinding process might be necessary where the entire roll is unwound, inspected, and the damaged portions are carefully removed or spliced out before rewinding onto a new core. This allows for internal assessment and selective removal of compromised material.

Some types of damage, particularly related to shape distortion like 'egg-shaped' rolls caused by external pressure, might require specialized heating or conditioning processes combined with controlled rewinding to restore roundness. These advanced **methods for salvaging paper rolls** are often proprietary to professional recovery services and require significant investment in technology and operator expertise. They push the boundaries of what's possible, allowing for the recovery of rolls that would have been considered unsalvageable just a few years ago. Frankly speaking, attempting these advanced techniques without the right equipment or experience can lead to further damage and a complete loss of the roll. This is where the value of partnering with an expert service becomes most apparent, leveraging their specialised capabilities for complex recovery challenges.

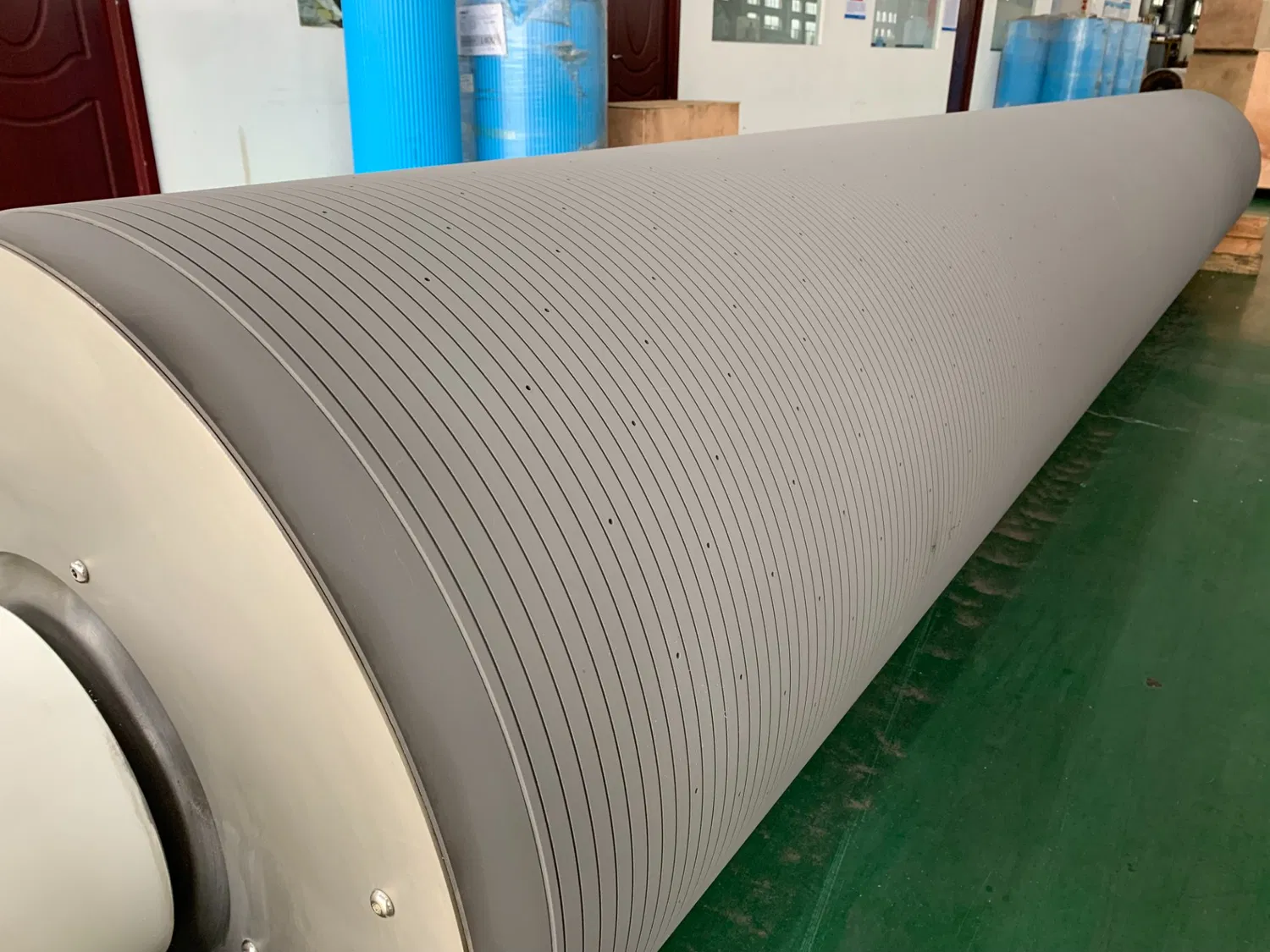

The Equipment Powering Professional Paper Roll Recovering

Effective **paper roll recovering** relies heavily on having the right tools for the job. At the heart of most recovery operations are specialized rewinding machines. These aren't just standard production winders; they are often designed with features specifically for handling damaged or distorted rolls. This includes robust unwind stands capable of supporting heavy, potentially unbalanced rolls, precision tension control systems that can adapt to varying paper conditions, and highly accurate slitting mechanisms for removing damaged edges or creating narrower rolls. Some advanced machines incorporate features like automatic edge guiding to ensure straight rewinding, or core chucks designed to handle damaged cores. Roll handling equipment is also crucial, given the weight and size of paper rolls. Specialized clamps, roll turnovers, and transport systems ensure rolls can be safely and efficiently moved through the recovery process.

For assessing internal damage or moisture levels, tools like core viewers and moisture meters are essential. Core viewers, essentially industrial endoscopes, allow operators to inspect the inside of the roll core for crushing, splits, or moisture damage without having to unwind the entire roll. Moisture meters help quantify the extent of water damage. Safety equipment is paramount; handling heavy, potentially unstable rolls requires robust safety protocols and equipment like protective barriers, emergency stops on machinery, and proper lifting gear. In my experience, the quality and sophistication of the equipment directly correlate with the range and complexity of damages that can be effectively addressed. A well-equipped facility can handle everything from simple edge trims to complex core repairs and distortion correction, significantly increasing the percentage of damaged stock that can be successfully recovered.

The Economic and Environmental Imperative for Paper Roll Recovering

The **benefits of paper roll reclamation** extend far beyond simply dealing with damaged goods; they offer compelling economic and environmental advantages. Economically, recovering damaged rolls saves the cost of repurchasing new paper. While there's a cost associated with the recovery process, it is invariably a fraction of the original material cost. This directly impacts the bottom line, turning potential losses into usable inventory. Furthermore, reducing the volume of damaged rolls sent for repulping at a lower value, or worse, disposal, avoids associated costs like transport and tipping fees. For printers and converters, having a reliable process for **salvaging damaged paper rolls** ensures a more consistent material supply, reducing disruptions to production schedules caused by unexpected shortages from damaged stock. It's a proactive approach to inventory management and cost control that many leading companies are now embracing.

From an environmental perspective, the advantages are equally significant. Every ton of paper recovered means less virgin fiber or recycled pulp needs to be processed, saving energy, water, and reducing greenhouse gas emissions associated with paper production. It also reduces the burden on landfills. Implementing a robust **paper roll recovering** program is a tangible step towards sustainability goals and demonstrates a commitment to reducing waste within the supply chain. Many companies are under increasing pressure from customers and regulatory bodies to improve their environmental footprint. Optimising resource utilisation through paper roll recovery is a clear way to meet these expectations. To be honest, it's a win-win scenario: saving money while simultaneously reducing environmental impact. This dual benefit makes a strong case for integrating professional recovery services into standard operational procedures.

Navigating the Process of Paper Roll Recovering with a Partner

While some large facilities may invest in their own recovery equipment and expertise, many companies find it more efficient and cost-effective to partner with a specialized service for their **paper roll recovering** needs. Choosing the right partner is crucial. Look for a company with extensive experience in handling various paper grades and types of damage. They should have state-of-the-art equipment capable of performing a range of recovery techniques, from simple slitting to complex core repair. Transparency in their assessment process and pricing is also important. A good partner will provide a clear report on the condition of each damaged roll and a detailed quote for the proposed recovery work, explaining why certain rolls are recoverable and others are not. They should also demonstrate a strong commitment to safety and environmental responsibility.

The process with a partner typically begins with transportation of the damaged rolls to their facility. Upon arrival, their experts perform the detailed assessment discussed earlier. Based on this, they determine the most appropriate recovery method for each roll. The recovery work is then performed using their specialized equipment and skilled operators. Recovered rolls are typically rewound onto new cores, often wrapped and labeled according to the customer's specifications, ready to be integrated back into their usable inventory. Unrecoverable material is handled responsibly, usually sent for high-grade repulping. Working with a professional service simplifies the process for the paper owner, eliminating the need for in-house equipment investment, maintenance, and specialized training. It provides a reliable, expert solution for managing damaged stock and maximizing the return on their material investment. It's worth noting that a strong partnership built on trust and communication is key to a successful ongoing recovery program.

So, what should your next steps be if you're frequently dealing with damaged paper rolls? First, conduct an internal audit to understand the volume and types of damage you encounter. Quantify the potential cost savings by estimating the value of the paper currently being discarded or sold at a loss. Then, research potential partners who specialize in **how to recover damaged paper rolls**. Contact a few prospective services, discuss your specific needs, and inquire about their assessment process, capabilities, and pricing structure. Ask for references or case studies demonstrating their success in recovering similar paper grades or damage types. Implementing a professional **paper roll recovering** strategy is not just about fixing damaged goods; it's a strategic business decision that enhances profitability, improves operational efficiency, and supports corporate sustainability goals. Don't let damaged stock become a perpetual drain on your resources; explore the possibilities of expert recovery today.

For more detailed information, please visit our official website: paper roll recovering