In the demanding world of paper manufacturing, printing, packaging, and converting, machinery operates at incredible speeds and under immense pressure. The heart of many of these operations lies in the rolls – guide rolls, press rolls, calendar rolls, winding and unwinding rolls, and many more. These components are critical to process stability and product quality. However, even the slightest imbalance in a paper roll can have cascading negative effects, leading to vibration, wear, damage, and ultimately, costly downtime and reduced product quality. This is precisely why a professional paper roll balancing service isn't just beneficial; it's often essential for maintaining efficiency, longevity, and profitability in these industries. Understanding the subtle yet significant impact of roll imbalance is the first step towards appreciating the value that expert balancing brings to the table.

The Silent Threat: Understanding Roll Imbalance and Its Costs

Roll imbalance might seem like a minor issue on the surface, but its effects are far-reaching and insidious. Imagine a perfectly cylindrical roll with its mass distributed evenly around its rotational axis. When this distribution is uneven, even slightly, it creates a centrifugal force during rotation that doesn't cancel out. This results in a net force acting outwards, changing direction with every turn – what we perceive as vibration. Imbalance can be static, meaning the heavy spot is concentrated at one axial location, or dynamic, where the imbalance varies along the roll's length, requiring measurement and correction in at least two planes. Common causes include manufacturing tolerances, material inconsistencies, wear and tear, accumulation of process materials (like paper dust, ink, or adhesive), or even slight bending or distortion over time. Frankly speaking, any deviation from a perfectly uniform mass distribution will lead to imbalance, and the higher the speed of rotation, the more pronounced and damaging the resulting forces become. The costs associated with this silent threat manifest in numerous ways, impacting both the machinery and the end product.

Digging deeper into the consequences, the primary victim of roll imbalance is the machine itself. Excessive vibration puts tremendous stress on bearings, seals, and structural components. Bearings, designed for smooth rotation, are subjected to oscillating radial loads that accelerate fatigue and drastically reduce their lifespan. This often leads to premature failure, unplanned maintenance interventions, and expensive replacement parts. Seals can wear out faster, causing leaks or allowing contaminants in. Machine frames can develop cracks over time due to the constant pounding of vibration. Think about a high-speed printing press or a paper machine running large, heavy rolls; the forces generated by even a small imbalance at thousands of revolutions per minute are substantial. In my experience, many unexpected machine failures or chronic maintenance issues can be traced back to overlooked or improperly balanced rolls. Ignoring this can turn minor vibrations into major repair bills and significantly shorten the operational life of valuable equipment.

Beyond mechanical damage, roll imbalance severely compromises production quality, particularly in processes involving continuous webs like paper, film, or foil. Vibration transmits through the web, causing tension fluctuations, tracking issues, and web breaks – frustratingly common occurrences that halt production. In printing, imbalance leads to inconsistent impression pressure, ghosting, or poor registration, resulting in mountains of scrap. In winding or unwinding, it can cause telescoping rolls or uneven edge profiles. For manufacturers aiming for tight tolerances and high cosmetic quality, imbalanced rolls are simply unacceptable. It's worth noting that achieving optimal product quality requires every component in the process chain to function flawlessly, and balanced rolls are fundamental to achieving stability and precision at speed. Have you ever wondered why seemingly identical machines produce different quality outputs? Roll balance is often a critical, hidden factor differentiating top performers from those plagued by issues.

Executing Precision: The Steps in Professional Paper Roll Balancing Service

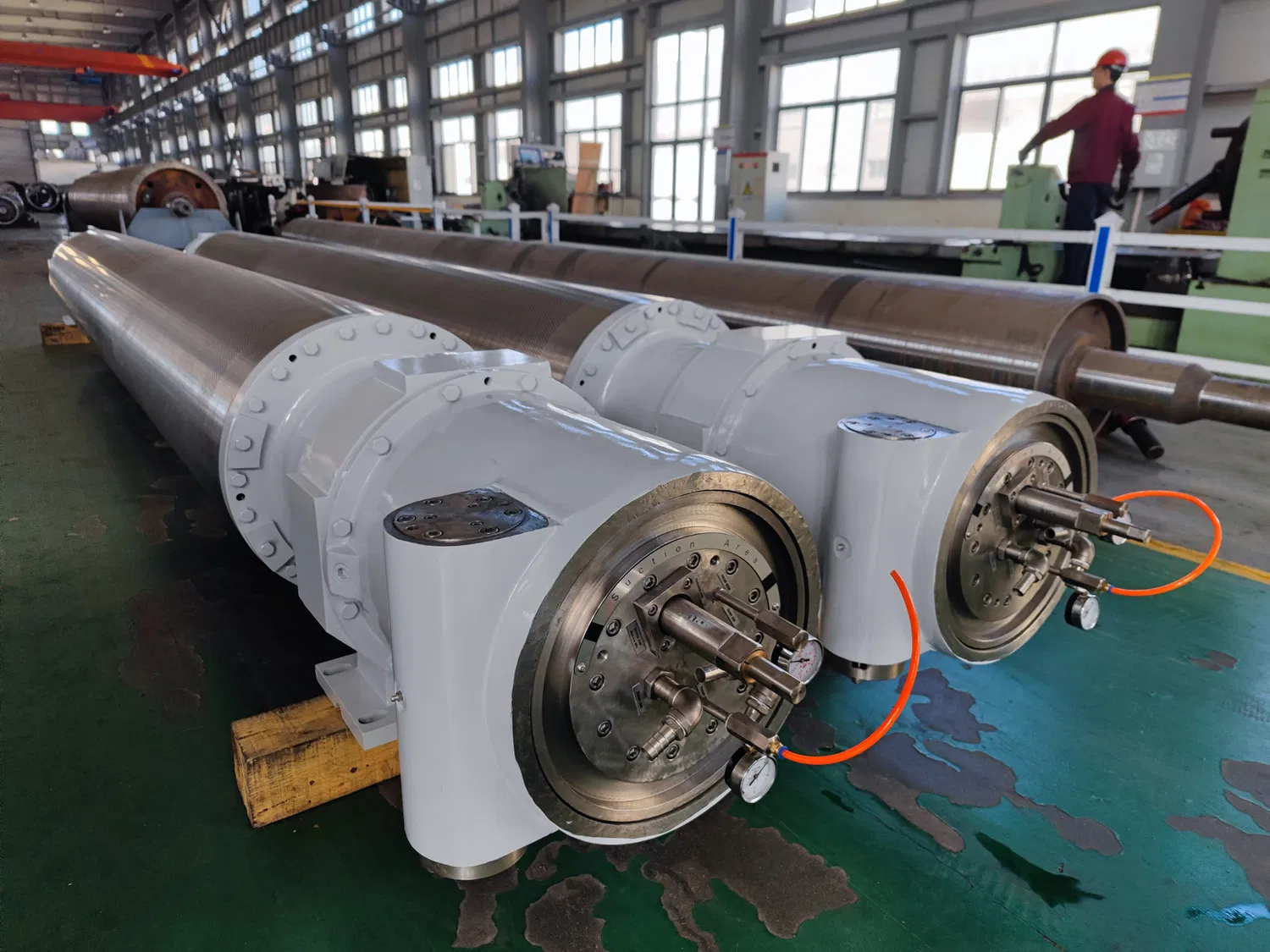

Addressing roll imbalance effectively requires specialized knowledge, equipment, and a precise methodology – characteristics hallmarks of a professional paper roll balancing service. The core principle involves detecting the location and magnitude of imbalance and then adding or removing weight to counteract it, ensuring the mass is evenly distributed relative to the rotational axis. While the concept is simple, executing it, especially for large, heavy industrial rolls, demands significant expertise. The process typically begins with mounting the roll on a specialized balancing machine. These machines feature sensitive sensors that measure the vibration induced by the spinning roll. The data collected allows technicians to determine exactly where the heavy spots are located (both angularly and axially) and by how much weight the roll is out of balance. This diagnostic phase is critical for planning the correction.

Once the imbalance data is captured, the next step is correction. There are several methods for achieving balance, depending on the roll's construction and the nature of the imbalance. Weight can be added by welding balance weights, bolting weights, or sometimes by applying dense materials like epoxy. Alternatively, weight can be removed by grinding material away from specific points on the roll surface or ends, or by drilling holes to reduce mass. The choice of method depends on factors like the required balance tolerance, the roll material, its design, and the operating environment. For instance, a roll operating in a humid environment might require welded weights rather than bolted ones to prevent corrosion issues. Precision is paramount; calculated weights must be added or removed in exactly the right locations and amounts to achieve the desired balance grade. Modern balancing machines guide technicians through this process, ensuring accuracy. After correction, the roll is re-spun on the machine to verify that the vibration has been reduced to within the specified tolerance, confirming the success of the balancing operation.

Achieving Optimal Performance: Why Dynamic Balancing is Crucial for High-Speed Rolls

While static balancing can correct single-plane imbalance and is sufficient for some low-speed applications, it is utterly inadequate for the rolls found in most modern paper and converting machinery. These rolls are often long, operate at high peripheral speeds, and require precision alignment and running characteristics. Dynamic balancing measures and corrects imbalance in at least two planes simultaneously, addressing both static and couple imbalance. Couple imbalance occurs when there are equal heavy spots 180 degrees apart but in different planes along the roll length, creating a twisting moment that static balancing cannot detect or correct. At high speeds, this couple imbalance generates significant forces that can cause severe vibration and instability. Frankly speaking, attempting to run a dynamically imbalanced roll at high speed is inviting trouble. Professional dynamic balancing service uses sophisticated equipment that can detect and correct these complex imbalance issues, ensuring smooth, stable operation even at peak production speeds. This is non-negotiable for critical rolls like press rolls, calendar rolls, and high-speed web handling rolls where stability directly impacts product quality and machine longevity.

Selecting Expertise: What to Look for in a Paper Roll Balancing Service Provider

Given the critical nature of this service, choosing the right provider for your paper roll balancing needs is a decision that shouldn't be taken lightly. DIY attempts, while seemingly cost-saving upfront, often lack the necessary precision, equipment, and expertise, potentially exacerbating existing issues or failing to fully resolve them. A professional paper roll balancing service brings specialized knowledge about different roll types, materials, and operating conditions specific to the paper and converting industries. They possess calibrated, high-precision balancing machines capable of handling rolls of various sizes and weights, and critically, achieving tight balance tolerances (often specified using ISO balance grades like G2.5 or G6.3, which denote the acceptable level of residual imbalance). Beyond the equipment, the technicians' experience is vital. They should be adept at diagnosing complex imbalance issues, selecting appropriate correction methods, and understanding the nuances of balancing different roll constructions, such as those with internal cooling passages, rubber coatings, or complex journal designs. Partnering with experts ensures the job is done right the first time, delivering lasting improvements in machine performance and reliability.

When considering a professional paper roll balancing service, it's helpful to understand the types of services offered and determine which best suits your operational needs. Many providers offer in-house balancing, where you ship your rolls to their facility. This is often suitable for rolls undergoing refurbishment or planned maintenance downtime. However, shipping large, heavy rolls can be expensive and time-consuming. For critical rolls, especially those that are difficult or time-consuming to remove from the machine, or when downtime is extremely costly, on-site balancing becomes an invaluable option. Some providers offer portable balancing equipment and skilled technicians who can perform balancing directly on your machine, or at least within your facility. This dramatically reduces logistics and minimizes downtime, allowing you to address vibration issues quickly and efficiently. Assessing your specific situation – roll size, weight, criticality, machine downtime costs, and logistics – will help determine whether in-house or on-site service is the more practical and economical choice. Interestingly enough, some providers excel in one area, while others offer robust capabilities in both, providing flexibility for their clients.

A key differentiator among providers of paper roll balancing service lies in their process and commitment to quality. A reputable service will typically involve an initial consultation to understand the roll type, operating speed, required balance tolerance, and any historical issues. The actual service should include detailed documentation of the 'as found' imbalance condition, the correction method applied, the final 'as left' balance condition, and any relevant observations or recommendations. This documentation is invaluable for tracking roll performance and planning future maintenance. Furthermore, a good service provider will use properly calibrated equipment and adhere to relevant industry standards (like ISO 1940-1) for evaluating balance quality. They should also be able to offer advice on preventative measures to reduce the likelihood of future imbalance, such as recommending cleaning schedules for rolls prone to buildup. Don't hesitate to ask potential providers about their quality control procedures, their experience with your specific type of rolls, and their typical turnaround times.

Partnering for Performance: Choosing the Right Provider for Industrial Roll Dynamic Balancing

Selecting the right partner for something as critical as industrial roll dynamic balancing, particularly for precision paper and converting applications, requires careful consideration of several factors. Experience is paramount – look for a provider with a proven track record in balancing rolls of similar size, weight, and operating speed to yours. Their technicians should possess deep knowledge of dynamic balancing principles and practical experience with various roll constructions common in paper machines and converting lines. The quality and capability of their balancing equipment are also crucial; ensure they have machines that can handle your largest rolls and achieve the required balance tolerances. Certifications or adherence to quality management systems can provide additional assurance of their process reliability. Furthermore, consider their customer support and responsiveness. When a critical roll develops an issue, you need a provider who can respond quickly and effectively to minimize downtime. Choosing wisely means partnering with a team that understands the nuances of your industry and is equipped to deliver precision service consistently, ensuring your investment in paper roll balancing service provides maximum return.

Maximizing Uptime and Quality: The ROI of Expert Paper Roll Balancing Service

Investing in professional paper roll balancing service delivers significant returns on investment, often far outweighing the cost of the service itself. The most immediate and quantifiable benefit is the reduction or elimination of harmful vibration. This directly translates to extended machine life, particularly for bearings and other wear components. By reducing stress on these parts, you significantly decrease the frequency of unexpected failures and extend the intervals between planned maintenance, leading to substantial savings on repair costs and replacement parts. Reduced vibration also lowers noise levels in the workplace, contributing to a safer and more comfortable environment for operators. Frankly speaking, proactive balancing is a form of preventative maintenance that pays dividends by preserving your valuable capital equipment.

Beyond equipment longevity, properly balanced rolls dramatically improve operational efficiency and product quality. With vibration minimized, machines can often operate at higher speeds without performance degradation or increased risk of web breaks. This directly increases throughput and productivity. Stable roll operation leads to consistent web tension, better tracking, and improved process control, which in turn reduces scrap rates and improves the overall quality of the finished product, whether it's a printed sheet, a wound roll of paper, or a laminated film. Think of the costs associated with downtime and scrapped material – these can easily eclipse the cost of balancing. Many experts agree that investing in quality converting roll balancing or paper machine roll vibration analysis is a smart strategy to maximize uptime, minimize waste, and ensure competitive product quality. What kind of impact would a 5% reduction in scrap or a 10% increase in operational speed have on your bottom line?

Implementing a proactive approach to roll maintenance that includes regular inspection and balancing is a powerful way to leverage the benefits discussed. Instead of waiting for vibration to become noticeable or for a bearing to fail, consider vibration analysis as part of your routine preventative maintenance. This can help identify rolls that are starting to go out of balance before they cause significant problems. By planning for paper roll balancing service during scheduled downtime, you can avoid costly emergency repairs and maximize machine availability. Our company understands the critical role that balanced rolls play in your operations. We offer comprehensive roll balancing services designed to address the specific needs of the paper, printing, packaging, and converting industries, utilizing advanced techniques and equipment to restore your rolls to optimal condition and help you achieve peak performance and reliability from your machinery.

In conclusion, the importance of a professional paper roll balancing service cannot be overstated for industries relying on high-speed roll-based processes. From preventing costly machine damage and reducing maintenance expenses to improving product quality and increasing operational efficiency, the benefits are clear and tangible. Ignoring roll imbalance is like allowing a slow leak to damage the foundation of your operation. By partnering with experienced professionals equipped with the right technology, you ensure your rolls run smoothly, your machines last longer, and your production output meets the highest standards. Don't let hidden vibration costs erode your profitability. Take the necessary steps to evaluate the condition of your critical rolls and proactively schedule expert balancing services. The peace of mind that comes with knowing your machinery is running optimally, coupled with the significant long-term savings and quality improvements, makes professional paper roll balancing service a truly worthwhile investment.

For more detailed information, please visit our official website: paper roll balancing service