The Hidden Enemy: Roll Vibration

Roll vibration may seem like a minor issue, but it can significantly affect the lifespan of a paper machine. To be honest, it's worth noting that even subtle vibrations can lead to excessive wear and tear, ultimately reducing the machine's efficiency and longevity.

Understanding the Causes

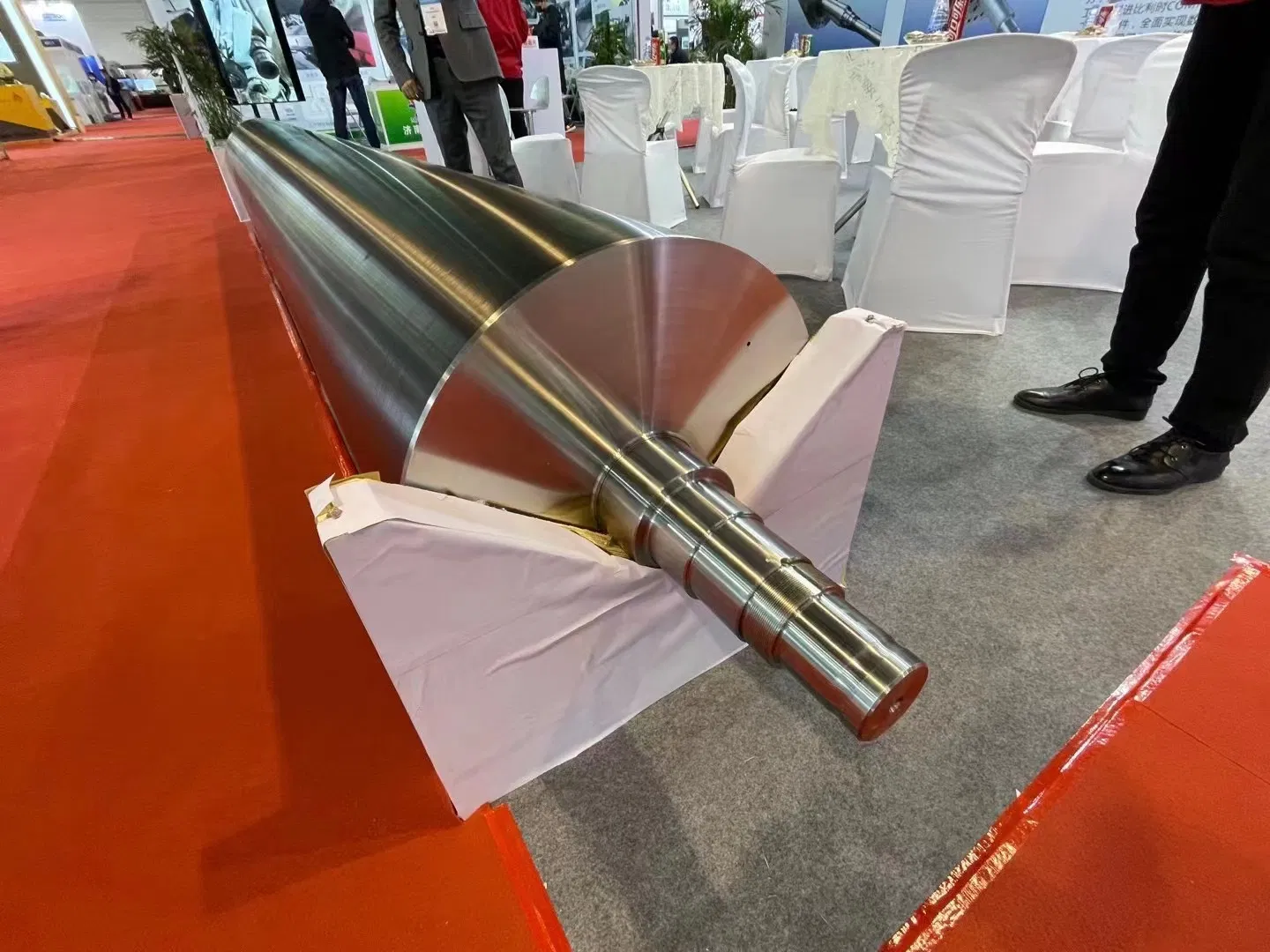

So, what causes roll vibration in the first place? Interestingly enough, there are several factors at play. These can include unbalanced rolls, misaligned bearings, or even issues with the drive system. It's crucial to identify the root cause to implement an effective solution.

The Devastating Effects on Paper Machine Longevity

If left unchecked, roll vibration can wreak havoc on paper machines. For starters, it can lead to increased stress on various components, resulting in premature failure. Moreover, the constant shaking can cause paper quality issues, leading to more waste and higher production costs.

How Imbalance Accelerates Wear and Tear

Have you ever wondered how something as simple as imbalance can cause so much damage? Well, when a roll is out of balance, it creates a centrifugal force that can lead to significant vibration. This, in turn, causes excessive wear on bearings, seals, and other critical parts.

Strategies to Minimize Roll Vibration

The good news is that there are practical steps you can take to minimize roll vibration. Regular maintenance and inspections are key, as they can help identify potential issues before they become major problems.

- Regular Roll Balancing: Ensuring your rolls are properly balanced can significantly reduce vibration levels.

- Precision Alignment: Properly aligning bearings and other components can also help mitigate vibration.

- Upgrading Components: In some cases, upgrading to more robust components can better withstand the rigors of the paper-making process.

The Role of Predictive Maintenance

Predictive maintenance plays a crucial role in minimizing roll vibration. By monitoring machine performance and identifying trends, you can predict potential issues and address them proactively. This approach not only extends the life of your paper machine but also reduces downtime and increases productivity.

How We Can Help

At our company, we specialize in helping businesses optimize their paper machines for maximum longevity and performance. Our team of experts can help identify sources of roll vibration and recommend effective solutions tailored to your specific needs. From regular maintenance to component upgrades, we've got you covered.

Conclusion

In conclusion, roll vibration is a significant factor that can impact the longevity of paper machines. By understanding its causes and implementing effective strategies to minimize it, you can extend the life of your equipment and improve your bottom line. As always, prevention is better than cure, so don't wait until it's too late to address roll vibration issues.

For more detailed information, please visit our official website: Roll vibration