The Evolution of Roll Surface Refinishing

In the ever-evolving world of roll manufacturing, surface refinishing has become a crucial aspect of ensuring optimal product quality and longevity. As it turns out, the refinishing process plays a significant role in the performance and durability of rolls used in various industries. Over the years, advanced techniques have emerged to address the growing demand for superior roll surface finishes. In this article, we delve into these innovative methods and explore their applications and benefits.

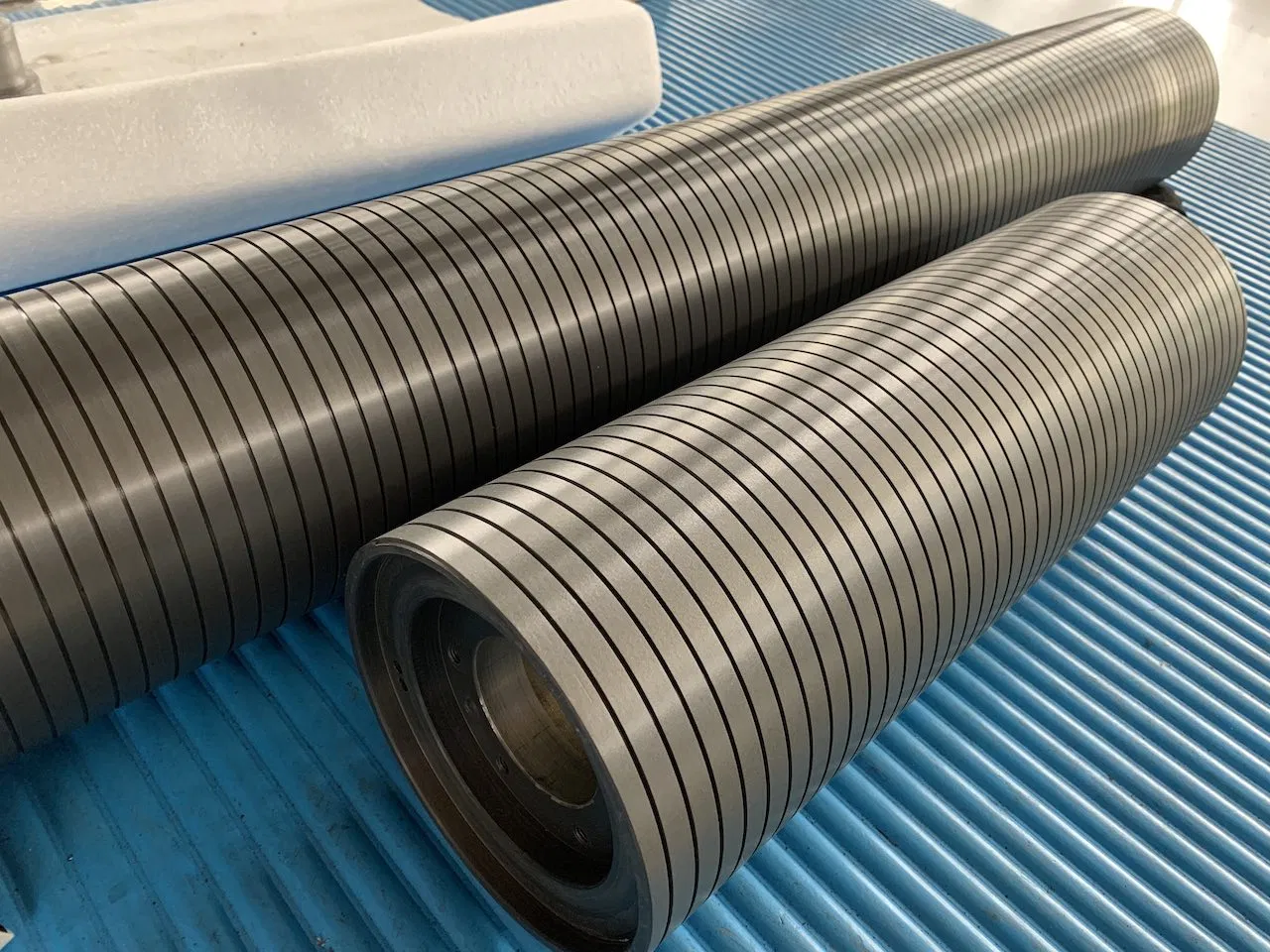

The Importance of Surface Finish

Before diving into the advanced techniques for roll surface refinishing, it's essential to understand why surface finish matters. Here's the thing: the quality of a roll's surface finish directly impacts its functionality and lifespan. A smoother, more uniform surface reduces friction, minimizes wear and tear, and enhances the roll's ability to transfer materials effectively. This is particularly important in industries such as paper and printing, metal processing, and plastics manufacturing, where roll performance can significantly impact product quality and production efficiency.

Advanced Techniques for Roll Surface Refinishing

With the importance of surface finish established, let's explore some of the advanced techniques that have transformed the roll surface refinishing process:

1. Laser Texturing

Laser texturing is an innovative approach that involves using lasers to create precise micro-patterns on the roll surface. This technique enhances the roll's ability to grip and transfer materials, improving product quality and reducing waste. Interestingly enough, laser texturing can be customized to suit specific applications, allowing for tailored solutions that cater to unique industrial requirements.

2. Electroplating

Electroplating is a surface refinishing method that involves depositing a thin layer of metal onto the roll's surface. This process not only enhances the roll's durability but also improves its heat and corrosion resistance. The choice of metal used in electroplating depends on the roll's intended application, with options such as chrome, nickel, and copper providing varying benefits.

3. Diamond Burnishing

Diamond burnishing is a technique that uses diamond-tipped tools to smooth and polish the roll surface. This process results in a mirror-like finish that significantly reduces friction and wear, extending the roll's lifespan. Diamond burnishing is particularly effective for rolls used in high-precision applications, where surface uniformity is crucial.

4. Thermal Spray Coating

Thermal spray coating involves applying a protective layer of material to the roll surface using a heat source. This method enhances the roll's resistance to wear, corrosion, and heat, making it ideal for use in harsh industrial environments. Thermal spray coatings can be made from various materials, including metals, ceramics, and polymers, to suit specific application requirements.

Practical Applications of Advanced Roll Surface Refinishing Techniques

Now that we've explored some advanced techniques for roll surface refinishing let's discuss their practical applications:

- Improving print quality in the paper and printing industry by reducing ink splatter and enhancing ink transfer

- Enhancing metal processing capabilities by improving roll grip and reducing friction

- Minimizing waste and increasing efficiency in plastics manufacturing by ensuring consistent material transfer

Choosing the Right Roll Surface Refinishing Technique

When selecting a roll surface refinishing technique, it's essential to consider the roll's intended application, the desired surface finish, and the specific benefits each method offers. In many cases, a combination of techniques may be required to achieve the optimal surface finish. Consulting with an experienced roll manufacturing and refinishing company can help ensure the best possible results.

The Future of Roll Surface Refinishing

As technology continues to evolve, so too will the techniques used in roll surface refinishing. Advances in materials science, automation, and process control are expected to drive further innovation in this field, with new methods and applications emerging to meet the ever-changing demands of industry. By staying informed and embracing these advancements, manufacturers can ensure their rolls continue to deliver optimal performance and reliability.

In Conclusion

Roll surface refinishing is an essential aspect of roll manufacturing, with advanced techniques playing a crucial role in enhancing product quality and longevity. By understanding the importance of surface finish and exploring the latest refinishing methods, manufacturers can make informed decisions that ultimately benefit their operations and bottom line. To learn more about advanced roll surface refinishing techniques and how they can be applied to your specific needs, consult with our team of experts today.

For more detailed information, please visit our official website: