In the fast-paced world of paper manufacturing, where demand is ever-increasing and competition is fierce, the pursuit of operational efficiency is not merely a goal, but a necessity for survival and prosperity. At the heart of any successful paper mill lies the intricate machinery, and within this machinery, paper-making rolls stand out as critical components. These rolls, often unseen and underappreciated, are the unsung heroes of paper production, directly influencing the quality, speed, and overall efficiency of the entire process. Investing in high-quality paper-making rolls is not just an expenditure; it's a strategic decision that yields substantial returns in terms of optimized production, reduced downtime, and enhanced product quality. This article delves into the multifaceted ways in which high-quality paper-making rolls contribute to maximizing efficiency in paper manufacturing, exploring their design, materials, maintenance, and the tangible benefits they bring to the table. We will explore how choosing the right rolls can transform your paper production from a good operation into a truly exceptional and highly efficient one.

Understanding the Critical Role of Paper-Making Rolls

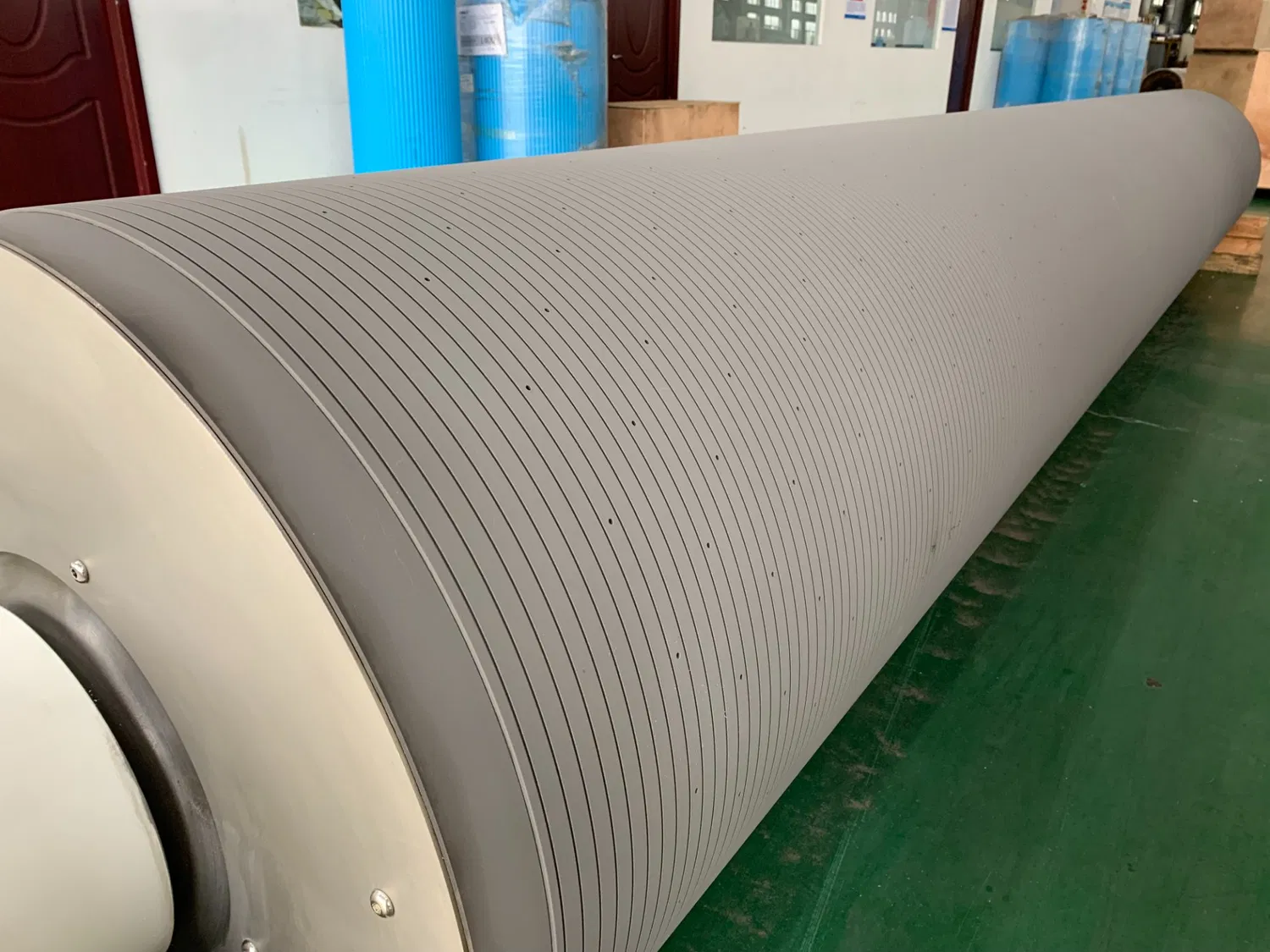

To truly appreciate the impact of high-quality paper-making rolls on efficiency, it's essential to first understand their diverse functions within the paper production process. Paper-making is a complex series of operations, from pulp preparation to the final winding of paper reels, and rolls are involved in virtually every stage. Press rolls, for instance, are crucial for dewatering the paper web, squeezing out excess water to consolidate the fibers. Dryer rolls, on the other hand, utilize heat to further remove moisture and ensure the paper achieves the desired dryness and strength. Guide rolls, as the name suggests, are responsible for precisely guiding the paper web through the machine, preventing wrinkles, breaks, and misalignments. Each type of roll, whether it's a breast roll, couch roll, calendar roll, or reel spool, plays a distinct and indispensable role in shaping the characteristics of the final paper product. The performance of each roll directly impacts the speed at which paper can be produced, the uniformity of the paper's properties, and the overall smoothness and reliability of the production line. Therefore, understanding the specific demands placed on each type of roll is the first step in appreciating how quality becomes a paramount factor in achieving maximum efficiency.

The Direct Impact of Roll Quality on Production Efficiency

The link between roll quality and production efficiency is not just theoretical; it's a practical reality felt on the mill floor every day. Low-quality or worn-out rolls can become significant bottlenecks in the production process, leading to a cascade of inefficiencies. For example, rolls with uneven surfaces or poor material properties can cause inconsistent pressing or drying, resulting in paper with uneven thickness, moisture content, or surface finish. This, in turn, can lead to increased waste due to rejected paper, slower machine speeds to compensate for inconsistencies, and higher energy consumption to over-dry or re-process substandard paper. Furthermore, inferior rolls are more prone to breakdowns and require more frequent maintenance or replacement, leading to costly downtime. Every hour of downtime translates directly into lost production and revenue. Conversely, high-quality rolls, engineered with precision and built from superior materials, offer consistent and reliable performance. They ensure uniform pressure and temperature distribution, leading to consistent paper quality, reduced waste, faster machine speeds, and less frequent interruptions. In essence, investing in quality rolls is an investment in operational uptime and consistent, high-volume output, the very definition of efficiency.

Material Science: The Foundation of High-Performance Rolls

The exceptional performance and longevity of high-quality paper-making rolls are deeply rooted in the science of materials. The materials used in roll construction dictate their strength, durability, resistance to wear and corrosion, and their ability to withstand the demanding conditions of paper production. For instance, press rolls often require materials with excellent water resistance and compressive strength to effectively remove water from the paper web under high pressure. Dryer rolls, on the other hand, need materials with high thermal conductivity to efficiently transfer heat and materials that can withstand elevated temperatures without deformation or degradation. Common materials include various grades of steel, each chosen for specific properties like hardness, tensile strength, and corrosion resistance. More advanced materials, such as composite materials or specialized alloys, are increasingly being used to address specific challenges, like reducing roll weight, improving vibration damping, or enhancing resistance to harsh chemicals. The selection of the right material is a critical engineering decision, balancing performance requirements, cost considerations, and the specific operating environment of the roll. High-quality roll manufacturers invest heavily in material research and testing to ensure their rolls are not just adequate, but optimized for peak performance and extended service life, directly contributing to efficiency gains.

Precision Engineering and Design for Optimal Efficiency

Beyond material selection, the design and engineering of paper-making rolls play a crucial role in maximizing efficiency. Modern roll manufacturing employs advanced engineering principles and precision machining techniques to create rolls that are not only robust but also optimized for specific functions. Roll geometry, for example, is carefully calculated to ensure uniform pressure distribution across the paper web, preventing uneven pressing or drying. Crown profiles, a subtle curvature applied to the roll surface, are engineered to compensate for roll deflection under load, ensuring consistent nip pressure across the width of the machine. Surface finishes are also meticulously controlled, ranging from smooth, polished surfaces for certain applications to textured or grooved surfaces for others, each designed to optimize friction, water removal, or heat transfer. Furthermore, internal roll design, including features like cooling channels or internal structures for weight reduction, are engineered to enhance performance and reduce energy consumption. The integration of sensors and monitoring systems into modern rolls allows for real-time performance analysis and proactive maintenance, further contributing to efficiency by preventing unexpected failures and optimizing operating parameters. This focus on precision engineering and design is what distinguishes high-quality rolls and unlocks their full potential for efficiency enhancement.

Maintenance Strategies for Sustaining Roll Efficiency and Longevity

Even the highest quality paper-making rolls require regular maintenance to sustain their optimal performance and efficiency over their operational lifespan. A proactive and well-planned maintenance strategy is not just about extending the life of the rolls; it's about ensuring they continue to operate at peak efficiency, minimizing downtime, and preventing costly failures. Regular inspections are crucial to identify early signs of wear, damage, or imbalance. This can include visual inspections for surface defects, dimensional checks for wear or deformation, and vibration analysis to detect imbalances or bearing issues. Cleaning is another essential aspect of maintenance, removing pulp buildup, contaminants, or corrosion products that can affect roll performance and paper quality. Roll grinding and resurfacing are periodic procedures to restore the roll surface profile, remove wear or damage, and maintain the required surface finish. Lubrication of bearings and other moving parts is critical to prevent friction, wear, and premature failure. Implementing a computerized maintenance management system (CMMS) can help track roll history, schedule maintenance tasks, and analyze performance data to optimize maintenance intervals and strategies. By investing in diligent and timely maintenance, paper mills can ensure their high-quality rolls deliver consistent efficiency and a maximum return on investment for years to come.

Real-World Examples: Efficiency Gains with High-Quality Rolls

The benefits of using high-quality paper-making rolls are not just theoretical promises; they are demonstrated in tangible results across numerous paper mills worldwide. Consider a case study where a mill struggling with frequent web breaks and inconsistent paper quality decided to upgrade their press section rolls to high-performance composite rolls. The result was a significant reduction in web breaks, leading to increased machine uptime and a substantial boost in production volume. In another instance, a mill experiencing high energy consumption in their dryer section replaced their conventional dryer rolls with advanced, thermally efficient rolls. This resulted in a noticeable decrease in energy consumption per ton of paper produced, contributing to significant cost savings and a reduced environmental footprint. Many mills have also reported improved paper quality, with more uniform thickness, smoother surfaces, and better printability after upgrading to high-quality rolls. These real-world examples highlight the practical and measurable impact of investing in quality rolls. While the initial investment may be higher, the long-term gains in terms of increased production, reduced waste, lower energy consumption, and improved product quality far outweigh the upfront costs. It's a strategic investment that pays dividends in sustained efficiency and profitability.

Our Commitment to Optimizing Your Paper Production Efficiency

At our company, we understand the critical role that high-quality paper-making rolls play in achieving optimal efficiency in paper production. We are dedicated to providing our customers with state-of-the-art rolls engineered for superior performance, durability, and reliability. Our rolls are manufactured using premium materials, advanced engineering design, and stringent quality control processes. We offer a comprehensive range of rolls, tailored to meet the specific demands of various paper-making applications, from press rolls and dryer rolls to guide rolls and calendar rolls. Our engineering team works closely with our clients to understand their unique needs and challenges, providing customized roll solutions designed to maximize their production efficiency and product quality. We also offer expert technical support, including installation assistance, maintenance training, and performance monitoring, to ensure our customers get the most out of their investment. We believe that by partnering with us, paper mills can unlock significant efficiency gains, reduce operational costs, and enhance their competitive edge in the demanding paper market. Our commitment is to be your trusted partner in achieving paper production excellence through high-quality, high-performance paper-making rolls.

Conclusion: Investing in Quality Rolls for a Sustainable Future

In conclusion, maximizing efficiency in paper production is not merely about incremental improvements; it's about embracing strategic investments that yield transformative results. High-quality paper-making rolls are undoubtedly one such investment. They are not just components; they are enablers of efficiency, driving down costs, boosting productivity, and enhancing product quality. By choosing rolls engineered with superior materials, precision design, and a focus on longevity, paper mills can unlock significant operational advantages. Reduced downtime, minimized waste, lower energy consumption, and improved paper quality are all tangible benefits that directly contribute to a more sustainable and profitable paper production operation. As the paper industry continues to evolve and face new challenges, the pursuit of efficiency will become even more critical. Investing in high-quality paper-making rolls is not just a smart business decision today; it's a forward-thinking strategy for ensuring long-term success and sustainability in the years to come. It's about recognizing that the seemingly simple roll is, in fact, a powerful lever for maximizing efficiency and shaping the future of paper manufacturing.

For more detailed information, please visit our official website: paper-making rolls