Paper, a ubiquitous material in our daily lives, is produced by sophisticated machinery. Have you ever wondered how that crisp sheet in your printer or the cardboard box holding your online order comes to be? Understanding the papermaking process begins with knowing the two fundamental types of papermaking machines: the Fourdrinier machine and the Cylinder machine. This article will delve into the intricacies of both, exploring their unique characteristics and highlighting their respective roles in the paper industry.

The Fourdrinier Machine: A Workhorse of the Industry

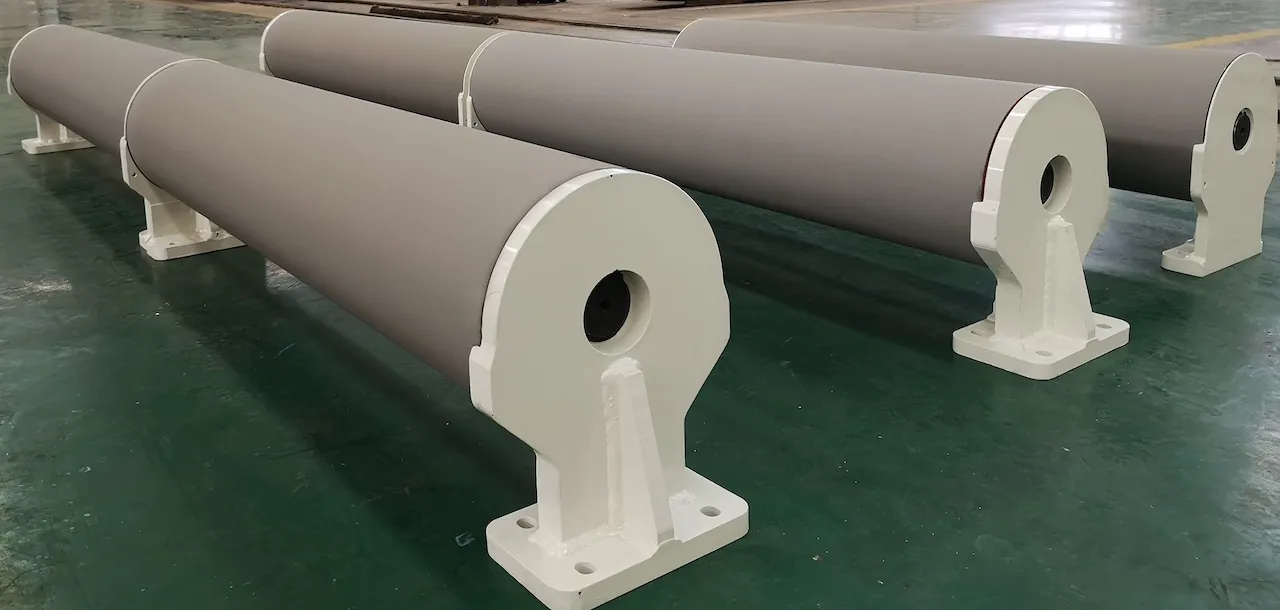

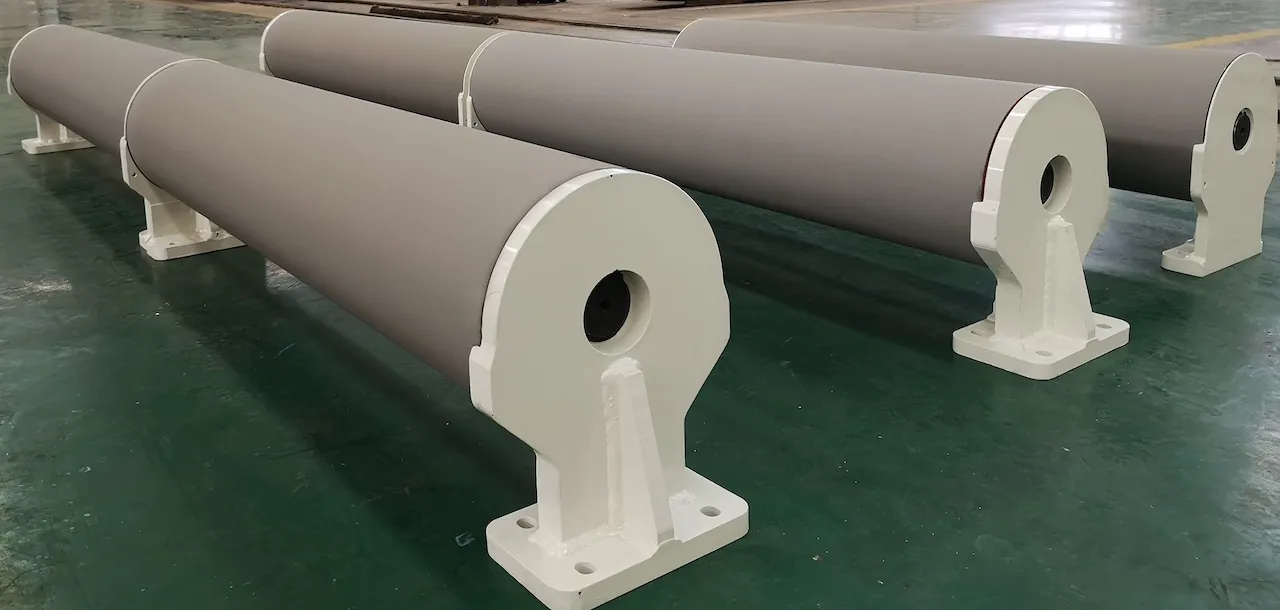

The Fourdrinier machine, named after its 19th-century developers, the Fourdrinier brothers, is the dominant player in the papermaking world. This complex system utilizes a moving wire mesh to form a continuous web of paper. The process begins with a slurry of pulp, a mixture of water and wood fibers, being deposited onto the continuously moving wire. As the water drains through the mesh, a thin layer of interwoven fibers begins to form. This nascent paper web then travels through a series of rollers and dryers, where excess water is removed, and the paper is pressed and smoothed. The Fourdrinier machine’s ability to produce a continuous sheet of paper makes it ideal for high-volume production of various paper grades, from printing paper to packaging materials. What makes this machine so versatile? Its adaptable design allows for modifications and adjustments to create specific paper properties, catering to a wide range of applications.

The Cylinder Machine: Crafting Specialty Papers

While the Fourdrinier machine reigns supreme in volume, the Cylinder machine holds its own niche in the world of papermaking. Employing a series of rotating cylinders covered with wire mesh, this machine forms the paper sheet layer by layer. The pulp is drawn onto the cylinder's surface as it rotates in a vat of pulp. Each cylinder adds a layer, building up the desired thickness and creating a multi-ply structure. This unique process allows for the production of thicker and more textured papers, including specialty papers like cardboard, tissue paper, and heavy-duty packaging materials. The cylinder machine's strength lies in its capacity to produce multi-ply paperboard, a key material in packaging and construction. Think of the corrugated cardboard box – it's likely a product of the cylinder machine.

Key Differences and Applications: Fourdrinier vs. Cylinder

Understanding the core differences between these two types of papermaking machines is crucial for appreciating their individual strengths. Fourdrinier machines excel at producing thinner, smoother papers at high speeds, making them ideal for printing and writing papers, newsprint, and some packaging papers. Cylinder machines, on the other hand, specialize in thicker, multi-ply products like cardboard, tissue, and specialty papers requiring specific textures. The choice between these two types of papermaking machines hinges on the desired end product and the required production scale.

Exploring the Paper Manufacturing Process: A Deeper Dive

Both the Fourdrinier and Cylinder machines contribute significantly to the overall paper manufacturing process. The process extends beyond the machine itself, encompassing pulp preparation, stock refining, and various finishing treatments. Pulp preparation involves breaking down wood chips or recycled paper into fibers. Stock refining further processes these fibers, influencing the final paper properties. After the paper web is formed on either machine, it undergoes a series of drying and calendering processes to achieve the desired smoothness and finish.

Modern Advancements in Papermaking Machines

The world of papermaking is constantly evolving. Modern advancements are pushing the boundaries of both Fourdrinier and Cylinder machines, enhancing efficiency and product quality. Automation and computer control systems are increasingly integrated, allowing for precise control over various parameters like paper thickness, moisture content, and surface properties. These innovations optimize production speed, minimize waste, and enable the creation of increasingly specialized paper products.

Sustainability in Papermaking: A Growing Focus

With growing environmental awareness, sustainability is becoming a central concern in the paper industry. Both Fourdrinier and Cylinder machine manufacturers are incorporating sustainable practices into their designs. This includes utilizing recycled fibers, reducing water consumption, and implementing energy-efficient technologies. The future of papermaking relies on balancing production efficiency with environmental responsibility. So, the next time you pick up a piece of paper, consider the intricate process and the machines behind its creation.

Choosing the Right Papermaking Machine: Factors to Consider

So, you're considering investing in a papermaking machine? What factors should influence your decision? The type of paper you intend to produce, your desired production capacity, and your budget are all crucial considerations. Consult with industry experts to determine the most suitable machine for your specific needs. A thorough assessment of your requirements will guide you towards the optimal choice, whether it's the versatile Fourdrinier or the specialized Cylinder machine.

Troubleshooting Common Papermaking Machine Issues

Like any complex machinery, papermaking machines can encounter operational challenges. Common issues include web breaks, inconsistencies in paper thickness, and variations in surface quality. Proper maintenance, regular inspections, and operator training are essential for minimizing downtime and ensuring consistent product quality. Effective troubleshooting and preventative measures are key to maintaining optimal performance.

The Future of Papermaking Machines: Innovation and Adaptation

The papermaking industry is poised for continued innovation. Developments in materials science, automation, and digital technologies are driving advancements in both Fourdrinier and Cylinder machine designs. These advancements promise to further enhance efficiency, improve product quality, and promote sustainable practices within the papermaking sector. What advancements do you anticipate seeing in the future?

Next Steps: Exploring Papermaking Machinery Further

This article provided a comprehensive overview of the two main types of papermaking machines. To delve deeper into this fascinating field, explore online resources, industry publications, and connect with papermaking equipment manufacturers. Understanding the nuances of these machines is crucial for anyone involved in the paper industry or simply curious about the origins of this everyday material.