Roll grinding and refurbishment are essential maintenance procedures for industries relying on high-precision rollers, such as printing, paper manufacturing, converting, and metal processing. Implementing best practices in these processes is crucial for maintaining product quality, minimizing downtime, and extending the lifespan of your valuable rolls. This guide explores the key steps and considerations for achieving optimal results in roll grinding and refurbishment.

Inspection and Assessment: The Foundation of Effective Refurbishment

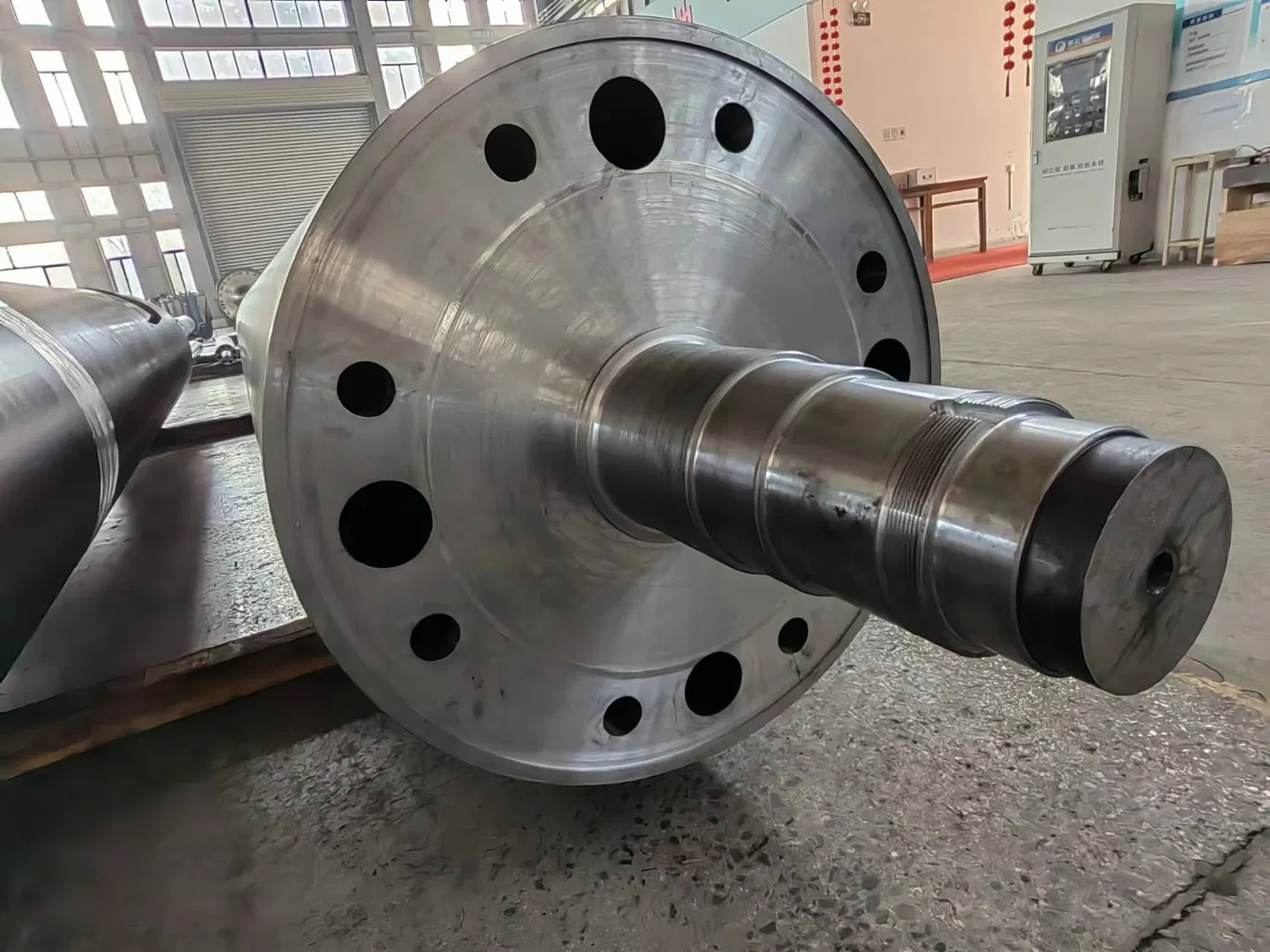

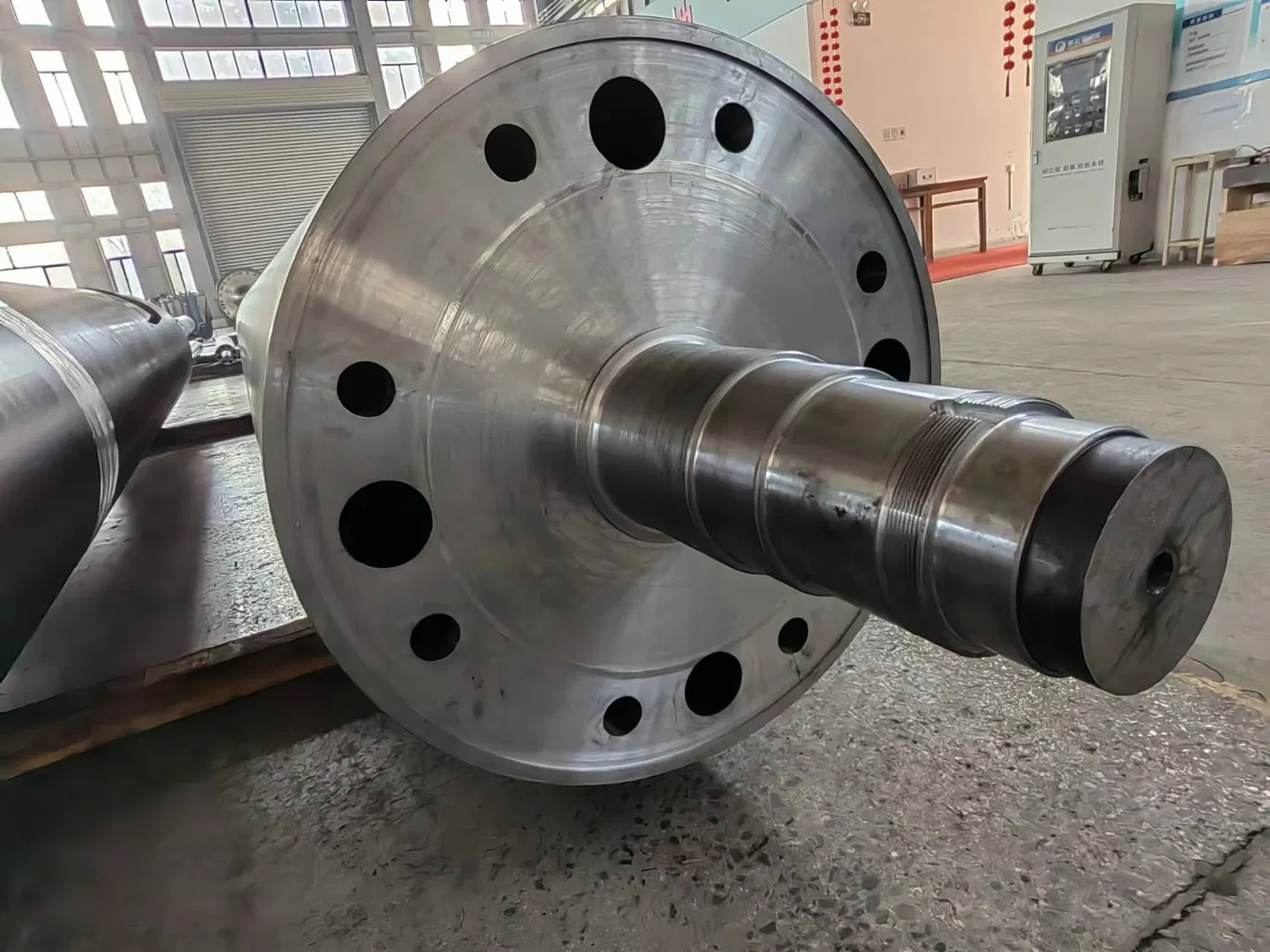

Before initiating any grinding or refurbishment work, a thorough inspection of the roll's condition is paramount. This involves visually examining the roll surface for defects like cracks, spalls, and corrosion. Accurate measurements of roll diameter, roundness, and surface roughness are also critical. This assessment helps determine the extent of the damage and guides the selection of the appropriate repair strategy. Don't underestimate this initial step – a precise diagnosis is key to a successful refurbishment.

Choosing the Right Grinding Process

The selection of the grinding process depends on the roll material, the severity of the damage, and the desired surface finish. Common methods include conventional grinding, CNC grinding, and superfinishing. CNC grinding, for instance, offers high precision and repeatability, making it ideal for complex roll profiles. Consider the specific requirements of your application when making this decision. What level of precision is necessary for your operation?

Effective Refurbishment Strategies: Beyond Grinding

Roll refurbishment often involves more than just grinding. Depending on the roll’s condition, other techniques like thermal spraying, welding, or plating might be necessary. Thermal spraying, for example, can restore worn or damaged areas by depositing a thin layer of protective coating. These additional refurbishment techniques can significantly extend the roll's service life and restore its optimal performance.

Roll Grinding and Refurbishment: Material Considerations

Different roll materials require different grinding and refurbishment approaches. For example, hardened steel rolls demand specialized grinding wheels and techniques to prevent overheating and damage. Understanding the specific properties of your roll material is crucial for selecting the appropriate procedures and achieving optimal results. Have you considered the specific needs of your roll material in your current maintenance strategy?

Minimizing Downtime: Efficient Roll Management

Efficient roll management is crucial for minimizing downtime and maximizing productivity. This involves scheduling regular inspections and preventative maintenance, as well as having spare rolls readily available. A proactive approach to roll maintenance can prevent unexpected failures and costly production delays.

Cost Optimization: Balancing Quality and Budget

While roll grinding and refurbishment represent an investment, they are significantly more cost-effective than replacing entire rolls. By adhering to best practices and partnering with experienced service providers, you can optimize the cost of these essential maintenance procedures without compromising quality. Proper maintenance ultimately leads to long-term cost savings.

Roll Life Extension: The Benefits of Proactive Maintenance

Implementing a comprehensive roll maintenance program, encompassing regular inspections, grinding, and refurbishment, is essential for extending roll life. Proactive maintenance not only reduces the frequency of costly repairs but also ensures consistent product quality and minimizes downtime.

Choosing the Right Partner: Expertise and Experience Matter

Selecting a qualified and experienced service provider for your roll grinding and refurbishment needs is paramount. Look for a partner with a proven track record, advanced equipment, and a deep understanding of your specific industry requirements. Their expertise can make a significant difference in the quality and longevity of your rolls.

Roll Grinding and Refurbishment: A Continuous Improvement Process

Regularly evaluating and refining your roll maintenance procedures is essential for continuous improvement. Tracking key performance indicators, such as roll lifespan and downtime, can help identify areas for optimization and ensure you're getting the most out of your rolls.

Next Steps: Implementing Best Practices

Take the first step towards optimizing your roll performance. Contact a reputable roll grinding and refurbishment specialist today to discuss your specific needs and develop a customized maintenance plan. Implementing these best practices will not only extend the lifespan of your rolls but also contribute to improved product quality, reduced downtime, and enhanced overall operational efficiency.