The Incredible Journey Begins: Granite Quarrying

Did you know that the story of granite roll manufacturing starts deep within the Earth? As it turns out, granite is an igneous rock formed from the slow cooling of magma beneath the surface. Mining this rock involves a process called quarrying, where large blocks of granite are extracted from the ground.

The Art of Granite Selection

Not all granite is created equal, especially when it comes to manufacturing high-quality rolls for paper machines. The ideal granite should have low porosity, high density, and exceptional resistance to wear and tear. This is why granite roll manufacturers carefully select their raw materials to ensure the best possible performance.

From Block to Roll: The Manufacturing Process

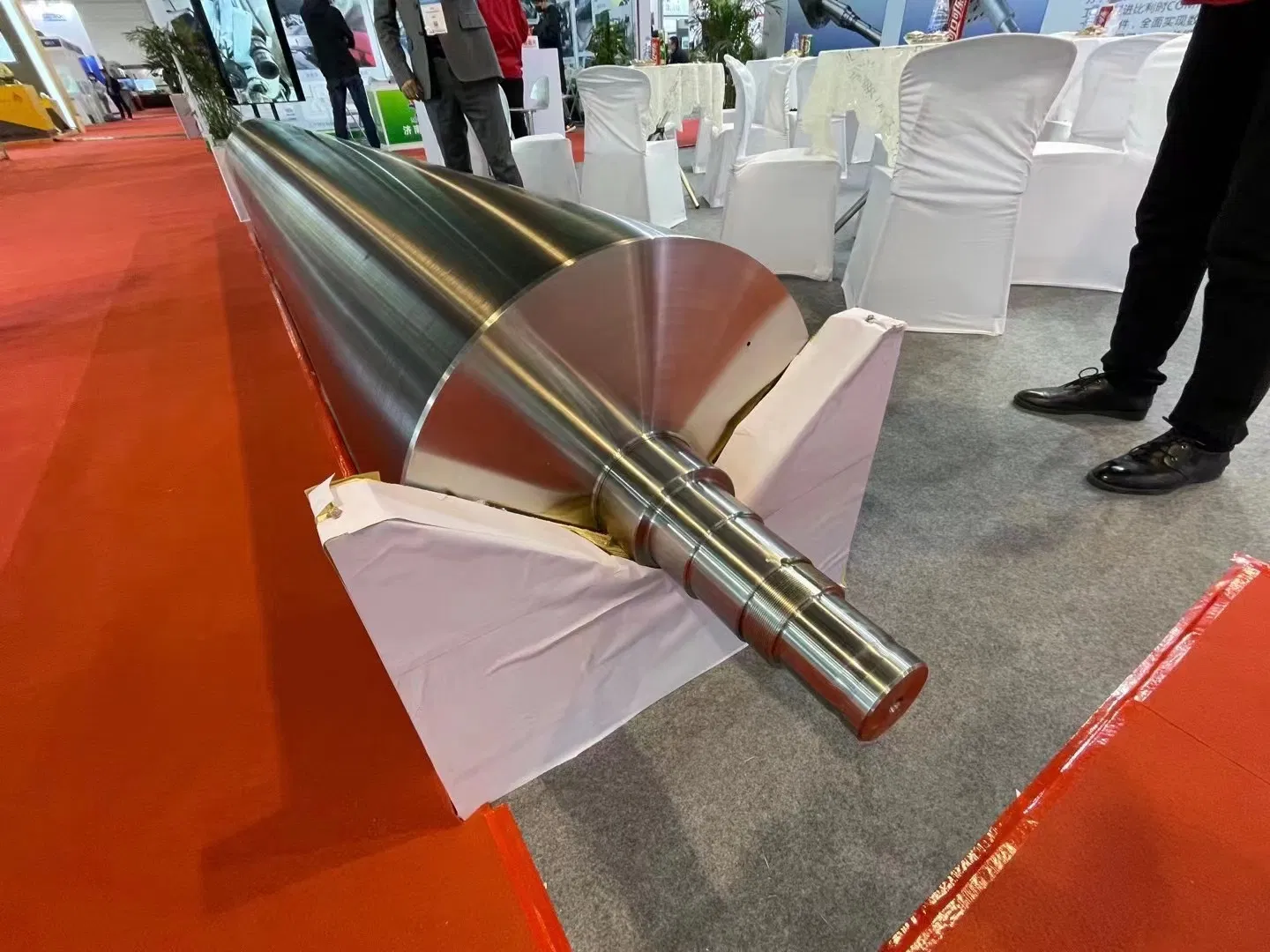

Once the perfect block of granite has been chosen, it's time to transform it into a roll. This intricate process involves several stages, including cutting, turning, grinding, and polishing. Each step requires precision and expertise to create a smooth, uniform roll that meets the stringent requirements of the paper industry.

Cutting and Turning

The first step in granite roll manufacturing is cutting the massive granite block into smaller, more manageable pieces. These pieces are then turned on a lathe to achieve the desired cylindrical shape. It's crucial to maintain tight tolerances during this stage to ensure the roll's accuracy and stability.

Grinding and Polishing

After the rough shape has been established, the granite roll undergoes a series of grinding and polishing operations. These processes gradually refine the surface, removing any imperfections and achieving the desired finish. The final product is a beautifully polished, mirror-like roll that's ready for installation in a paper machine.

The Crucial Role of Granite Rolls in Paper Machines

So, why are granite rolls so important in the paper-making process? Well, they serve several critical functions, including supporting the web of paper, applying pressure, and maintaining consistent temperature and moisture levels. The unique properties of granite make it an ideal material for these demanding applications.

Support and Pressure

As paper travels through the machine, it must be supported by a series of rolls to prevent sagging or wrinkling. Granite rolls provide excellent support due to their high density and rigidity. Additionally, they can apply precise pressure, which is essential for tasks like calendering or embossing.

Temperature and Moisture Control

Maintaining the correct temperature and moisture levels is crucial for producing high-quality paper. Granite's low thermal conductivity and minimal moisture absorption make it an excellent choice for regulating these factors. This helps ensure consistent paper quality and reduces waste.

Choosing the Right Granite Roll Manufacturer

When selecting a granite roll manufacturer, it's essential to consider their experience, expertise, and commitment to quality. Look for companies with a proven track record of producing reliable, high-performance rolls that meet your specific needs. Don't be afraid to ask questions and request references to ensure you're making the best possible choice.

Actionable Tips

In Conclusion: The Art and Science of Granite Roll Manufacturing

As we've seen, granite roll manufacturing is a complex and fascinating process that transforms raw granite into precision components essential for the paper industry. By understanding this journey and working with a reputable manufacturer, you can ensure your paper machine operates at peak efficiency, producing the highest quality paper possible.

So, the next time you hold a piece of paper in your hands, take a moment to appreciate the incredible journey it has taken – from the depths of a granite quarry to the smooth, uniform rolls that make its creation possible.