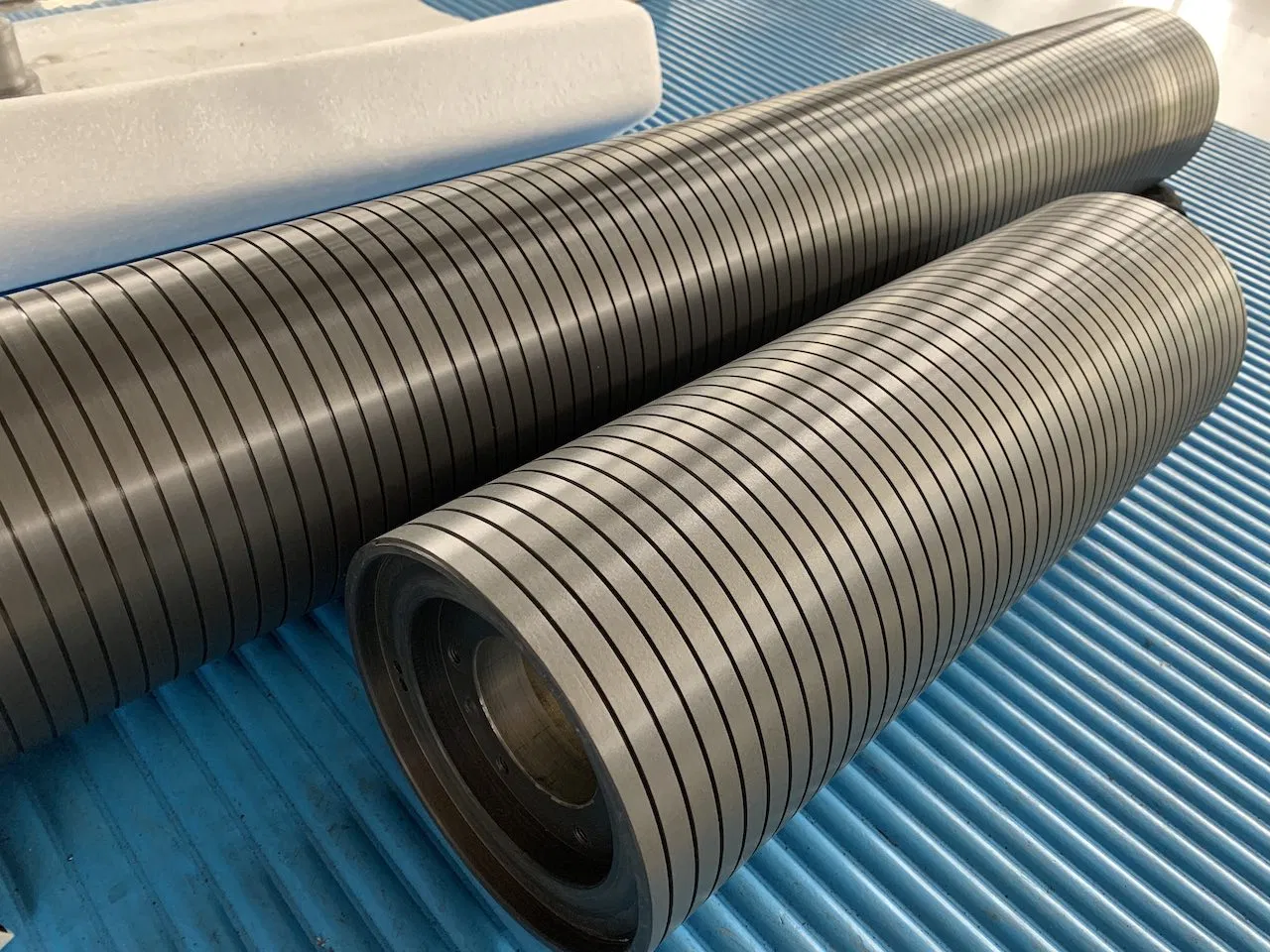

Introduction: The Role of Stone Rolls in Papermaking

Stone rolls play a crucial role in the papermaking process. They help create the desired paper texture, smoothness, and finish. However, they can encounter various issues that affect product quality and efficiency. Let's dive into some common problems and their solutions.

Uneven Paper Surface: The Art of Balancing

Have you ever noticed an uneven paper surface, with some areas appearing smoother than others? This issue is often caused by imbalanced stone rolls. The solution lies in regular maintenance and balancing of the rolls. By ensuring equal pressure across the entire roll surface, you'll achieve consistent paper texture.

Key Insight: Regular Roll Checkups

Regular inspections are essential to maintaining stone roll balance. Look for signs of wear, such as grooves or flat spots, and address them promptly. In my experience, scheduling monthly checkups can significantly improve paper quality and minimize downtime.

Excessive Wear: A Tale of Proper Lubrication

Excessive wear on stone rolls is another prevalent issue in papermaking. Interestingly enough, this problem often results from improper lubrication. Too much or too little lubricant can accelerate wear, leading to premature roll replacement. So, how do you strike the perfect balance?

Key Insight: The Power of Proper Lubrication

Many experts agree that using high-quality lubricants designed specifically for stone rolls can extend their lifespan. Moreover, establishing a consistent lubrication schedule can help maintain optimal performance. By following the manufacturer's recommendations and monitoring roll condition, you can reduce wear and save on replacement costs.

Contamination: The Importance of Cleanliness

Contamination is a common challenge in papermaking, and stone rolls are no exception. Debris, fibers, and other particles can accumulate on roll surfaces, causing defects in the final product. The good news is that regular cleaning can prevent these issues.

Key Insight: Keep It Clean

Incorporating daily cleaning routines into your maintenance schedule can significantly reduce contamination. Use appropriate cleaning solutions and tools to remove debris without damaging the roll surface. As it turns out, a clean roll is a happy roll!

Practical Application: Tips for Stone Roll Maintenance

Conclusion: The Path to Smoother Papermaking

Addressing common issues with stone rolls in papermaking can lead to improved product quality, increased efficiency, and reduced costs. By implementing regular maintenance routines and following best practices for lubrication and cleaning, you'll be well on your way to achieving smoother, more consistent paper production. So, what are you waiting for? It's time to roll up your sleeves and get started!