The Anatomy of Paper Machine Rolls

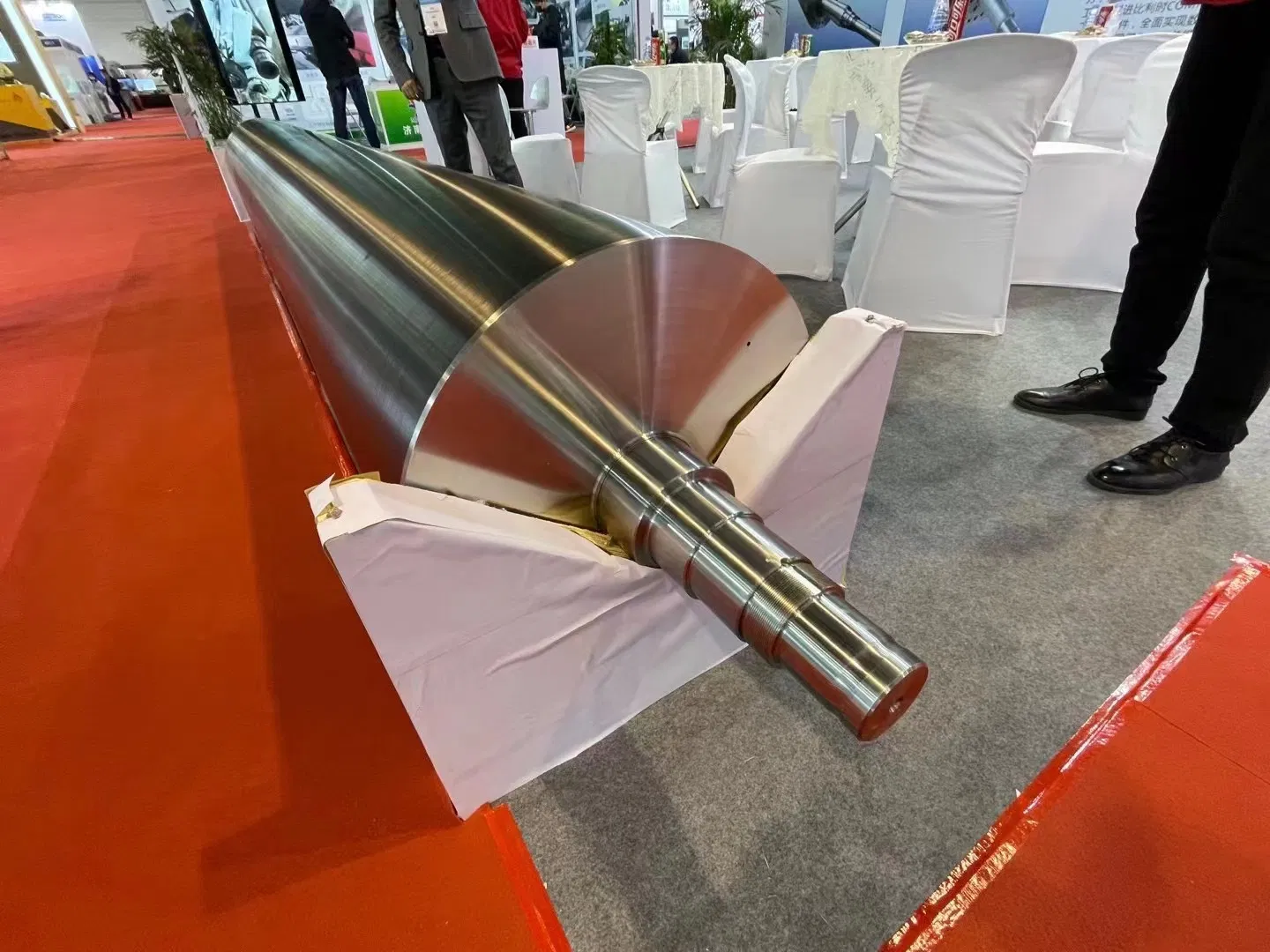

Paper machine rolls are essential components in the paper production process. These cylindrical rolls, made of metal or composite materials, play various roles in the papermaking process. The primary function of paper machine rolls is to guide, support, and control the web of paper material as it travels through the machine. Key components of a paper machine roll include the shell, the core, and the covering layer. The shell is typically made of steel and provides the roll's structural integrity. The core, often constructed from aluminum or steel, is responsible for maintaining the roll's shape and stiffness. The covering layer, usually composed of elastomeric materials like rubber or polyurethane, ensures optimal contact with the paper web and reduces wear and tear.

Factors Affecting Roll Performance

Several factors can impact the performance of paper machine rolls, including roll diameter, length, surface roughness, and hardness. Roll diameter and length can affect the roll's stiffness, while surface roughness and hardness influence the roll's ability to grip the paper web and minimize wear and tear. A roll's performance can also be affected by its operating temperature and speed. High temperatures can lead to increased wear and tear, while excessive speeds can cause vibrations and instability in the paper web. To optimize roll performance, it is essential to carefully consider these factors during the design and maintenance phases.

Roll Performance Analysis Techniques

Regular performance analysis is crucial for maintaining the efficiency and quality of paper production. Roll performance analysis techniques include visual inspections, vibration analysis, and roll profile measurements. Visual inspections can help identify signs of wear and tear, while vibration analysis can detect potential issues with roll balance and alignment. Roll profile measurements can assess the roll's surface characteristics and ensure optimal contact with the paper web. By employing these analysis techniques, paper manufacturers can proactively address performance issues, extend the lifespan of their rolls, and improve overall production efficiency.

Improving Roll Performance and Paper Quality

To enhance roll performance and paper quality, paper manufacturers can consider several strategies. These include selecting appropriate roll materials and coverings, optimizing roll design, and implementing regular maintenance schedules. Proper material selection can improve the roll's resistance to wear and tear, while optimized roll design can enhance stability and stiffness. Regular maintenance, including cleaning, lubrication, and surface reconditioning, can extend the roll's lifespan and ensure consistent performance. Additionally, investing in advanced roll technologies, such as grooved or patterned rolls, can further improve paper production efficiency and quality.

Conclusion

Understanding paper machine roll structure and performance analysis is critical for optimizing paper production efficiency and quality. By considering factors affecting roll performance and employing appropriate analysis techniques, paper manufacturers can proactively address performance issues, extend roll lifespan, and improve overall production processes. Ultimately, this leads to higher-quality paper products and increased profitability for the manufacturer.