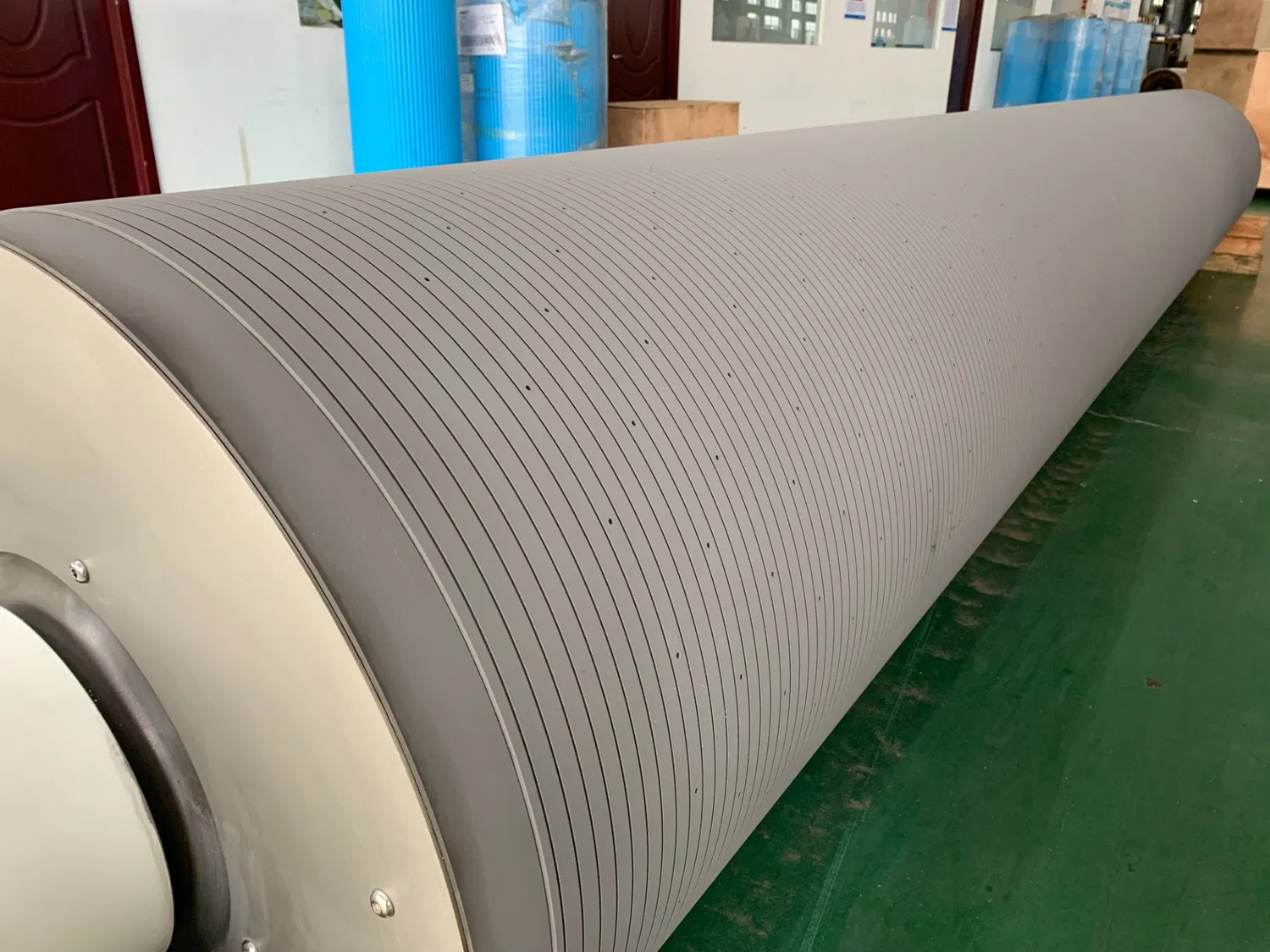

The Role of Industrial Rollers

Industrial rollers play a critical role in various manufacturing processes, from printing and packaging to material handling and processing. They are responsible for transferring materials, applying pressure, and providing support, among other functions. Over time, rollers can accumulate dirt, dust, and debris, which can affect their performance and longevity.

The Impact of Dirty Rollers

Dirty rollers can cause a variety of problems, including uneven material transfer, reduced product quality, and increased downtime due to equipment failure. In some cases, dirty rollers can also pose a safety hazard, as debris buildup can cause rollers to become unbalanced or misaligned.

The Benefits of Regular Roller Cleaning and Maintenance

Regular roller cleaning and maintenance can help prevent these issues and ensure optimal performance. By removing dirt, dust, and debris, you can improve material transfer, reduce wear and tear on equipment, and extend the lifespan of your rollers. Additionally, regular maintenance can help identify potential issues before they become major problems, allowing you to address them proactively and avoid costly repairs or replacements.

Best Practices for Roller Cleaning and Maintenance

There are several best practices for roller cleaning and maintenance. First, it is important to establish a regular cleaning and maintenance schedule based on the specific needs of your equipment and the environment in which it operates. This may involve daily, weekly, or monthly cleaning and maintenance tasks.

- Clean rollers using a mild detergent and soft brush or cloth to avoid damaging the surface.

- Inspect rollers for signs of wear, damage, or misalignment and address any issues promptly.

- Lubricate bearings and other moving parts to reduce friction and wear.

- Store rollers properly to prevent damage and contamination.

Conclusion

Regular roller cleaning and maintenance is essential for optimal industrial performance and equipment longevity. By following best practices and establishing a regular maintenance schedule, you can improve material transfer, reduce downtime, and extend the lifespan of your rollers. Remember to clean rollers using a mild detergent and soft brush or cloth, inspect for wear and damage, lubricate moving parts, and store rollers properly to keep them in top condition.