Introduction

In today's fast-paced manufacturing environment, companies are constantly seeking ways to improve efficiency and reduce costs. One often overlooked area for optimization is material handling. Industrial roller solutions can provide a cost-effective means of streamlining material handling processes, resulting in improved productivity and reduced downtime.

What are Industrial Roller Solutions?

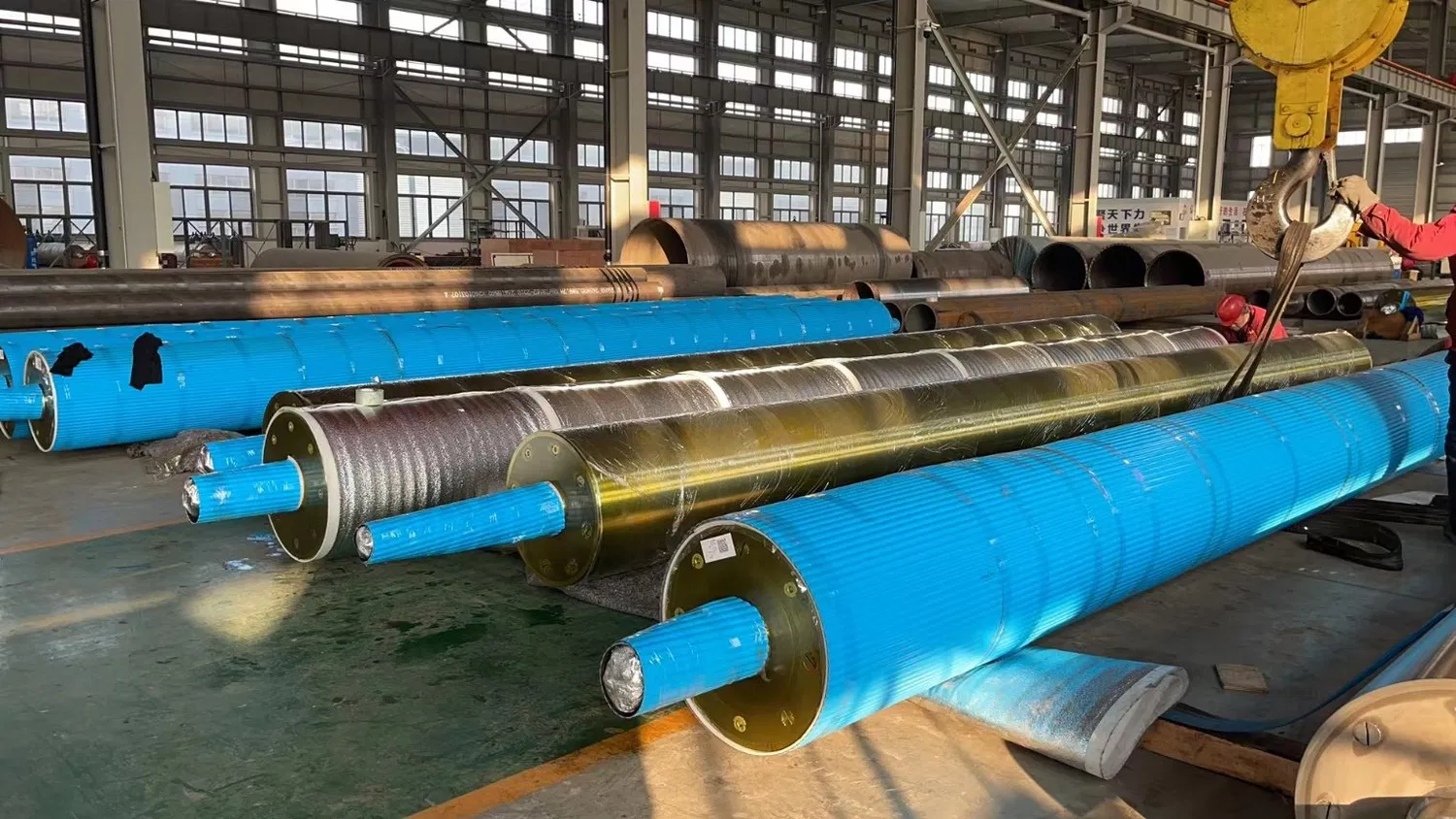

Industrial roller solutions are conveyor systems that use rollers to move materials from one point to another. These systems can be customized to meet the specific needs of a given application, and they are available in a variety of configurations, including gravity-fed, powered, and motorized roller conveyors.

Gravity-Fed Roller Conveyors

Gravity-fed roller conveyors are the simplest and most cost-effective type of industrial roller solution. These systems rely on gravity to move materials down an incline, and they are ideal for applications where products need to be moved short distances or where space is limited. Additionally, gravity-fed roller conveyors require no external power source, making them an energy-efficient option for material handling.

Powered Roller Conveyors

Powered roller conveyors are a more advanced type of industrial roller solution. These systems use motors to drive the rollers, allowing for precise control over the movement of materials. Powered roller conveyors are ideal for applications where products need to be moved over longer distances or where precise positioning is required.

The Benefits of Industrial Roller Solutions

Industrial roller solutions offer several benefits for manufacturing and material handling processes. Some of the key advantages include:

Improved Efficiency

Industrial roller solutions can significantly improve the efficiency of material handling processes. By automating the movement of materials, companies can reduce the time and labor required to move products from one point to another. This results in increased productivity and reduced costs.

Reduced Downtime

Industrial roller solutions can also help to reduce downtime in manufacturing processes. By automating material handling, companies can eliminate bottlenecks and ensure that materials are always available when needed. This results in reduced downtime and increased throughput.

Improved Safety

Industrial roller solutions can also improve safety in the workplace. By automating material handling processes, companies can reduce the risk of injury associated with manual material handling. Additionally, industrial roller solutions can be designed to meet specific safety requirements, such as the need for guardrails or emergency stop buttons.

Choosing the Right Industrial Roller Solution

When selecting an industrial roller solution, it's important to consider the specific needs of your application. Factors to consider include the type and weight of the materials being handled, the distance they need to be moved, and any specific safety requirements. Additionally, it's important to work with a reputable supplier who can provide customized solutions to meet your specific needs.

Types of Industrial Roller Solutions

There are several types of industrial roller solutions available, including:

- Roller conveyors

- Belt conveyors

- Chute conveyors

- Flexible conveyors

- Chain conveyors

Each type of conveyor has its own advantages and disadvantages, so it's important to choose the right one for your specific application.

Conclusion

Industrial roller solutions can provide a cost-effective means of optimizing material handling processes. By automating the movement of materials, companies can improve efficiency, reduce downtime, and improve safety. When selecting an industrial roller solution, it's important to consider the specific needs of your application and to work with a reputable supplier who can provide customized solutions to meet your needs.