Understanding High-Strength Roller Materials

High-strength roller materials are essential components in many industrial and manufacturing processes. These rollers are typically used in conveyor systems, printing presses, and other machinery that requires a high degree of precision and durability. Choosing the right high-strength roller material can significantly impact the performance and lifespan of your equipment.

Factors to Consider When Selecting High-Strength Roller Materials

When selecting high-strength roller materials, there are several factors to consider, including:

- Load capacity

- Speed

- Environmental conditions

- Cost

Load capacity is a critical factor to consider when selecting high-strength roller materials. The rollers must be able to withstand the weight and force of the materials they are transporting. Speed is also an essential consideration, as high-speed applications require rollers that can withstand the centrifugal forces generated.

Environmental conditions, such as temperature and humidity, can also affect the performance and lifespan of high-strength roller materials. It's essential to choose materials that can withstand the specific environmental conditions of your application. Finally, cost is always a consideration, and it's essential to choose materials that provide the best value for your budget.

Common High-Strength Roller Materials

Several high-strength roller materials are commonly used in industrial and manufacturing applications. Some of the most popular options include:

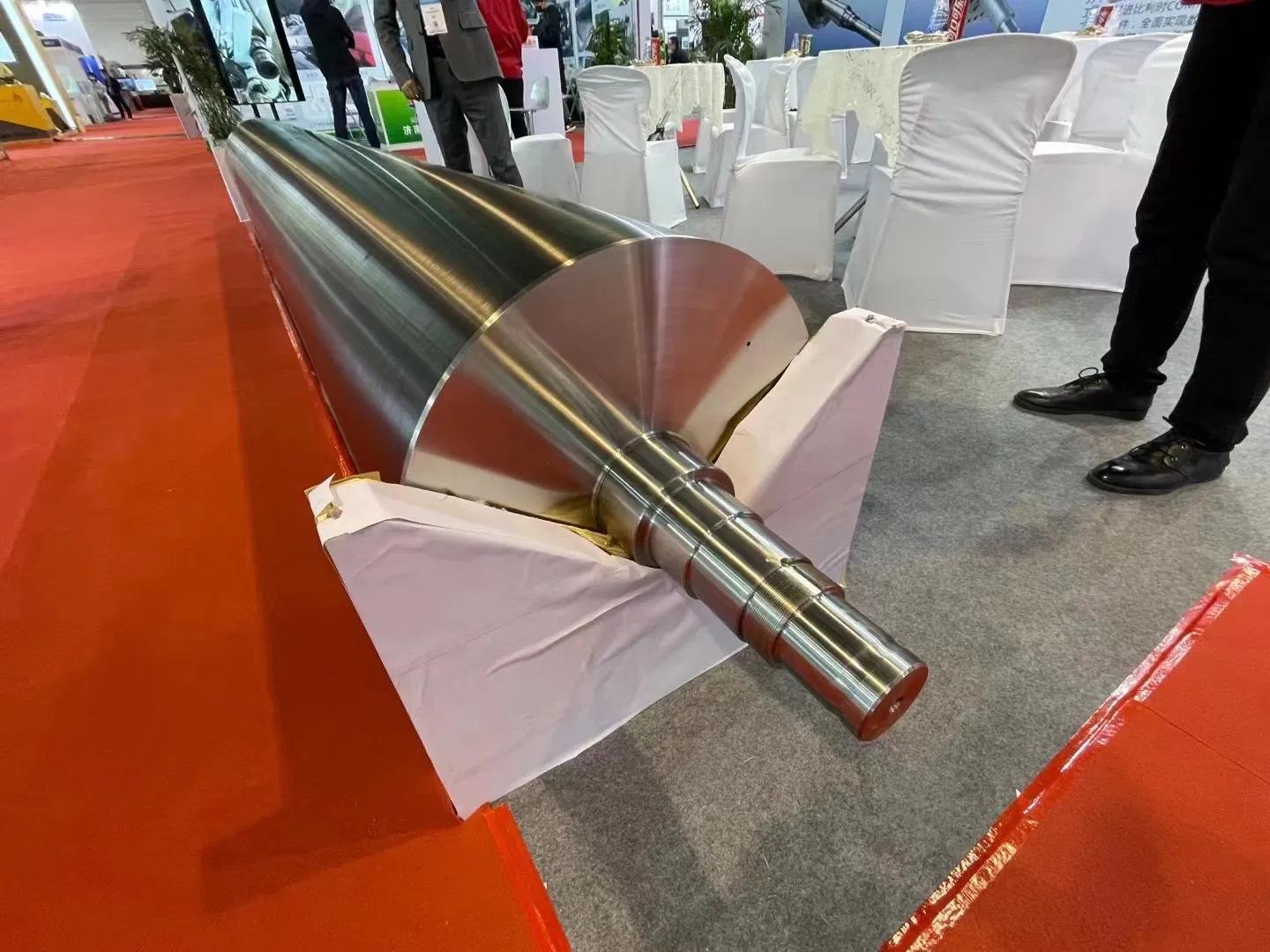

Steel Rollers

Steel rollers are a popular choice for high-strength applications due to their durability and load-bearing capacity. They are often used in heavy-duty conveyor systems and printing presses. However, steel rollers can be prone to corrosion and may require additional protection in harsh environments.

Ceramic Rollers

Ceramic rollers are an excellent choice for high-speed applications due to their low coefficient of friction. They are also highly resistant to wear and corrosion, making them ideal for use in harsh environments. However, ceramic rollers can be more expensive than other options.

Composite Rollers

Composite rollers are made from a combination of materials, such as metal and plastic. They offer many benefits, including high load capacity, low friction, and resistance to wear and corrosion. Composite rollers are also often more cost-effective than other high-strength roller materials.

Choosing the Right High-Strength Roller Material for Your Application

When selecting high-strength roller materials, it's essential to consider the specific requirements of your application. Factors such as load capacity, speed, environmental conditions, and cost should all be taken into account. Consulting with a roller manufacturer or supplier can also be helpful in determining the best material for your needs.

Consider Custom Roller Solutions

In some cases, a custom roller solution may be necessary to meet the specific requirements of your application. Custom rollers can be designed to meet exact specifications and can be made from a variety of high-strength materials. Consulting with a roller manufacturer or supplier can help determine if a custom roller solution is the right choice for your application.

Conclusion

Choosing the right high-strength roller materials is critical to the performance and longevity of your equipment. By considering factors such as load capacity, speed, environmental conditions, and cost, you can select the best material for your needs