Introduction

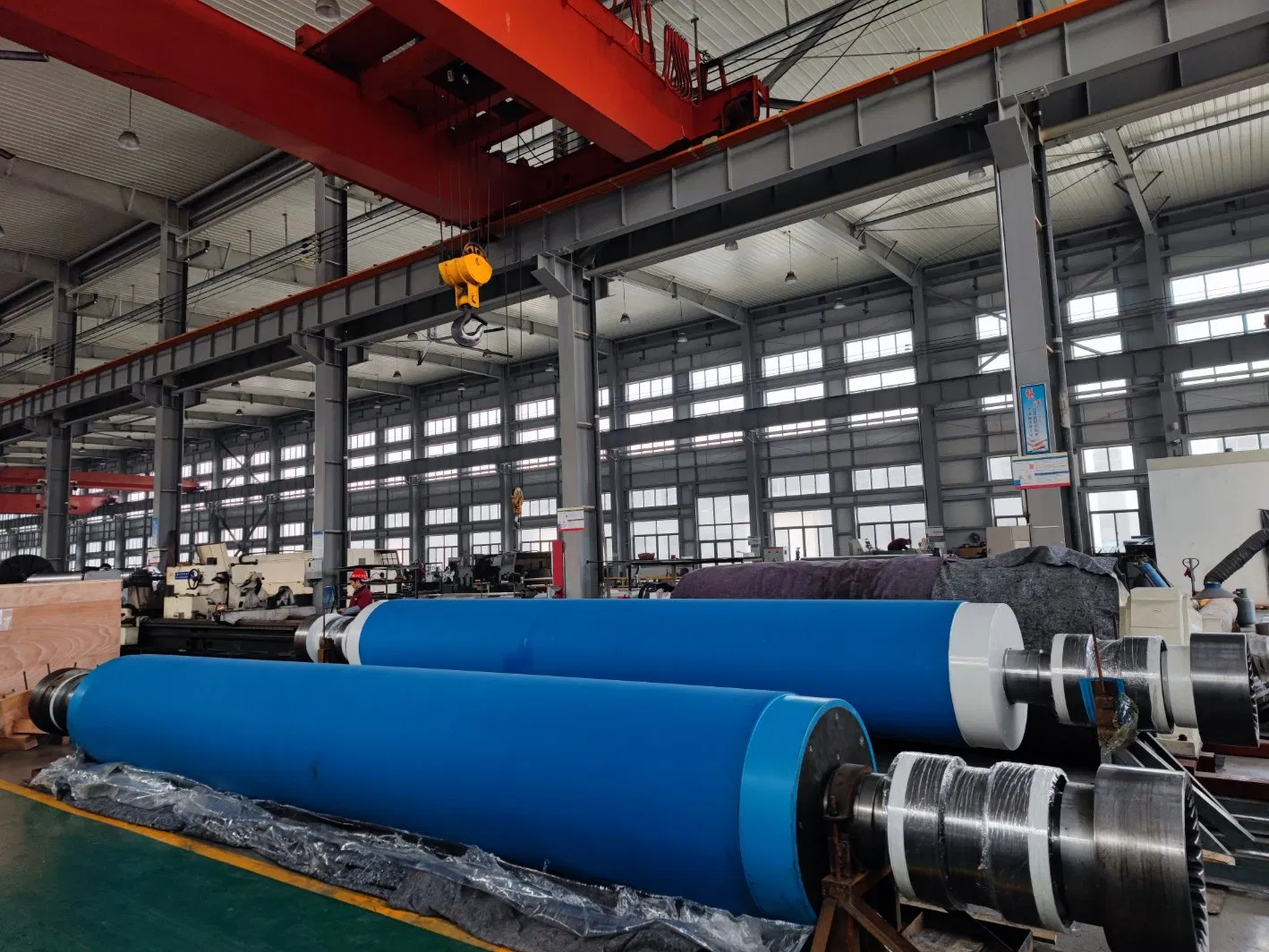

Rubber rollers are a common sight in industrial and commercial settings. They are versatile components that perform various functions, from conveying materials to applying pressure or force. These rollers come in different sizes, shapes, and materials, making them suitable for different applications. In this article, we will explore the uses, benefits, and maintenance of rubber rollers in detail.

Uses of Rubber Rollers

Rubber rollers are used in a wide range of industries, including printing, packaging, textile, paper, and metalworking. Here are some of the most common uses of rubber rollers:

Conveying Materials

Rubber rollers are often used to convey materials from one point to another. For example, in the printing industry, they are used to transfer ink from the printing plate to the substrate. In the packaging industry, they are used to move boxes, cartons, and other materials along conveyor belts.

Applying Pressure

Rubber rollers can also apply pressure or force to materials. For instance, in the textile industry, they are used to press and smooth out fabrics. In the paper industry, they are used to compress and dry paper sheets.

Protecting Surfaces

Rubber rollers are also used to protect surfaces from wear and tear. For example, in the metalworking industry, they are used to guide and support heavy metal sheets. In the construction industry, they are used to lift and move heavy objects without damaging them.

Benefits of Rubber Rollers

Rubber rollers offer several benefits over other types of rollers. Here are some of the most significant advantages:

Durability

Rubber rollers are highly durable and can withstand heavy use without breaking down. They are resistant to wear and tear, abrasion, and corrosion, making them ideal for use in harsh environments.

Flexibility

Rubber rollers are highly flexible and can conform to the shape of the material they are conveying or applying pressure to. This makes them suitable for use in applications where precision and accuracy are essential.

Noise Reduction

Rubber rollers produce very little noise compared to other types of rollers. This makes them ideal for use in quiet environments or applications where noise reduction is a priority.

Maintenance of Rubber Rollers

Proper maintenance is essential to ensure the longevity and performance of rubber rollers. Here are some maintenance tips:

Cleaning

Regular cleaning is necessary to remove dirt, debris, and other contaminants that can damage the rubber roller. Use a soft brush or cloth to clean the roller, and avoid using harsh chemicals that can damage the rubber.

Lubrication

Lubrication is necessary to reduce friction and wear on the rubber roller. Use a high-quality lubricant that is compatible with the rubber material. Apply the lubricant evenly across the roller surface.

Inspection

Regular inspection is necessary to identify any signs of wear or damage. Check for cracks