The Ultimate Guide to Rubber Roller: Types, Applications, and Maintenance

First Section: Types of Rubber Rollers

Rubber rollers are an essential component in many industrial applications. They come in various types, each with unique properties suited for specific tasks. Here are some common types:

- Natural rubber rollers: Made from natural latex, these rollers offer excellent resilience and abrasion resistance.

- Synthetic rubber rollers: Produced from synthetic polymers, these rollers have superior chemical and heat resistance.

- Hard rubber rollers: Featuring a high durometer rating, these rollers are ideal for high-pressure and heavy-load applications.

- Soft rubber rollers: With a low durometer rating, these rollers provide excellent grip and conformability.

Subsection 1: Choosing the Right Rubber Roller

Selecting the right rubber roller depends on factors such as the application, operating conditions, and required performance. Consulting with a roller manufacturer or supplier can help ensure that you choose the best rubber roller for your needs.

Second Section: Applications of Rubber Rollers

Rubber rollers are found in a wide range of industries and applications, including:

- Printing: Rubber rollers are used in printing presses to transfer ink to various substrates.

- Paper and textile manufacturing: Rubber rollers help in web handling, guiding, and tension control.

- Food processing: Rubber rollers are used in conveyors, mixers, and other equipment for processing and packaging food products.

- Metal forming: Rubber rollers are used in roll forming, bending, and straightening operations.

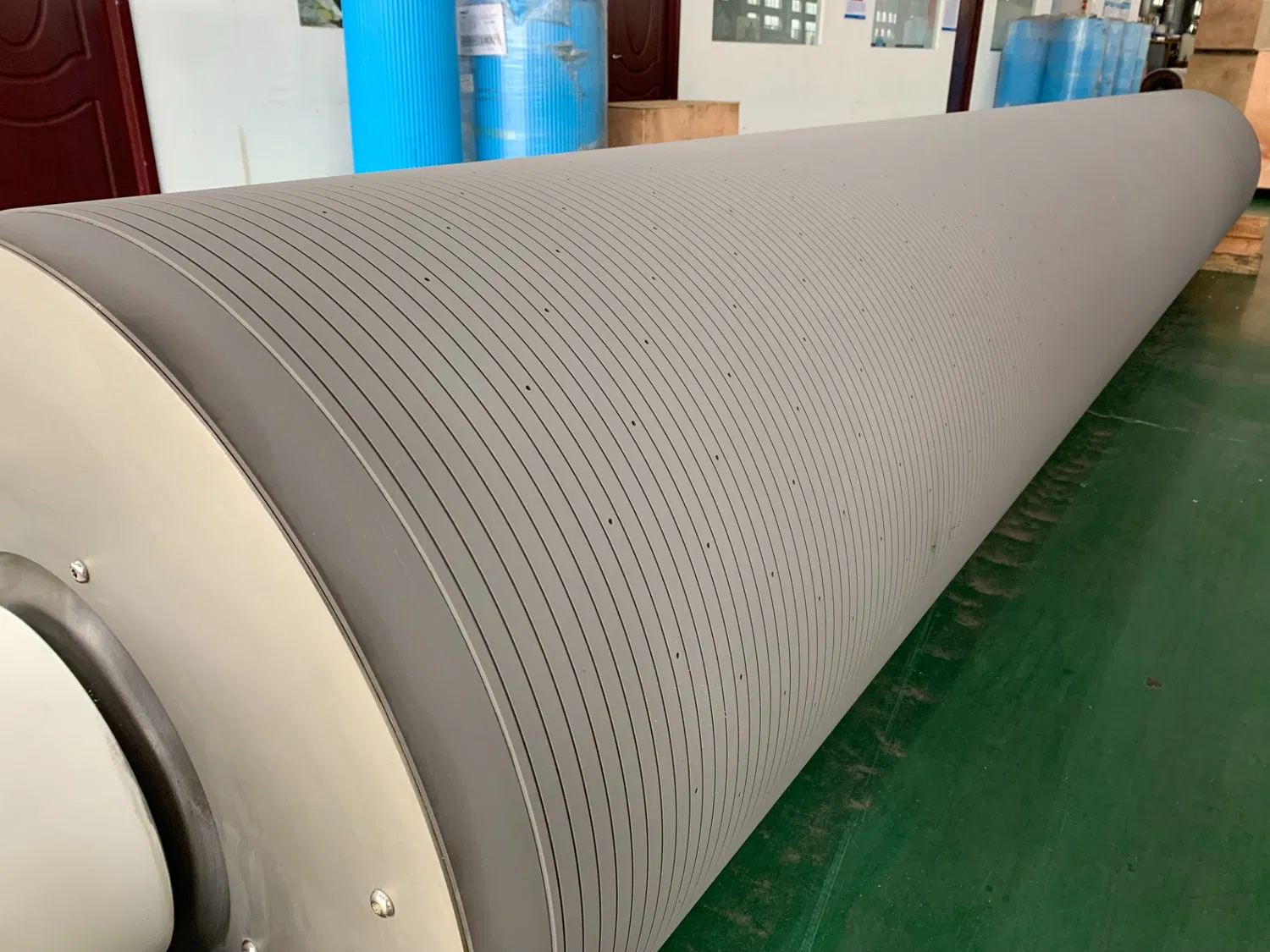

Subsection 2: Custom Rubber Rollers

For specialized applications, custom rubber rollers can be manufactured to meet specific requirements. These rollers can be designed with unique dimensions, shapes, and surface patterns to optimize performance.

Third Section: Maintaining Rubber Rollers

Proper maintenance is crucial for ensuring the longevity and performance of rubber rollers. Here are some tips:

- Regular cleaning: Clean rollers periodically to remove dirt, dust, and debris that can cause wear and tear.

- Lubrication: Apply lubricant to bearings and other moving parts to reduce friction and prevent corrosion.

- Inspection: Regularly inspect rollers for signs of wear, damage, or misalignment, and replace or repair them as needed.

Subsection 3: Storage and Handling

Proper storage and handling practices can help prevent damage to rubber rollers. Store rollers in a clean, dry environment away from direct sunlight, heat sources, and chemicals. When handling rollers, use appropriate equipment and techniques to avoid damaging the roller surface or causing deformation.

Fourth Section: Conclusion

Rubber rollers play a critical role in numerous industrial applications. By understanding the different types, applications, and maintenance requirements, you can ensure optimal performance and longevity of your rubber rollers. Consult with a reputable roller manufacturer or supplier for expert advice and custom solutions tailored to your specific needs.