In the demanding world of paper manufacturing, every component plays a vital role in the final product's quality, machine efficiency, and operational costs. Among the most critical, yet sometimes overlooked, are the rolls that guide and process the paper web. These rolls, often massive and subjected to immense pressure, temperature, and chemical exposure, rely heavily on their outer layer – the roll cover. Understanding the intricacies of paper machine roll covers isn't just about maintenance; it's about unlocking potential performance gains across the entire production line. Frankly speaking, the right cover can mean the difference between consistent, high-quality output and frequent, costly downtime. These covers protect the roll body, provide the necessary surface properties for interaction with the paper web and felts, and influence processes like dewatering, pressing, and calendering. Their performance directly impacts sheet moisture profile, uniformity, strength, and even the machine's energy consumption. Have you ever considered just how much sheet quality is determined at the nip, and how the cover material and surface are instrumental in that interaction? It's a fascinating area where material science meets mechanical engineering and process control, all converging on a thin layer around a rotating cylinder. This article will delve into why selecting, maintaining, and optimizing these crucial components is paramount for any paper mill striving for excellence.

The Critical Role and Types of Paper Machine Roll Covers

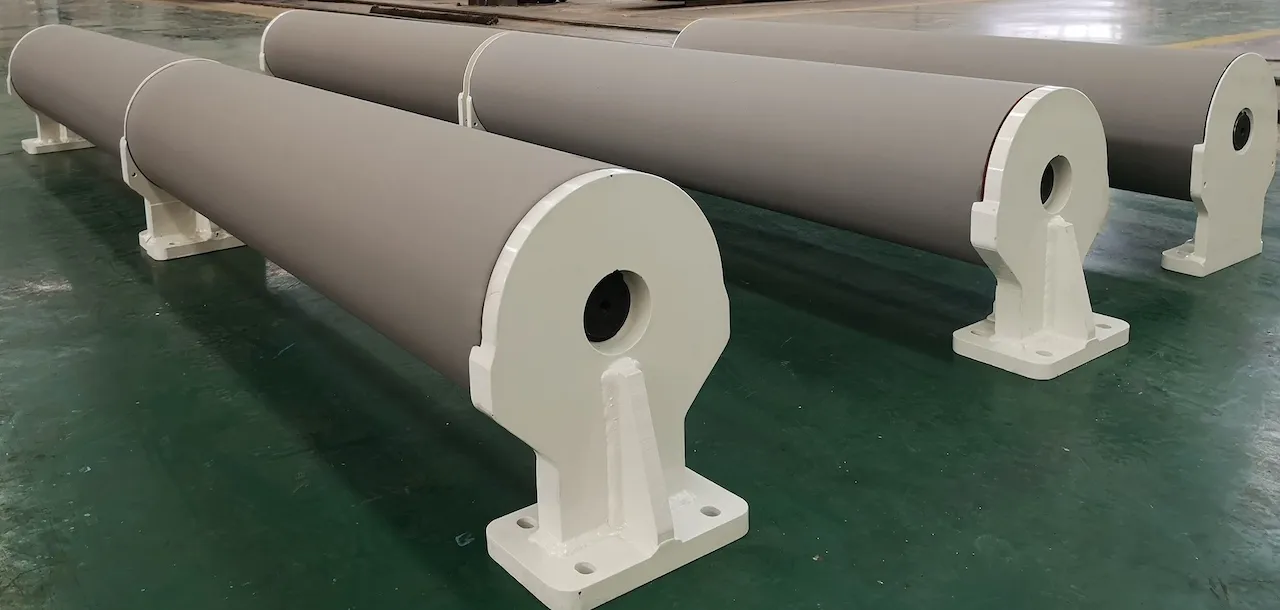

Paper machine roll covers are far more than just protective sleeves; they are active participants in the papermaking process. Depending on their position in the machine – be it in the forming section, press section, dryer section, or calender – they encounter vastly different environments and perform distinct functions. In the press section, for instance, covers must withstand extreme pressures while facilitating efficient dewatering and preventing crushing or marking of the wet sheet. Dryer section covers face high temperatures and moisture variations, requiring materials that resist heat degradation and build-up. Calender roll covers, conversely, need specific hardness and surface finishes to impart the desired smoothness and gloss to the dry sheet. Due to these varied demands, a wide array of materials are utilized for paper machine roll covers. Traditionally, rubber compounds were dominant, offering elasticity and good wear resistance. However, advancements in polymer science have introduced polyurethane covers, known for their superior abrasion resistance, load-bearing capabilities, and chemical stability, making them ideal for demanding press positions. Composite materials, often reinforced with fibers, offer exceptional stiffness, strength, and dimensional stability, suitable for rolls requiring minimal deflection under load. The selection of the appropriate cover material, durometer (hardness), thickness, and even surface geometry (like grooving or drilling patterns) is a complex decision heavily influenced by the specific machine position, operating conditions, paper grade being produced, and desired outcomes. It's worth noting that material properties like elasticity, thermal conductivity, and chemical inertness are carefully engineered into these covers to meet the rigorous requirements of the modern paper machine, contributing significantly to overall roll performance.

Matching Covers to Machine Position and Process Needs

Selecting the correct roll cover isn't a one-size-fits-all proposition; it requires a deep understanding of the specific role the roll plays within the paper machine. Consider the press section, a high-stress environment crucial for dewatering. Press roll covers need to be resilient, capable of distributing pressure evenly across the nip to avoid localized overloading that can damage the sheet or the roll body. Materials like specialized polyurethanes or hard rubber are often chosen here, sometimes with complex grooving or blind-drilling patterns to manage water flow out of the nip. Compare this to a couch roll in the forming section, where vacuum is applied to initiate dewatering. The cover needs sufficient open area (often achieved through drilling) and material properties that resist blinding (clogging) from pulp fines. Or think about a size press or coating roll, where the cover must apply a uniform layer of liquid medium to the paper surface without streaks or inconsistencies, requiring a specific surface energy and finish. Even within the dryer section, felt rolls require different cover properties than guide rolls. This intricate relationship between machine position, process requirements, and cover material properties underscores the importance of expert consultation. Many mills seek out specialists to analyze their unique operational parameters – including line speed, web width, nip loads, temperatures, furnish type, and chemical additives – to recommend the most suitable cover solution. Getting this selection right is a foundational step towards achieving consistent quality and maximizing the operational efficiency of your rolls, directly impacting the potential for optimized roll performance across the entire line.

Strategies for Extending Paper Machine Roll Cover Lifespan

Investing in high-quality paper machine roll covers is significant, and maximizing their operational life is crucial for controlling costs and minimizing downtime. The lifespan of a roll cover is influenced by numerous factors, including the initial material quality, the severity of the operating environment, and critically, the diligence of maintenance practices. Effective maintenance goes beyond simply repairing damage; it involves proactive monitoring, regular inspection, and scheduled reconditioning. Grinding is perhaps the most common maintenance activity for roll covers. Over time, covers develop uneven wear profiles, flat spots, or surface imperfections due to continuous running under load, sometimes compounded by abrasive furnish or chemical attack. Periodic grinding restores the cover's cylindrical profile and surface finish, ensuring uniform nip pressure and preventing defects like barring or calendering issues. The frequency and depth of grinding depend on the cover material, machine position, and wear rate, but neglecting this can lead to premature failure or performance degradation. Cleaning is another vital aspect, as build-up of pitch, stickies, or calcium carbonate can alter the cover's surface properties and impact sheet release or dewatering. Utilizing appropriate cleaning showers and chemicals during operation, or thorough cleaning during shutdowns, helps maintain optimal surface conditions. Furthermore, regular inspections for cracks, blisters, or signs of chemical attack allow for early detection of problems before they escalate into catastrophic failures. Implementing a robust roll maintenance program, including detailed historical tracking of each cover's service life, grinding history, and performance observations, is key to understanding wear patterns and optimizing the schedule for reconditioning or replacement, thereby significantly contributing to extending roll cover lifespan.

Effective Maintenance and Reconditioning Practices

Diving deeper into maintenance, effective reconditioning practices are fundamental to maximizing the value derived from paper machine roll covers. When a cover shows signs of wear or damage that regular cleaning or in-situ grinding cannot rectify, it's often sent back to a specialized service provider for reconditioning. This process typically involves thorough inspection, stripping down damaged layers if necessary, and professional grinding or machining to restore the precise geometry and surface finish. For certain materials, like polyurethane, it might even involve patching minor damage or applying specialized coatings. The goal is always to return the cover to a condition where it can perform optimally as if it were new, or at least within acceptable tolerances for its specific application. Proper storage of spare rolls is also part of effective maintenance. Rolls should be stored horizontally on suitable racks, away from extreme temperatures, direct sunlight, and chemical exposure that could degrade the cover material. Rotating stored spares periodically can help prevent flat spots. Moreover, handling practices during installation and removal are crucial; dropping or bumping a roll can cause irreparable damage to the cover or the roll body itself. Investing in proper lifting equipment and training personnel on safe handling procedures is essential. Many paper mills work closely with their roll cover suppliers or specialized service centers to develop tailored maintenance programs. These partnerships often include predictive maintenance strategies based on monitoring vibrations, temperature, and nip profiles, allowing for scheduled maintenance interventions before a failure occurs. This proactive approach not only extends the life of the cover but also minimizes unexpected downtime, which, frankly speaking, is one of the most significant costs in paper production.

Optimized Roll Performance Through Customization

Achieving truly optimized roll performance goes beyond selecting a standard cover material and following basic maintenance. It increasingly involves customization tailored to the specific needs and challenges of an individual paper machine or even a particular roll position within that machine. While standard cover compounds and designs serve a broad range of applications, slight modifications in material composition, hardness profiles, or surface topography can yield significant improvements in efficiency, quality, and lifespan. For instance, a press roll cover in a machine running high-fill paper might benefit from a slightly different polymer blend that offers enhanced release properties and resistance to stickies build-up. A calender roll cover needing to impart a specific low-gloss finish might require a unique surface texture or coating not found on standard covers. Customization can also involve innovative grooving or drilling patterns engineered to optimize dewatering rates at specific speeds or handle unusual flow patterns in the nip. Some advanced covers incorporate multi-layer designs, combining different materials to achieve properties that a single material cannot provide, such as a hard, wear-resistant outer layer bonded to a softer, more compliant base layer for better load distribution. Collaborating with a roll cover manufacturer that offers strong R&D capabilities and customization services allows mills to fine-tune their roll performance. This might involve laboratory testing of material samples under simulated conditions or pilot trials on a smaller scale. The insights gained from such collaboration can lead to roll cover solutions that precisely match the paper grade, machine speed, and desired quality attributes, providing a competitive edge and demonstrating the profound impact that specialized paper machine roll covers can have on the overall operational output and quality of the final product.

How Cover Design Impacts Machine Efficiency

The design of a paper machine roll cover has a direct and measurable impact on various aspects of machine efficiency. Take the press section, where efficient dewatering is key to reducing the energy required for subsequent drying. The cover's material properties, hardness, and surface design (like grooving or drilling) directly affect how effectively water is removed from the sheet in the press nip. An optimized cover design can lead to higher sheet dryness entering the dryer section, resulting in lower steam consumption and increased machine speed – a clear win for energy efficiency and productivity. Similarly, in the calender section, the cover's material and surface finish dictate the quality of the sheet surface – its smoothness, gloss, and caliper. A cover that provides a consistent and uniform nip allows for predictable calendering results, reducing the need for reruns or adjustments and minimizing waste. In positions where web handling is critical, like guide or spreader rolls, the cover material and surface texture influence traction and web control, helping to prevent wrinkles, breaks, and leading to smoother machine operation. Even the dynamic properties of the cover, such as its vibration dampening characteristics, can impact machine runnability and the lifespan of bearings and other components. Interestingly enough, advancements in cover technology now include smart covers with embedded sensors that can monitor temperature, pressure, or vibration in real-time, providing data for predictive maintenance and process optimization. All these examples highlight that the seemingly simple roll cover is, in fact, a sophisticated engineering component whose design choices profoundly influence the overall efficiency and performance of the paper machine line. Achieving peak optimized roll performance is intrinsically linked to the intelligent selection and design of these critical covers.

Addressing Common Issues and Preventing Failures

Despite being engineered for toughness, paper machine roll covers operate in harsh conditions and are susceptible to various issues and potential failures. Common problems include wear (both abrasive and chemical), cracking, blistering, delamination from the roll body, barring (uneven wear patterns causing ripples), and build-up of contaminants. Understanding the root causes of these issues is vital for prevention. Abrasive wear is often linked to the presence of fillers or pigments in the furnish, or insufficient lubrication in the nip. Chemical attack can occur from process chemicals or cleaning agents that are incompatible with the cover material. Cracking and blistering can result from thermal cycling, excessive localized pressure, or inadequate bonding to the roll core. Delamination is typically a bonding failure issue, often triggered by excessive heat, chemical attack on the bond line, or improper application during manufacture. Barring is a complex phenomenon often related to roll dynamics, resonance, or uneven load distribution, but the cover's properties and uniform hardness are critical factors. Preventing these issues requires a multi-pronged approach. Firstly, ensuring the correct cover material is selected for the specific operating environment is paramount. Secondly, implementing rigorous maintenance practices, including regular inspection, cleaning, and scheduled grinding, helps to mitigate wear and detect early signs of failure. Thirdly, controlling process parameters like temperature, pH, and chemical concentrations can minimize chemical attack and thermal stress. Finally, working with a reliable roll cover supplier who adheres to strict manufacturing quality control standards is essential to prevent issues stemming from poor bonding or material inconsistencies. Proactive measures, from material selection to diligent maintenance, are the most effective ways to avoid costly failures and maintain the operational integrity of your paper machine roll covers.

Partnering for Roll Cover Success

Given the complexity of roll cover technology and the significant impact these components have on overall paper machine performance, partnering with a knowledgeable and experienced supplier is a strategic decision. A good partner offers more than just a product; they provide expertise, technical support, and insights gained from working with numerous mills and diverse applications. They can assist in selecting the optimal cover material and design based on your specific machine configuration, operating conditions, and production goals. They can help troubleshoot ongoing issues, analyze failed covers to determine root causes, and recommend adjustments to process or maintenance practices. Many leading suppliers offer comprehensive services, including roll cover manufacturing, grinding and reconditioning services, and even performance monitoring solutions. Such a partnership can lead to improved roll cover lifespan, reduced maintenance costs, enhanced sheet quality, and overall gains in machine efficiency. It allows mill personnel to leverage external expertise, keeping pace with the latest advancements in materials and cover technologies without needing to develop that specialized knowledge internally. When evaluating potential partners for your paper machine roll covers, consider their experience in your specific paper grades, their technical support capabilities, their manufacturing quality standards, and their commitment to R&D and innovation. A strong partnership is an investment in the reliability and performance of your paper machine, leading to smoother operations and a better bottom line.

Conclusion: Elevating Performance with Expert Roll Covers

Ultimately, optimizing the performance of your paper machine hinges significantly on the performance of its rolls, and that performance is intrinsically linked to the quality and suitability of the roll covers. From the forming section to the calender, each roll position presents unique challenges that demand specific cover properties. Selecting the right material, ensuring proper maintenance, and exploring opportunities for customization are all critical steps towards achieving optimized roll performance, enhancing sheet quality, reducing energy consumption, and minimizing costly downtime. While the initial investment in high-quality covers and professional maintenance may seem substantial, the long-term benefits in terms of increased productivity, lower operating costs, and consistent product quality far outweigh the expenditure. Continuous monitoring of roll cover performance, combined with a proactive maintenance strategy and a strong partnership with a knowledgeable supplier, forms the bedrock of successful roll management in a modern paper mill. If you are experiencing issues with premature wear, inconsistent sheet quality, or excessive downtime related to your rolls, perhaps it's time to take a closer look at your roll cover strategy. Don't underestimate the power of these critical components; they hold significant potential for unlocking efficiency and profitability in your papermaking operation. Taking the next step involves reviewing your current roll performance data, assessing your specific operational challenges, and consulting with experts who can provide tailored solutions for your paper machine roll covers.

For more detailed information, please visit our official website: paper machine roll covers