In the complex world of papermaking, every component plays a vital role in the final product's quality and the efficiency of the production line. Among these critical parts, blind hole press rolls stand out as indispensable elements in the press section, designed specifically to remove water from the paper web. Their effectiveness directly impacts the dryness of the sheet before it enters the dryer section, which in turn significantly affects energy consumption and machine speed. Consequently, selecting reliable and expert blind hole press roll manufacturers isn't just a technical decision; it's a strategic one that can profoundly influence operational costs and output. This article delves into what makes these rolls so crucial and what you should look for in a manufacturer to ensure you get the best possible performance and longevity from your equipment.

The Essential Role of Blind Hole Press Rolls in Papermaking

The press section of a paper machine is where the majority of water is removed from the paper web through mechanical pressure. While heat drying consumes vast amounts of energy, pressing is a far more energy-efficient method. Blind hole press rolls are specifically engineered to maximize this mechanical dewatering process. Unlike plain rolls, these rolls are covered with thousands of small, precisely drilled holes or blind cavities on their surface. As the paper web passes through the nip between two rolls (at least one of which is typically a blind hole roll), water is squeezed out of the sheet. Without these holes, the water would have nowhere to go but back into the sheet as soon as the pressure is released, or it would create damaging hydraulic pressure within the nip. The blind holes provide tiny reservoirs for this expelled water, allowing it to be carried away and preventing rewetting of the paper web. Frankly speaking, this ingenious design is fundamental to achieving high dryness levels and efficient operation.

Understanding How Blind Holes Optimize Dewatering Performance

The mechanics behind the effectiveness of blind holes are quite fascinating. When the paper web, felt (which carries the web), and the blind hole roll pass through the pressure nip, tremendous force is applied. Water is expelled from the felt and web into the tiny blind holes on the roll surface. These holes are "blind" because they do not go all the way through the roll shell; they are essentially dimples. This design prevents water from being drawn through the roll shell and keeps it temporarily captured in the holes. As the roll surface emerges from the pressure nip, centrifugal force and vacuum (often applied internally on subsequent vacuum rolls) help to remove the water from the holes. This process dramatically reduces the hydraulic pressure within the nip, which can otherwise limit dewatering and even cause damage to the sheet structure. A well-designed blind hole pattern, considering hole diameter, depth, spacing, and total open area, is crucial for optimal water removal without marking the sheet. Many experts agree that getting the hole geometry just right is a true mark of a skilled manufacturer.

Key Criteria for Selecting Blind Hole Press Roll Manufacturers

Choosing the right partner among the many blind hole press roll manufacturers available globally requires careful consideration. It's not just about finding someone who can produce a roll with holes; it's about finding a manufacturer with the expertise, technology, and commitment to quality necessary to produce rolls that will perform reliably under the demanding conditions of a paper machine. Experience is paramount; a manufacturer who understands the nuances of different paper grades, machine speeds, and operational pressures will be better equipped to recommend and produce the most suitable roll design for your specific needs. Their technical capabilities, including advanced machining centers, precision drilling equipment, and sophisticated quality control systems, are non-negotiable. Furthermore, the ability to offer custom solutions and provide ongoing support, from installation to maintenance advice, speaks volumes about their dedication to customer success. Have you ever wondered about the significant difference a truly expert manufacturer can make?

The Importance of Material Science and Manufacturing Precision

The performance and lifespan of a blind hole press roll are heavily dependent on the materials used and the precision of the manufacturing process. The roll shell material itself, whether it's cast iron, steel, or a composite, must be chosen based on strength, corrosion resistance, and suitability for the intended covering (rubber, polyurethane, or ceramic). The application of the roll cover is another critical step, requiring specialized knowledge and equipment to ensure proper adhesion, uniform thickness, and the desired surface properties. Interestingly enough, the drilling of the blind holes is perhaps the most complex and critical part of the manufacturing process. It requires high-precision CNC drilling machines that can place thousands of holes with extreme accuracy in terms of pattern, depth, and diameter. In my experience, even minor deviations in hole drilling can lead to uneven dewatering, vibration, or premature cover wear. A top-tier manufacturer invests heavily in both material science expertise and state-of-the-art precision machining technology to ensure every roll meets stringent specifications.

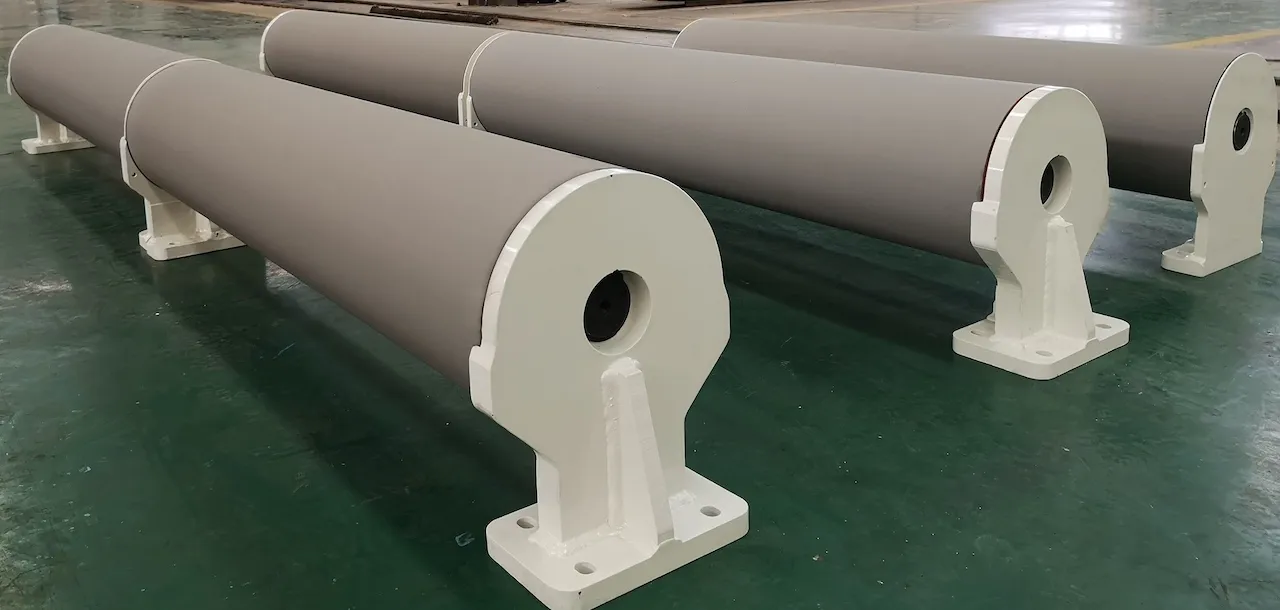

Varieties and Applications of Blind Hole Press Rolls

Blind hole press rolls come in various configurations to suit different positions and functions within the press section and different types of paper machines. The most common type features a metallic core with a rubber or synthetic cover into which the blind holes are drilled. However, variations exist, including rolls with specialized synthetic covers offering different hardness and surface properties, or even metal-covered rolls for specific applications. The pattern and dimensions of the blind holes also vary significantly. Factors like hole diameter, depth, the angle of drilling, and the overall percentage of the roll surface covered by holes (known as the open area) are customized based on the type of paper being produced, the desired dryness level, and the felt design used. For instance, a roll designed for a high-speed newsprint machine might have a different hole pattern compared to one for a slower specialty paper machine. Understanding these variations and their impact on performance is essential, and a knowledgeable manufacturer can guide you through the options.

The Meticulous Process of Manufacturing High-Quality Rolls

The creation of a high-quality blind hole press roll is a multi-stage process demanding significant expertise and technical infrastructure. It typically begins with sourcing or casting/forging the core roll shell, followed by initial machining to achieve the basic shape and dimensions. If a cover is required, it is then applied using specialized bonding techniques. The roll then undergoes precision machining to attain the exact diameter, crown profile (a slight curve to counteract deflection under pressure), and surface finish. The critical step of drilling the blind holes follows, using sophisticated CNC machines guided by precise digital patterns. This phase is meticulous and time-consuming, as any error can compromise the roll's performance. After drilling, the roll is cleaned, and potentially undergoes further surface treatments. Balancing is another crucial step to prevent vibration at high operating speeds. To be honest, seeing the level of detail and precision involved in manufacturing these rolls gives you a real appreciation for the engineering behind them.

Ensuring Performance Through Rigorous Quality Control

For leading blind hole press roll manufacturers, quality control is not an afterthought; it is integrated throughout the manufacturing process. Before drilling, the roll shell and cover are typically inspected using non-destructive testing methods (like ultrasonic testing or dye penetrant inspection) to ensure there are no internal flaws. During and after drilling, each roll undergoes thorough dimensional inspection, checking the roll diameter, crown profile, total indicated runout (TIR), and critically, the accuracy and consistency of the blind holes themselves. Surface roughness measurements are also performed. Balancing, mentioned earlier, is done to very tight tolerances to ensure smooth operation at speed. Frankly speaking, a manufacturer with robust quality control procedures, adhering to international standards, provides assurance that the roll will perform as expected and have a long, reliable service life. Don't underestimate the value of a manufacturer who stands by their quality with verifiable testing protocols.

The Bottom Line: Why Manufacturer Choice is Crucial for Your Operation

Ultimately, the performance of your press section, and thus your entire paper machine, is heavily reliant on the quality and reliability of its components, especially the blind hole press rolls. Choosing an inexperienced or under-equipped manufacturer can lead to a host of problems, including premature wear of the roll cover, uneven dewatering across the sheet width, vibration issues leading to sheet breaks and machine damage, and a shorter overall roll lifespan. These issues translate directly into increased maintenance costs, reduced machine speed, lower paper quality, and significant downtime. By partnering with reputable, experienced blind hole press roll manufacturers who prioritize precision engineering, quality materials, and rigorous testing, you are making an investment in the efficiency, stability, and profitability of your papermaking operation. It's an area where cutting corners simply doesn't pay off in the long run.

In conclusion, blind hole press rolls are indispensable workhorses in the papermaking process, crucial for efficient water removal and energy saving. The performance of these rolls is inextricably linked to the expertise and capabilities of the manufacturer who produces them. From the initial design and material selection to the precision drilling and rigorous quality control, every step in the manufacturing process matters. When seeking blind hole press roll manufacturers, prioritize experience, technical capability, quality assurance, and a willingness to provide tailored solutions. Investing time and effort in finding the right supplier will pay dividends in terms of roll longevity, machine performance, and overall operational efficiency.

Considering the critical nature of these components, taking the next step is important. Research manufacturers thoroughly, ask for case studies or references, and discuss your specific operational requirements in detail. A professional manufacturer will welcome these discussions and demonstrate their understanding of your challenges. Understanding their manufacturing process and quality control standards will give you confidence in your choice. For more detailed information, please visit our official website: blind hole press roll manufacturers