In the intricate world of paper manufacturing, efficiency hinges significantly on the performance of critical components within the paper machine. Among these, the press section plays a pivotal role in removing water from the paper web, a process that directly impacts energy consumption, paper quality, and machine speed. At the heart of many modern press sections lies the blind hole press roll. These specialized rolls feature a pattern of holes drilled into their surface, designed to receive water pressed out of the paper web, preventing rewetting and facilitating drainage. While standard blind hole rolls serve a foundational purpose, the true potential for optimization often lies in a more tailored approach – specifically, the creation and implementation of a blind hole press roll customized to the unique demands of a particular machine, paper grade, or operating condition. This isn't just about replacing a worn part; it's about engineering a solution that integrates seamlessly with the existing setup, addresses specific challenges, and pushes the boundaries of dewatering efficiency. To be honest, overlooking the potential for customization means leaving performance on the table.

The Essence of Blind Hole Press Rolls in Paper Manufacturing

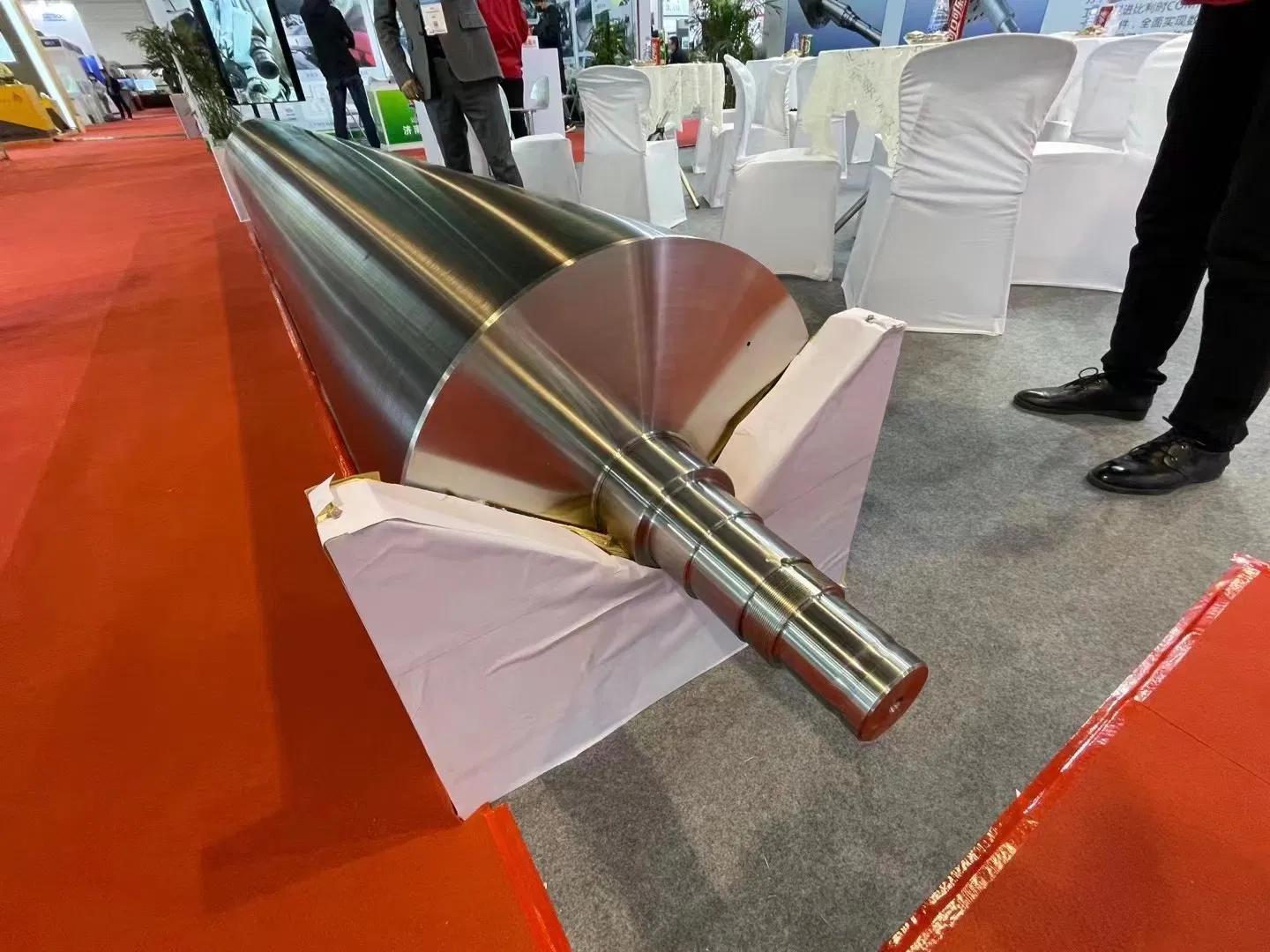

Understanding the fundamental purpose of blind hole press rolls is key to appreciating the value of customization. These rolls are strategically placed in the press section to apply significant pressure to the paper web as it passes between two rolls, typically a blind hole roll and a granite or covered roll. The primary function is mechanical dewatering – squeezing water out of the fibrous web. The innovation of blind holes lies in providing voids on the roll surface into which this expelled water can move. Without these holes, the water would have nowhere to go except back into the paper web, a phenomenon known as rewetting. Rewetting severely hampers dewatering efficiency, requires more energy in the subsequent drying section, and can negatively impact paper strength and uniformity. Blind holes act as miniature reservoirs, drawing water away from the nip and allowing it to drain away later through suction boxes or simply by gravity as the roll surface leaves the nip. The geometry and pattern of these holes are not arbitrary; they are carefully calculated to maximize water removal under pressure while maintaining the structural integrity of the roll and minimizing negative effects like vibration or marking the paper. Frankly speaking, a poorly designed blind hole pattern can be worse than a plain roll in some cases, highlighting why precision and application-specific design are paramount, leading us directly to the need for tailored solutions rather than off-the-shelf options that might not be perfectly suited to the task at hand in a specific machine or paper grade.

Understanding the Role of Hole Patterns and Geometry

The specific design of the blind holes within a blind hole press roll customized solution is arguably where much of the performance optimization occurs. It's not merely about drilling holes; it's about the science behind their arrangement, depth, diameter, and even the profile of their opening. The pattern of holes, whether it's a straightforward diagonal, a staggered design, or a more complex arrangement, influences how effectively water is captured and released, how the pressure is distributed across the nip, and how smoothly the roll operates. Hole depth affects the volume of water that can be accommodated and the structural strength of the roll surface. Hole diameter influences drainage speed and the likelihood of fiber accumulation or clogging. The angle of the drill bit can even be optimized. Interestingly enough, subtle changes in these parameters, when expertly engineered, can yield significant improvements in dewatering efficiency, leading to higher solids content entering the dryer section and thus reducing energy costs and potentially increasing machine speed. Furthermore, the hole pattern must be designed to avoid creating patterns or markings on the sensitive paper web, especially critical for fine paper grades. This level of detailed consideration into the nuances of hole design is only truly achievable through a customized approach, where the specific needs and constraints of the customer's operation are taken into account from the initial design phase, ensuring the blind hole press roll is perfectly matched.

Why Customization is Crucial for Optimal Press Roll Performance

The reason a one-size-fits-all approach often falls short when it comes to blind hole press rolls is the sheer diversity of paper machines, paper grades, and operating environments found across the industry. No two paper machines are exactly alike; they vary in age, design, speed, loading capacity, and configuration of the press section. Similarly, different paper grades – from fine printing papers to packaging board or tissue – have vastly different fiber compositions, moisture profiles, and strength characteristics that influence how they respond to pressing. The furnish (the mixture of water and fibers) can change, the press loading can vary, and the desired machine speed might be higher or lower. A standard blind hole roll designed for a general application might perform adequately, but it won't unlock the full potential for efficiency and quality in every unique scenario. This is precisely where a blind hole press roll customized design proves invaluable. By analyzing the customer's specific operational parameters – including machine speed, nip pressure, paper grade, desired moisture content, and any historical issues like vibration or roll cover wear – engineers can tailor the blind hole pattern, roll material, cover material, and even internal features to create a roll that is optimized for that exact application. This level of specific design significantly outperforms generic solutions, leading to better dewatering, reduced energy consumption, extended roll life, and improved paper quality.

Tailoring Materials and Coatings for Specific Applications

Beyond the crucial aspect of blind hole design, customization extends significantly to the materials used for the roll shell and, critically, the roll cover. A blind hole press roll customized solution considers not just the hole pattern but also the environmental conditions and mechanical stresses the roll will endure. The base roll shell material must be strong enough to withstand immense pressures and maintain dimensional stability, often high-grade steel or cast iron, but specialized alloys might be considered for challenging environments. However, it is the roll cover that interacts directly with the paper web and the opposing roll. Covers are typically made from rubber or polyurethane composites, and their properties – hardness, elasticity, abrasion resistance, chemical resistance, and temperature tolerance – are paramount. A cover that is too hard might lead to uneven pressure distribution or excessive paper marking; one that is too soft might wear out quickly or fail to provide sufficient pressure. For a customized blind hole press roll, the cover material and its thickness are carefully selected based on the specific press configuration, operating temperature, the type of paper being run (e.g., newsprint, fine paper, board), and any chemicals used in the process. Furthermore, specialized coatings or surface treatments can be applied to enhance durability, reduce friction, or improve release properties, preventing fiber sticking or clogging of the blind holes. This multi-faceted approach to material selection ensures the customized roll not only performs optimally but also offers maximum longevity and reliability in its specific operating environment.

The Process of Developing a Customized Blind Hole Press Roll

Creating a blind hole press roll customized for a specific paper machine is a collaborative process that involves detailed analysis, expert design, and precision manufacturing. It typically begins with a thorough consultation to understand the customer's existing setup, production goals, any performance bottlenecks, and the specific challenges they face with their current rolls. This involves gathering data on machine speed, load, paper grades, fiber type, consistency, temperature, and historical data on roll performance or failure. Engineers analyze this information to determine the optimal specifications for the new roll. This isn't a quick calculation; it involves complex simulations and calculations to predict how different blind hole patterns, depths, diameters, and cover properties will interact with the paper web and the machine dynamics under operating conditions. Once the design is finalized, it moves into the manufacturing phase. This requires specialized machinery for precision drilling of the blind holes – often using advanced CNC equipment to ensure accuracy and consistency across the entire roll surface. The application and finishing of the chosen cover material also require specific expertise and equipment to ensure uniform thickness, desired hardness, and a perfect surface finish. Throughout this process, rigorous quality control checks are performed to ensure the roll meets all specifications and will integrate seamlessly into the customer's paper machine. Have you ever wondered about the sheer engineering effort that goes into a single critical component like this?

Precision Engineering and Quality Control in Custom Roll Manufacturing

The success of a blind hole press roll customized solution hinges entirely on the precision and quality control applied throughout its development and manufacturing. Unlike mass-produced components, each customized roll is essentially a unique piece of engineering tailored to a specific application. This demands exceptionally tight tolerances during the manufacturing process. The location, depth, and diameter of every single blind hole must be consistently accurate to ensure uniform dewatering and prevent vibration. The application of the roll cover is equally critical; unevenness in thickness or hardness can lead to uneven pressure profiles across the nip, resulting in inconsistent moisture content in the paper web, which affects quality and increases drying costs. Precision balancing of the finished roll is also paramount, especially for high-speed paper machines, as even slight imbalances can cause severe vibration, leading to premature wear on bearings, frames, and covers, and potentially impacting paper quality. Therefore, extensive quality checks are integrated at every stage, from verifying raw materials to inspecting the drilled pattern, confirming cover properties, and finally, high-speed dynamic balancing of the finished roll. This meticulous attention to detail ensures that the customized blind hole press roll not only fits the machine perfectly but also performs exactly as designed, providing reliable and optimized dewatering performance over its operational life. It's this commitment to precision that truly differentiates a high-quality customized roll.

Addressing Specific Challenges Through Customized Blind Hole Design

One of the most compelling reasons to opt for a blind hole press roll customized is its ability to solve specific, persistent problems within a paper machine's press section that generic rolls cannot adequately address. For instance, some machines might suffer from chronic issues like uneven moisture profiles across the paper web, leading to variability in paper quality and challenges in subsequent processes. This can often be traced back to the dewatering effectiveness (or lack thereof) of the press roll, potentially due to a blind hole pattern that isn't optimized for the specific dwell time in the nip or the paper grade's permeability. Customizing the hole pattern, depth, and even the void volume can significantly improve uniformity. Another common issue is roll vibration, which can cause machine instability, wear, and affect paper surface quality. Vibration can stem from various factors, including an inappropriate blind hole pattern interacting negatively with machine speed or frame resonance. A customized design can incorporate pattern adjustments or specialized features to mitigate these vibrations. Clogging of blind holes with fibers or contaminants is another headache; while maintenance is essential, a customized hole diameter and shape, along with an appropriate cover material, can be selected to minimize the tendency for material to stick and accumulate, reducing the frequency of cleaning shutdowns. Essentially, customization allows for a targeted engineering response to specific operational inefficiencies or mechanical issues, rather than applying a generic solution that may or may not improve the situation.

Considering Machine Dynamics and Paper Properties in Custom Designs

A truly effective blind hole press roll customized solution goes beyond just the roll itself; it involves a deep understanding of how the roll interacts with the entire paper machine system and the specific properties of the paper being produced. Machine dynamics – including speed, temperature, loading forces, and vibration characteristics – all influence the performance of the press roll. The customized design must account for the exact operating window of the machine. Similarly, the physical properties of the paper web passing through the nip are critical. Factors like basis weight, fiber type (hardwood, softwood, recycled), freeness (how easily water drains from the pulp), additives, and chemical composition all affect how water is released and how the paper behaves under pressure. For example, a highly permeable pulp might require a different blind hole volume and pattern than a less permeable one to maximize water removal within the short dwell time of the nip. The cover material's interaction with the paper surface (sticking, release, marking potential) is also paramount and must be selected based on the specific paper grade's sensitivity. Experts involved in designing a customized roll must consider these complex interdependencies. They look at the system holistically to ensure the customized roll is not just theoretically optimal but practically effective within the real-world constraints and variables of the customer's unique paper manufacturing process. Why is this integrated approach so effective? Because it addresses the problem within its complete operational context.

Long-Term Benefits and ROI of Investing in Customized Press Rolls

While the initial investment in a blind hole press roll customized solution might be higher than purchasing a standard roll, the long-term benefits and return on investment (ROI) can be substantial and far outweigh the upfront cost. The most direct benefit is often improved dewatering efficiency. Even a seemingly small increase in solids content after the press section (e.g., 1-2%) can lead to significant savings in the dryer section, which is the most energy-intensive part of the paper machine. Less water to evaporate means less steam consumption, directly reducing energy costs. This can translate into substantial monetary savings over the lifespan of the roll. Furthermore, improved dewatering can potentially allow for increased machine speed while maintaining or improving paper quality, leading to higher production throughput. Customized rolls, designed with the specific operating conditions and potential wear factors in mind, can also offer extended service life compared to generic alternatives. By selecting appropriate materials and cover properties tailored to the application, resistance to wear, chemical degradation, or damage is enhanced, reducing the frequency of roll changes and associated downtime. Reduced vibration from a properly balanced and designed customized roll also contributes to less wear on other machine components and lower maintenance costs. In my experience, these cumulative benefits – energy savings, increased production, reduced downtime, and lower maintenance – quickly add up, making the investment in customization a financially sound decision for many paper mills.

Case Studies or Examples (General) of Successful Custom Implementations

Numerous examples across the paper industry illustrate the tangible benefits of opting for a blind hole press roll customized solution. Consider a mill producing fine printing paper that was struggling with persistent barring and uneven moisture profiles, impacting printability. A detailed analysis revealed that the existing blind hole pattern was interacting unfavorably with machine speed, causing slight pressure variations and inconsistent dewatering. By engineering a customized blind hole pattern and selecting a specific cover hardness optimized for the nip load and paper type, the mill was able to eliminate the barring, achieve a more uniform moisture profile, and improve overall paper quality, reducing customer complaints. Another instance might involve a board machine looking to increase throughput but limited by the drying capacity. Their standard blind hole rolls were achieving decent dewatering, but there was room for improvement. A customized roll designed with a higher void volume and an optimized hole layout for their specific furnish and press configuration resulted in a 2% increase in solids content, allowing the machine speed to be significantly increased without requiring additional drying capacity. These scenarios, common in the industry, underscore how tailoring the blind hole press roll to the specific application can directly address performance bottlenecks and lead to measurable improvements in efficiency, quality, and profitability. It's clear that understanding the specific needs and engineering a bespoke solution is far more effective than relying on general-purpose equipment.

Ensuring Compatibility and Integration of Customized Rolls

Creating a blind hole press roll customized solution isn't just about designing and manufacturing the roll itself; it's also critically important to ensure its seamless compatibility and integration into the existing paper machine. A perfectly designed roll will not deliver optimal performance if it doesn't fit precisely or interact correctly with other machine components. This involves meticulous attention to dimensional accuracy, ensuring the roll fits correctly into the machine frame and bearings. The journals, bearing fits, and coupling points must match the machine's specifications exactly. Furthermore, the customized roll must be dynamically balanced to the operating speed to prevent vibration, as mentioned earlier. This balancing is a precise process, ensuring the weight distribution is uniform around the roll's axis of rotation. Integration also involves considering how the customized roll interacts with showering systems, doctors, and any vacuum boxes in the press section. For example, the blind hole pattern might influence the effectiveness of suction boxes positioned after the nip. Expert consultation during the design phase is essential to foresee and address any potential compatibility or integration challenges. This holistic view, considering the roll as part of a larger, dynamic system, is crucial for successful implementation and unlocking the full benefits of customization. What steps does your mill typically take to ensure new rolls integrate smoothly?

The Role of Expert Consultation in Achieving Perfect Fit and Function

Achieving the full potential of a blind hole press roll customized solution heavily relies on the expertise of the engineers and specialists involved in the consultation and design process. It's not a transaction where you simply order a customized part; it's a partnership focused on solving a specific engineering challenge. Expert consultants bring years of experience working with various paper machines, different paper grades, and a deep understanding of the complex physics involved in press section dewatering. They can accurately diagnose performance issues, recommend the most appropriate materials and cover types, and design a blind hole pattern that is truly optimized for the customer's unique operating parameters. They can also guide the customer on installation best practices and maintenance procedures to ensure the customized roll delivers sustained high performance. Without this expert input, even a seemingly customized roll might not be truly optimized or could even introduce new problems. Many experts agree that the initial consultation and ongoing technical support are just as valuable as the physical roll itself in ensuring a successful outcome. This collaborative approach, combining the mill's operational knowledge with the supplier's engineering expertise, is the bedrock of achieving a perfect fit and function for a customized blind hole press roll, ultimately leading to improved efficiency and profitability.

In conclusion, the concept of a blind hole press roll customized represents a significant opportunity for paper manufacturers to move beyond generic solutions and unlock higher levels of performance and efficiency in their press sections. By tailoring the critical elements of the roll – the blind hole pattern, size, and depth, as well as the roll shell and cover materials – to the specific demands of a particular machine, paper grade, and operating environment, mills can achieve superior dewatering, reduce energy consumption, increase machine speed, improve paper quality, and extend roll life. This requires a meticulous process of analysis, precision engineering, and rigorous quality control, guided by expert consultation. Addressing specific challenges like uneven moisture profiles, vibration, or clogging through bespoke design is a powerful testament to the value of customization. The long-term benefits and attractive ROI underscore that investing in a customized blind hole press roll is not just an expense, but a strategic decision for operational excellence. We understand the complexities of press section optimization and offer tailored solutions designed to meet your unique production needs and challenges.

For more detailed information, please visit our official website: blind hole press roll