In the demanding world of paper manufacturing, where speed, consistency, and throughput are paramount, the performance of machinery components is absolutely critical. At the heart of any paper machine lies a complex system of rolls – guiding, pressing, drying, and calendering the paper web as it forms and dries. Frankly speaking, these rolls are not just passive components; they are active contributors to the entire process. Their design, material, and condition directly impact everything from production speed and paper quality to energy consumption and operational downtime. When we talk about enhancing efficiency in paper mill operations, it's impossible to overlook the fundamental role played by these unsung heroes. subpar or worn-out rolls can lead to a cascade of problems, including sheet breaks, uneven drying, poor calendering, increased maintenance, and ultimately, significant production losses. conversely, investing in and maintaining top-quality paper machine rolls can unlock substantial improvements across the board, streamlining operations and boosting profitability in ways that might not be immediately obvious at first glance. it’s about more than just keeping the machine running; it's about optimizing every turn and nip to achieve peak performance consistently.

Understanding the Vital Role of Paper Machine Rolls in Paper Mill Operations

To truly appreciate how top-quality rolls enhance efficiency, we must first understand their fundamental importance within the intricate ecosystem of a paper machine. From the wet end, where rolls help form and dewater the nascent paper sheet, through the press section, which removes significant amounts of water and consolidates the web, to the dryer section, where steam-heated rolls evaporate remaining moisture, and finally, the calender and reel sections, where the paper is finished and wound – rolls are involved at every single stage. Each roll type has a specific function, and its surface properties, material composition, and structural integrity must be perfectly suited for its intended purpose under extreme conditions of heat, pressure, moisture, and chemical exposure. For example, press rolls require specific coverings to achieve optimal dewatering and prevent picking, while dryer rolls must handle high temperatures and ensure uniform heat transfer. Guiding rolls need to be precisely balanced and smooth to maintain web tension and alignment without damaging the delicate sheet. When any one of these rolls isn't performing optimally – perhaps due to wear, corrosion, or manufacturing defects – the ripple effect on the entire operation can be significant. Imagine a press roll that isn't providing even pressure, leading to inconsistent moisture profiles in the sheet. This inconsistency can cause breaks further down the line, requiring costly shutdowns and startups, or result in a final product that doesn't meet quality specifications, leading to waste. This highlights why the quality of these components is non-negotiable for efficient paper mill operations.

Defining "Top-Quality": What Makes Paper Machine Rolls Stand Out?

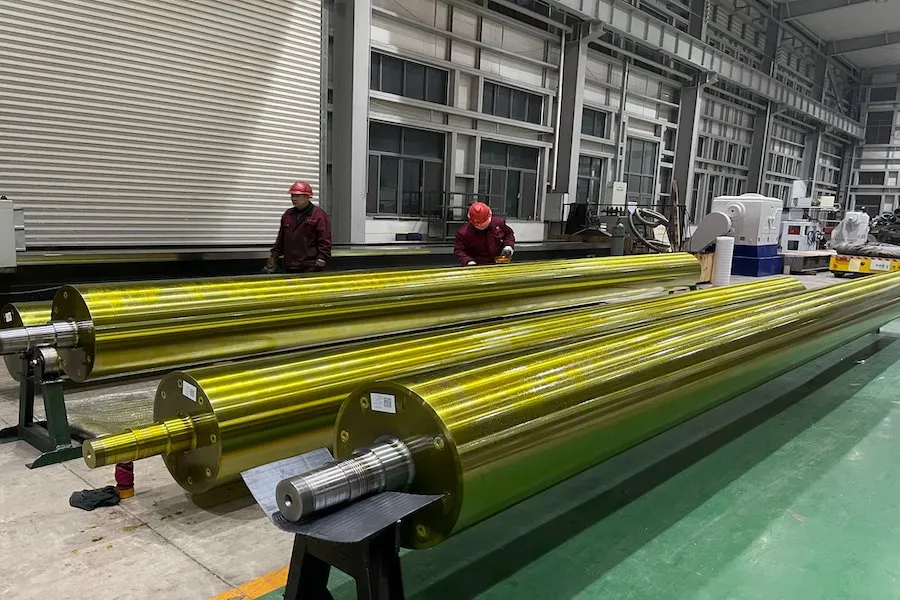

The term "top-quality" when applied to paper machine rolls signifies a combination of factors that go beyond mere functionality. It encompasses precision engineering, superior materials, advanced manufacturing processes, and rigorous quality control. A top-quality roll starts with the right core material, often high-grade steel or cast iron, selected for its strength, stability, and resistance to deflection under load. The design must account for critical factors like thermal expansion, vibration, and bending. The surface treatment or covering is equally important, whether it's a specialized polymer, rubber, ceramic, or metallic coating. These coverings are engineered for specific properties such as wear resistance, release characteristics (preventing paper sticking), heat transfer, and nip uniformity. For instance, a high-release covering on a dryer felt roll can drastically reduce the risk of sheet breaks. Precision machining is crucial to ensure perfect cylindrical shape, straightness, and surface finish, often measured in microns. Balancing is another key aspect; high-speed rotations demand dynamic balancing to minimize vibration, which can cause barring or other defects in the paper. Furthermore, internal components like bearings and journals must be robust and precisely fitted. Interestingly enough, even the seemingly simple process of regrinding and recovering a roll requires specialized expertise and equipment to restore it to "like new" quality. Therefore, "top-quality" isn't just how a roll performs when new, but its ability to maintain that high level of performance consistently over its operational life, minimizing the need for unexpected maintenance and contributing positively to paper mill efficiency. Have you ever considered the level of precision required for a roll spinning at thousands of feet per minute under tons of pressure?

The Direct Link: How Top-Quality Rolls Enhance Efficiency

The connection between top-quality paper machine rolls and enhanced efficiency in paper mill operations is direct and multi-faceted. Efficiency in a paper mill can be boiled down to maximizing throughput of saleable product while minimizing resource consumption (energy, water, raw materials) and unplanned downtime. Top-quality rolls contribute significantly to all these areas. Firstly, their precision and consistent performance lead to fewer web breaks. Sheet breaks are a major source of inefficiency, halting production, requiring manual intervention to re-thread the sheet, and generating significant waste. A single break can cost thousands of dollars in lost production and material. Rolls with optimal surfaces, coatings, and balance minimize stress points on the web and reduce the likelihood of breaks. Secondly, they ensure consistent and optimal dewatering and drying. In the press section, effective dewatering directly reduces the energy required in the dryer section, as removing water mechanically is far more energy-efficient than evaporating it. Top-quality press rolls with proper nip uniformity and efficient coverings maximize water removal. In the dryer section, rolls with excellent heat transfer properties and smooth, clean surfaces ensure uniform drying profiles, preventing bottlenecks or quality issues caused by uneven moisture content. This leads to higher drying speeds and lower energy costs per ton of paper produced. Thirdly, they improve product quality. Consistent roll performance translates directly to consistent paper properties like caliper, moisture profile, smoothness, and strength. Producing right-first-time paper reduces the amount of off-spec product that needs to be recycled or discarded, thus increasing yield and overall efficiency. It’s plain to see that the initial investment in quality pays dividends through reduced waste, lower energy bills, and increased prime production.

Specific Areas of Efficiency Enhancement: Speed, Uptime, and Product Quality

Let's delve deeper into the tangible benefits that top-quality rolls bring to specific aspects of paper mill efficiency. Increased machine speed is a primary goal for many mills, and well-performing rolls are essential for achieving this. Rolls that are precisely balanced, maintain their shape under load, and have appropriate surface properties allow the paper web to run faster and more smoothly without flutter or vibration that could induce breaks. In the dryer section, efficient heat transfer allows for higher web speeds while still achieving the desired moisture content. Frankly speaking, pushing machine speed limits is impossible with unreliable or poorly performing rolls. Uptime is arguably the most critical metric for efficiency. Every minute the machine is stopped for unplanned maintenance, adjustments, or cleaning related to roll issues represents lost production. Top-quality rolls, built with durable materials and coatings, resistant to wear, corrosion, and build-up, require less frequent maintenance and are less prone to unexpected failures. This translates directly into higher operational uptime and increased output. Furthermore, rolls with specific release properties minimize issues like sticking or pilling, which can necessitate frequent cleaning stops. Regarding product quality, the precision and consistency provided by high-quality rolls are non-negotiable. Calender rolls, for instance, are vital for achieving the desired smoothness and caliper; uneven rolls will produce uneven paper, potentially leading to customer rejects. Press rolls determine the consistency of dewatering and density. In my experience, investing in the best possible rolls for critical positions often resolves persistent quality issues that were previously baffling. It allows the mill to produce paper within tighter tolerances more consistently, reducing customer complaints and improving brand reputation, which indirectly but significantly enhances long-term operational efficiency and profitability.

Optimizing Lifespan and Reducing Maintenance through Quality Rolls

Beyond immediate operational gains, top-quality paper machine rolls contribute significantly to long-term efficiency by optimizing their lifespan and reducing overall maintenance burdens. A roll built with superior materials and precision engineering will inherently last longer before requiring major servicing or replacement. This extended operational life reduces the frequency of capital expenditure on new rolls and minimizes the labor and downtime associated with changeouts. Furthermore, high-quality coatings and coverings are designed for durability and resistance to the harsh chemical and physical environments found in a paper machine. This resistance means less wear and tear on the roll surface, reducing the need for frequent grinding or resurfacing. While periodic maintenance is still necessary, top-quality rolls allow for longer intervals between service, scheduling maintenance proactively rather than reacting to unexpected failures. Consider the cost of a roll change: it involves not just the new roll, but also the labor to remove the old one, install the new one, and the significant loss of production time during the shutdown. Reducing the frequency of these events directly boosts overall paper mill efficiency. Moreover, rolls that maintain their performance characteristics over time, such as consistent surface profile and balance, are less likely to cause secondary issues that damage other components or require troubleshooting. I've found that mills that prioritize roll quality often report lower overall maintenance costs and less unplanned downtime compared to those that view rolls as commodity items. It's an investment that pays dividends not just in speed and quality, but in the sheer reliability of the operation.

The Ripple Effect: Impact on Overall Paper Mill Operation and Profitability

The positive effects of utilizing top-quality paper machine rolls extend far beyond the immediate performance metrics of the machine itself, creating a significant ripple effect across the entire paper mill operation and directly impacting profitability. When a paper machine runs more efficiently – with fewer breaks, higher speeds, less downtime, and consistent product quality – it means higher overall throughput of saleable paper. This increased production volume, coupled with reduced waste and lower energy consumption per ton, directly lowers the cost of goods sold. Furthermore, producing consistent, high-quality paper reduces customer complaints and returns, strengthening customer relationships and potentially commanding better market prices. Lower maintenance requirements free up skilled personnel for other critical tasks and reduce expenditures on emergency repairs and replacement parts. Improved uptime allows for better production scheduling and planning, leading to smoother logistics and reduced inventory holding costs. Interestingly enough, even worker morale can be enhanced; operating a stable, reliable machine with fewer frustrating breakdowns makes for a safer and more positive working environment. From a management perspective, enhanced efficiency translates directly into improved profitability and a stronger competitive position in the market. Investing in top-quality rolls is not merely an operational decision; it's a strategic one that underpins the economic viability and future growth potential of the paper mill. It allows the mill to be more agile, responsive to market demands, and ultimately, more successful.

Addressing Paper Machine Roll Challenges with Engineered Solutions

Despite the clear benefits, achieving and maintaining top-quality roll performance presents ongoing challenges for paper mills. Rolls operate under harsh conditions, facing constant wear, corrosion, and thermal stress. Ensuring proper alignment, balancing, and surface integrity over time requires specialized expertise and periodic maintenance. This is where partnering with experienced providers of paper machine roll services and products becomes invaluable. Our company specializes in developing and delivering top-quality paper machine rolls and related services engineered to meet the specific demands of modern paper mill operations. We understand the critical link between roll performance and mill efficiency. Through advanced material selection, precision manufacturing, and innovative coating technologies, we produce rolls designed for maximum durability, optimal performance, and extended service life. Whether it's a new roll engineered for a specific position and speed or the repair and recovery of an existing roll to restore its peak efficiency, our focus is on providing solutions that directly contribute to enhancing your operational efficiency. We offer services that include inspection, grinding, balancing, and applying specialized coverings tailored to resist specific types of wear, chemical attack, or build-up, ensuring your rolls contribute positively to uptime and quality. Our goal is to help you minimize unplanned downtime, reduce maintenance costs, lower energy consumption, and consistently produce paper of the highest quality. Why struggle with frequent breaks and inconsistent quality when engineered solutions for top-quality rolls are available?

Conclusion: The Unmistakable Value of Top-Quality Rolls for Mill Efficiency

In conclusion, the narrative around enhancing efficiency in paper mill operations is inextricably linked to the performance of its paper machine rolls. These components, often overlooked in broader strategic discussions, are fundamental to the smooth, fast, and consistent production of paper. We have explored how defining and achieving "top-quality" in rolls involves precision engineering, superior materials, and advanced manufacturing. More importantly, we have analyzed the direct and significant impact that using such rolls has on operational efficiency – from reducing costly web breaks and maximizing machine uptime to ensuring optimal dewatering, energy usage, and consistent product quality. Investing in rolls that are built to last and perform reliably minimizes maintenance burdens and extends operational life, contributing to lower long-term costs and a more predictable production environment. The benefits cascade throughout the mill, improving overall throughput, lowering operating expenses, enhancing product consistency, and ultimately boosting profitability. For any paper mill serious about optimizing its operations and remaining competitive, prioritizing the selection, maintenance, and quality of its paper machine rolls is not just recommended; it is essential. Top-quality paper machine rolls are, without doubt, a cornerstone for enhancing efficiency in paper mill operations.

For more detailed information, please visit our official website: Paper machine rolls