In the complex world of paper production, achieving the desired surface finish, thickness, and density is paramount. Whether you are producing high-quality printing paper, packaging board, or the softest tissue products like toilet paper, the finishing stages are critical. At the heart of this process lies the calender roll. These heavy, precisely engineered cylinders are responsible for applying pressure and sometimes heat to the paper web, compacting the fibers and smoothing the surface. For demanding applications in tissue production and broader paper milling, particularly where durability and precise performance are non-negotiable, the Steel Calender Roll for Toilet Paper Machines & Paper Mills stands out as an essential component. Its robust construction and tailored surface properties are designed to meet the rigorous demands of continuous, high-speed operation, ensuring consistent paper quality roll after roll. Understanding the technical intricacies and supply chain reliability behind these components is vital for optimizing production efficiency and final product excellence in the paper industry.

Understanding the Core Function of Steel Calender Rolls in Paper Production

What exactly makes a Steel Calender Roll so crucial for operations ranging from vast paperboard mills to specialized toilet paper manufacturing lines? The primary role is calendering – a mechanical finishing process. As the paper web passes through the nip created by a pair of rolls, pressure is applied. This pressure reduces the caliper (thickness) of the paper and improves its smoothness and gloss. Steel is the material of choice for many calendering applications due to its inherent strength, thermal conductivity, and ability to hold a precise surface finish. Unlike other materials that might be used in different parts of the paper machine, steel offers the rigidity needed to maintain a consistent nip pressure across the entire width of the paper web, even under high loads. This consistency is absolutely vital for preventing variations in thickness and finish, which can lead to defects or inconsistencies in the final product. Furthermore, steel allows for various surface treatments, including hard chrome plating or specialized thermal coatings, to enhance durability, wear resistance, and release properties, ensuring optimal performance and longevity even in challenging operational environments.

Technical Specifications and Performance Parameters of Advanced Calender Rolls

Delving deeper into the specifics, the performance of a Steel Calender Roll for Toilet Paper Machines & Paper Mills is defined by several key technical parameters. The material composition of the steel core is selected for its strength and stability. The outer shell requires exceptional hardness and wear resistance, often achieved through specific heat treatments or surface applications. Surface finish is measured in terms of roughness (Ra, Rz), and achieving the correct, often extremely low, values is critical for imparting the desired smoothness to the paper. Roll concentricity and straightness are engineered to micron-level tolerances to ensure even pressure application across the full width. Operating parameters like maximum nip pressure, temperature capacity, and rotational speed are designed to meet the demands of modern, high-speed paper machines. Specialized rolls may incorporate internal heating or cooling systems to control surface temperature, further influencing the paper's properties during calendering. All these specifications work in concert to provide a reliable and effective finishing solution. Manufacturers invest heavily in precision machining and quality control to ensure each roll meets these stringent requirements, guaranteeing optimal performance when installed in a paper machine.

Key Advantages and Competitive Edge of Our Steel Calender Rolls

Choosing the right calender rolls can significantly impact production efficiency and product quality. Our Steel Calender Roll for Toilet Paper Machines & Paper Mills offers distinct advantages engineered to provide a competitive edge. Firstly, the superior metallurgy and precision manufacturing result in exceptional durability and extended service life. This translates directly into reduced downtime for roll changes and lower maintenance costs over time. The ability to maintain extremely tight tolerances on surface finish and geometry ensures consistent paper quality, minimizing waste and improving overall yield. Our expertise allows for tailoring surface treatments – whether it's high-release chrome plating for sticky tissue grades or ultra-smooth finishes for fine printing papers – to perfectly match the specific needs of the application. Furthermore, the design incorporates features that facilitate easier installation and maintenance, such as optimized bearing journals and robust internal structures. For mills seeking reliable components that deliver consistent, high-performance results under demanding conditions, the technical superiority and proven track record of our rolls make them a preferred choice. This focus on quality and longevity ensures a strong return on investment for our clients.

Application Scenarios and Problem Solving in Paper Production

The application of a Steel Calender Roll extends across numerous processes within paper mills and specialized tissue production lines. In the manufacturing of facial tissue or toilet paper, calender rolls are used to impart the final bulk, softness, and smoothness, often requiring specialized non-stick surfaces due to the nature of the paper web. For writing and printing papers, calendering enhances opacity and printability by compacting the sheet and smoothing the surface fibers. In board production, calender rolls help control thickness and improve the surface for subsequent coating or printing. Common problems solved by high-quality calender rolls include uneven paper thickness, poor surface finish, dusting (loose fibers coming off the surface), and web sticking to the rolls. By providing uniform pressure and the correct surface properties, our rolls help eliminate these issues, leading to higher quality output and reduced machine breaks. For complex processes requiring specific finishes, such as achieving a particular level of gloss or bulk on high performance calender rolls for tissue paper, our customizable solutions are designed to meet these precise requirements, optimizing the final product characteristics.

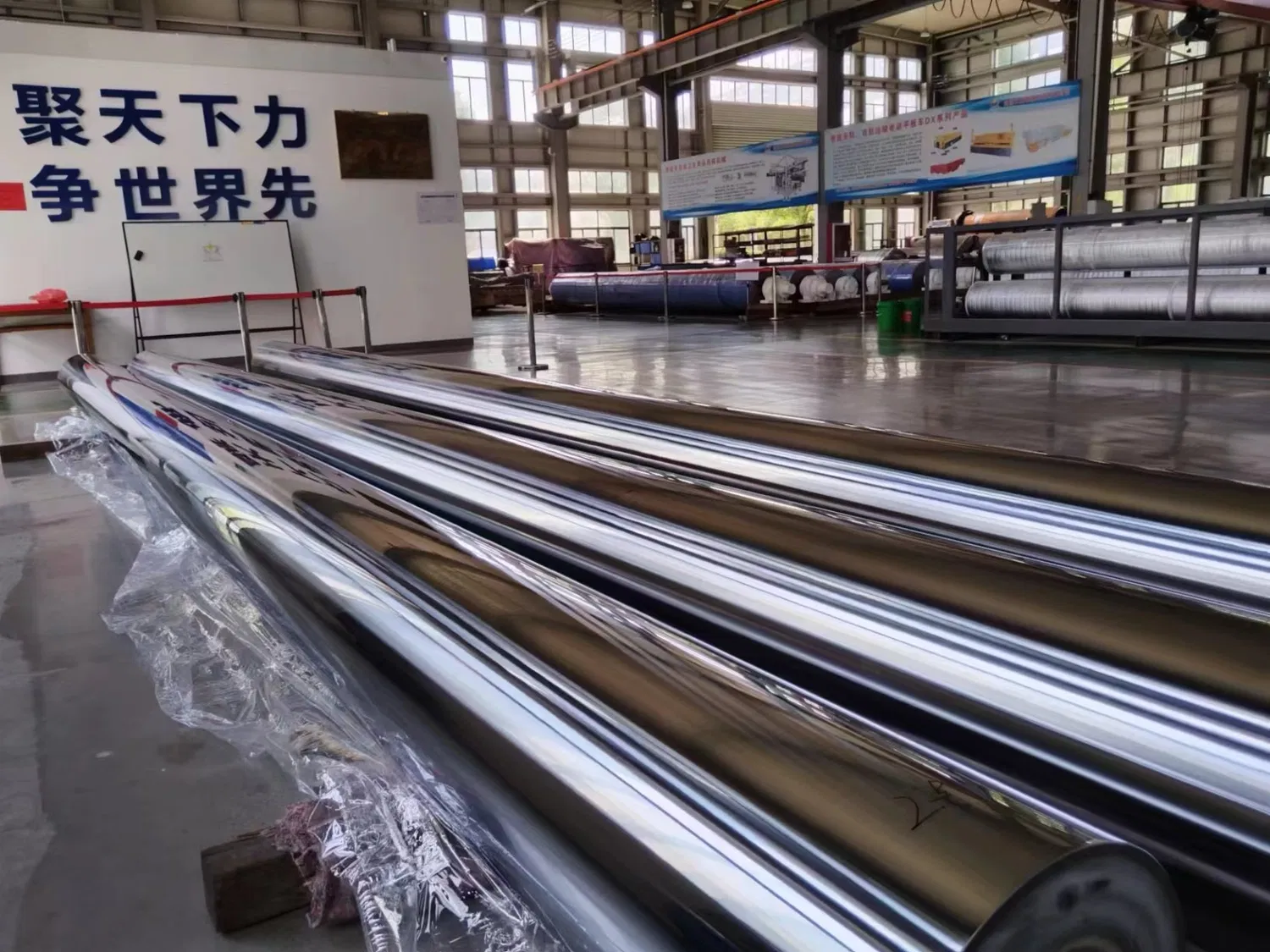

Our State-of-the-Art Manufacturing Processes and Quality Control

The production of a high-precision component like a Steel Calender Roll requires advanced manufacturing capabilities and rigorous quality control. Our facilities are equipped with state-of-the-art machinery, including large-scale lathes capable of handling rolls of significant size and weight, precision grinders that achieve the incredibly fine surface finishes required, and dynamic balancing equipment to ensure smooth operation at high speeds. The manufacturing process begins with the careful selection of high-grade steel alloys. This is followed by forging or casting the roll body, rough machining, heat treatment to achieve the required hardness, and then multiple stages of precision machining and grinding. Surface treatments, such as hard chrome plating or thermal spraying, are applied in controlled environments. Throughout every stage, stringent quality control measures are implemented. This includes dimensional inspections using precision instruments, surface roughness measurement, hardness testing, ultrasonic testing for internal integrity, and final dynamic balancing tests. Adherence to international quality standards, such as ISO certifications, is a fundamental part of our process, ensuring that every Steel Calender Roll leaving our factory meets the highest benchmarks for quality, reliability, and performance. This commitment to excellence is the cornerstone of our manufacturing ethos.

Ensuring Product Reliability and Durability Through Expertise

Reliability and durability are not just features; they are necessities for components operating in the demanding environment of paper mills. A calender roll failure can bring an entire production line to a halt, resulting in significant losses. This is why our focus on engineering and manufacturing expertise is so critical. The inherent strength of the steel core, combined with wear-resistant surface treatments, ensures that our rolls can withstand the constant pressure and friction involved in calendering for extended periods. We carefully consider the specific operating conditions – temperature, humidity, pressure cycles, and the type of paper being processed – when designing and manufacturing each roll. Our engineers utilize advanced simulation and analysis tools during the design phase to predict performance and identify potential stress points, optimizing the roll's structural integrity. Furthermore, our quality control process includes rigorous testing protocols that simulate real-world operating stresses. This comprehensive approach, from material selection through final inspection, ensures that every Steel Calender Roll is built for maximum reliability and exceptional durability, providing peace of mind and predictable performance for our customers in the paper industry, guaranteeing long-term value and minimizing unexpected downtime.

Flexible Supply and Customization Options for Global Clients

Recognizing that paper machines vary widely in design and operational requirements, we offer flexible supply solutions and extensive customization options. Our production capacity is scaled to serve both large industrial paper machine component suppliers and individual mills needing specific replacement parts. We can manufacture Steel Calender Rolls in a wide range of sizes, lengths, and diameters to fit virtually any calendering stack configuration. Customization extends to the surface finish, material properties, and internal design features (like heating/cooling circuits) to meet unique performance specifications. Need a specific surface treatment for a challenging application, such as producing thin, delicate tissue, or perhaps an extra-hard surface for high-pressure board calendering? We work closely with our clients to understand their exact needs and provide tailored solutions. Our goal is to be a responsive and adaptable partner, capable of supplying custom steel rolls for paper finishing that integrate seamlessly into existing machinery and improve overall process efficiency. This flexibility ensures that whether you require a standard replacement or a highly specialized roll, we can provide a product perfectly suited to your application.

Streamlined Purchase Process and Comprehensive Customer Support

Acquiring industrial components, even something as crucial as a Steel Calender Roll, should be a straightforward process. We have developed a streamlined system to support both large business wholesale orders and the needs of individual buyers requiring specialized or replacement rolls. Our team is available to provide expert technical consultation to help you specify the correct roll for your machine and application. We understand that timely delivery is critical, and our logistics network is optimized for efficient global supply, aiming for quick lead times and stable supply chains. For customers considering a significant investment or requiring verification of our capabilities, sample availability can be discussed based on specific requirements. Beyond the initial purchase, our commitment continues with comprehensive after-sales support, including technical assistance for installation and maintenance guidance. We offer diverse payment options to accommodate various business needs. Our focus is on building long-term relationships by providing not only high-quality products like the Steel Calender Roll for Toilet Paper Machines & Paper Mills but also a seamless and supportive customer experience from initial inquiry through the entire operational life of the roll.

In conclusion, the Steel Calender Roll is an indispensable component for achieving optimal finish, thickness, and quality in both toilet paper production and general paper milling operations. Its performance, reliability, and durability are direct results of advanced metallurgy, precision engineering, and rigorous quality control. As a dedicated manufacturer and supplier, we are committed to providing high-quality, customizable rolls that meet the diverse and demanding requirements of the global paper industry. Our expertise ensures that whether you are running a high-speed tissue machine or a large-scale paperboard line, our calender rolls deliver consistent, predictable performance, minimizing downtime and maximizing product quality. We stand ready to partner with businesses and individual clients alike, offering tailored solutions and comprehensive support to enhance your paper production processes. Investing in the right components is key to success, and our Steel Calender Rolls are designed to be a cornerstone of that investment, providing long-term value and superior results. Our commitment to excellence is evident in every roll we produce, ensuring it meets the high standards expected in the industry.

For more detailed information, please visit our official website: Steel Calender Roll for Toilet Paper Machines & Paper Mills