In the complex and energy-intensive world of modern papermaking, achieving optimal efficiency and consistent product quality is paramount. Every stage of the process, from pulp preparation to final winding, plays a crucial role, but perhaps none is as critical for energy savings and quality control as the press section. This is where the paper sheet, after leaving the forming section with a high water content, is subjected to mechanical pressure to remove as much water as possible before reaching the dryers. And within this vital section, the choice of roll material makes a significant difference. For a very long time, and still today in many demanding applications, the granite press roll stands out, offering a suite of advantages that, frankly speaking, remain largely unmatched by alternative materials in certain key performance areas. Its unique properties contribute directly to improved dewatering, enhanced sheet quality, and overall operational efficiency. Why is this age-old material still so relevant and often preferred in sophisticated modern paper machines? Let's dive into the core reasons.

Understanding What Makes Granite Press Rolls Unique for Modern Papermaking

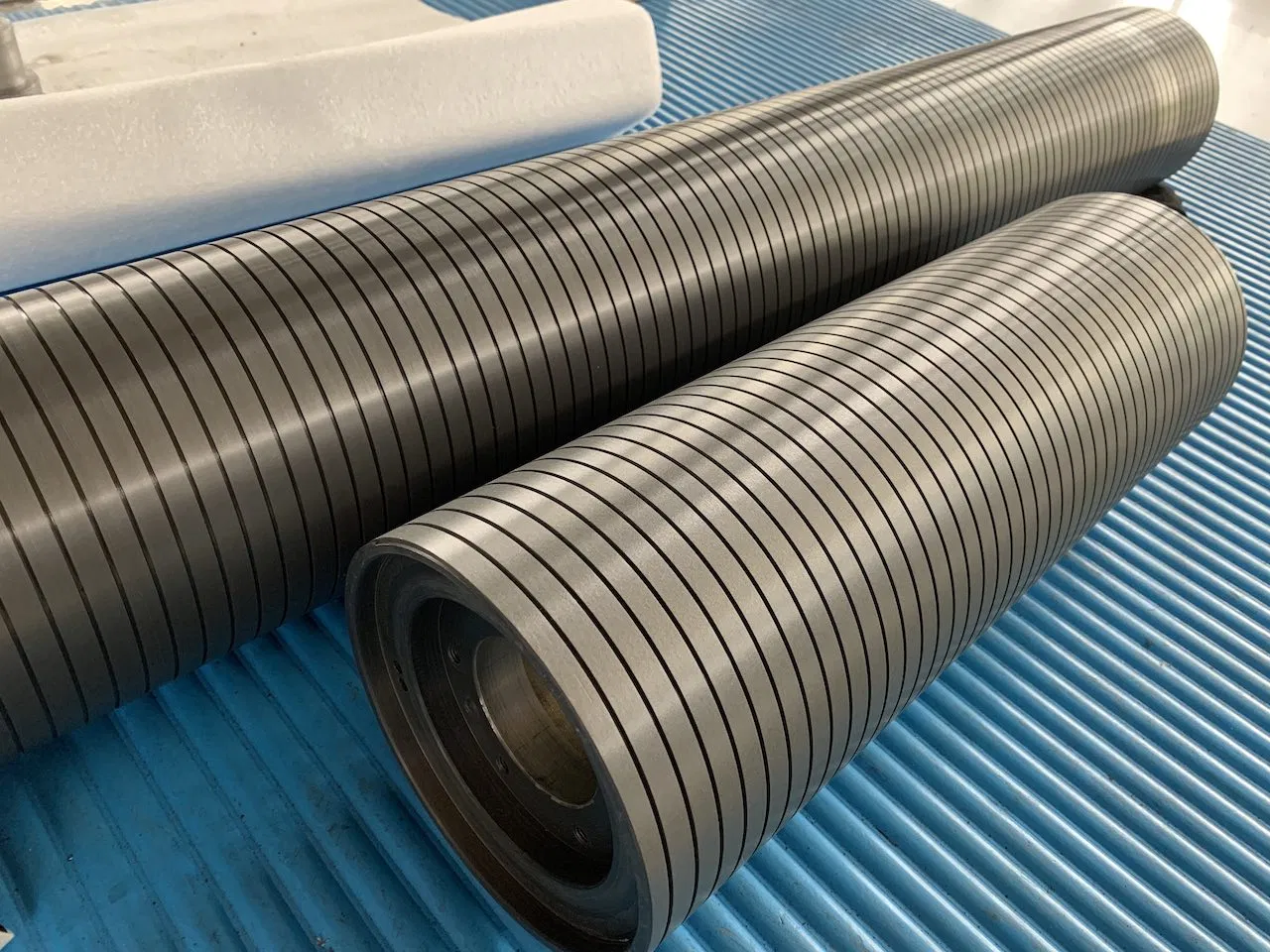

At first glance, granite might seem like a surprisingly traditional choice for a high-tech manufacturing process like modern papermaking. However, the specific geological formation and crystalline structure of the granite used for these rolls provide properties that are difficult to replicate synthetically. We're not talking about just any granite; specialized, dense, fine-grained granite varieties are selected precisely for their homogeneity, hardness, and minimal porosity. This inherent material quality is the foundation upon which all the subsequent advantages are built. Unlike materials that might deform under pressure or succumb quickly to the harsh chemical environment of the papermaking process, granite possesses a natural resilience. Interestingly enough, its ability to maintain a stable, rigid surface under the immense pressures of the press nip is fundamental to its performance. This stability ensures uniform pressure application across the width of the paper web, a non-negotiable requirement for producing paper with consistent thickness and moisture profile. Have you ever considered how a seemingly simple rock can hold such sway in a world of advanced composites and ceramics? It's a testament to its truly unique fitness for purpose in the demanding press section.

Superior Dewatering Efficiency: A Primary Unmatched Advantage of Granite Rolls

One of the most significant benefits derived directly from the properties of granite press rolls is their contribution to superior dewatering efficiency. The press section is where the bulk of mechanical dewatering occurs, reducing the water content from around 80% to typically 40-50% or even lower before the energy-intensive drying section. Every incremental percentage of water removed mechanically saves vast amounts of thermal energy in the dryers, leading to substantial cost reductions. The dense, hard, and smooth surface of a well-maintained granite roll creates an effective nip combined with the opposing roll (often a felt-covered roll). This specific surface allows for efficient transfer of water from the paper sheet into the felt. Moreover, the granite surface itself resists the tendency of water to be reabsorbed back into the sheet as it exits the nip, a phenomenon known as "nip rewetting," which can significantly hinder dewatering efforts. While other materials might offer hardness, the specific surface energy and structure of granite seem particularly adept at minimizing this rewetting effect, directly enhancing the amount of water squeezed out in a single pass. This is a critical factor in the economic viability of modern papermaking operations. Think about the sheer volume of paper produced daily; even a small improvement in dewatering per ton translates into immense energy savings annually.

Exceptional Durability and Longevity: The Economic Edge of Granite Press Rolls

Another key advantage that solidifies the position of granite press rolls in modern papermaking is their remarkable durability and longevity. These rolls operate under extreme conditions – high pressures, elevated temperatures, and a constantly flowing stream of water containing various papermaking chemicals and fillers. Many materials would quickly succumb to abrasive wear, corrosion, or fatigue in such an environment. Granite, however, is inherently resistant to abrasion from paper fibers and fillers, as well as being largely inert to the chemicals typically found in papermaking white water. This means granite rolls can maintain their precise shape and surface finish for extended periods compared to some softer or less chemically stable alternatives. While they do require periodic grinding to maintain perfect cylindricality and surface quality, the intervals between such maintenance are often significantly longer than for other roll types. This longevity translates directly into lower maintenance costs, reduced downtime for roll changes and servicing, and ultimately, a lower total cost of ownership over the lifespan of the paper machine. For production-critical equipment like press rolls, reliability and long service life are incredibly valuable assets, making the initial investment in granite a sound long-term decision for many mills.

Consistent Nip Profile and Paper Quality: How Granite Rolls Ensure Uniformity

Producing a consistent, high-quality paper sheet is the ultimate goal of any papermaking operation, and granite press rolls contribute significantly to achieving this. The rigidity and stability of the granite material ensure that the press nip – the crucial point where the rolls come together and pressure is applied – remains uniform across the entire width of the roll face under operational loads. Any variation in pressure profile across the sheet width can lead to uneven dewatering, resulting in variations in moisture content, caliper (thickness), and density in the final paper product. Such variations can cause problems in subsequent converting processes and negatively impact the paper's performance characteristics. Because granite resists deflection and deformation under pressure so effectively, it helps maintain that vital uniform nip. This consistent pressure profile guarantees uniform dewatering and pressing, leading to a more homogeneous paper web entering the dryers. The result? Paper with consistent physical properties across the reel, which is essential for everything from printing performance to structural integrity. In my experience, achieving this level of uniformity is one of the most challenging aspects of papermaking, and the stable foundation provided by granite rolls is a significant factor in overcoming it.

Resistance to Chemical and Mechanical Wear: Handling the Rigors of Modern Papermaking

Modern papermaking is a demanding process, involving not only mechanical stresses but also exposure to a complex cocktail of chemicals used for pulp treatment, sizing, and water clarification. Press rolls are constantly in contact with this environment. The natural composition of the specialized granite used for press rolls provides excellent resistance to both chemical degradation and mechanical wear. Unlike some metallic surfaces that might be susceptible to corrosion from acidic or alkaline process water, or composite materials that could be affected by certain additives, granite remains largely unaffected. Furthermore, the constant passage of the paper web, containing abrasive fibers and mineral fillers, creates a significant wear challenge for any roll surface. The inherent hardness of granite allows it to withstand this continuous abrasion remarkably well, preserving its critical surface properties and dimensions over time. This combined resistance to chemical attack and mechanical abrasion is a powerful advantage, minimizing the need for frequent surface conditioning or repair and contributing further to the long-term operational reliability of the press section. It's worth noting that maintaining the proper pH and chemical balance in the white water is still important for overall machine health, but granite provides a forgiving and resilient roll surface in this challenging environment.

Surface Properties and Sheet Release: Minimizing Problems in the Press Section

Beyond just dewatering and durability, the specific surface characteristics of granite press rolls also play a crucial role in the smooth operation of the press section. A critical issue in any press is ensuring that the paper web releases cleanly from the roll surface after passing through the nip. If the paper sticks or transfers unevenly, it can lead to web breaks, costly downtime, and lost production. The finely polished surface of a granite roll, combined with its specific surface energy, naturally promotes good sheet release. Unlike some materials that might have a higher affinity for wet paper fibers, granite tends to allow the sheet to peel away cleanly. This property is particularly important at high machine speeds characteristic of modern papermaking, where minimizing web breaks is absolutely essential for maintaining high productivity. While surface coatings and treatments are used on other roll types to improve release, the inherent properties of granite offer a baseline advantage in this regard. Frankly speaking, a roll that promotes reliable sheet release contributes significantly to operational stability and throughput. Do you appreciate how the seemingly small detail of how paper leaves the roll can impact an entire production line?

Addressing Challenges and Sustaining Performance in Modern Papermaking with Granite Rolls

While granite press rolls offer numerous unmatched advantages, like any critical component, they require appropriate care and maintenance to sustain peak performance in the demanding environment of modern papermaking. Maintaining the correct crown profile – the slight taper ground into the roll to compensate for deflection under load – is essential for achieving a uniform nip. Regular inspection and grinding are necessary to correct wear and maintain this profile, as well as to ensure the surface remains smooth and free from imperfections that could affect paper quality or cause web breaks. Keeping the roll surface clean from deposits is also vital for consistent dewatering and release. This is where expertise in handling and servicing these massive, heavy rolls comes into play. Despite their durability, granite rolls are still stone and can be susceptible to catastrophic damage from impact. Therefore, careful handling during installation and removal is paramount. Ensuring that mills have access to reliable partners who understand the specific requirements for manufacturing, maintaining, and servicing granite press rolls is key to maximizing their inherent advantages and achieving the long service life they are capable of providing. Our company understands these nuances deeply.

The Enduring Unmatched Advantages of Granite Press Rolls in Modern Papermaking

In conclusion, despite the advent of new materials and technologies, the granite press roll continues to hold a place of prominence in many modern papermaking applications due to its enduring and often unmatched advantages. Its inherent material properties—density, hardness, chemical resistance, and structural homogeneity—translate directly into tangible benefits in the press section: superior dewatering efficiency leading to energy savings, exceptional durability and longevity resulting in lower operating costs, the ability to maintain a consistent nip profile ensuring uniform paper quality, high resistance to both chemical and mechanical wear, and excellent sheet release properties minimizing disruptive web breaks. While alternative materials have their place, for critical positions requiring the utmost in stability, dewatering performance, and long-term reliability under harsh conditions, granite remains a top choice. The combination of these factors underscores why, even today, granite press rolls are considered an invaluable asset for mills striving for high performance, efficiency, and quality in the competitive landscape of modern papermaking. Investing in and properly maintaining these rolls is an investment in the consistent, cost-effective production of quality paper.

For more detailed information, please visit our official website: Granite press rolls