In the intricate world of papermaking, every component plays a crucial role in the quality and efficiency of the final product. Among these critical elements, the paper machine forming rolls stand out as fundamental. Positioned within the forming section, these rolls are instrumental in the dewatering process, supporting the forming fabric as it carries the pulp slurry. As the fabric passes over these precisely engineered rolls, water drains through the mesh, leaving behind a nascent paper web. The performance of these rolls directly impacts the formation of the sheet, influencing uniformity, strength, and overall quality. A poorly performing forming roll can lead to uneven drainage, fabric wear, and ultimately, production inefficiencies and reduced paper quality. This underscores the importance of selecting reliable, high-performance components from a trusted supplier. Our commitment is to provide such essential parts, including our acclaimed FM-PRO Series paper machine forming rolls, designed to meet the demanding requirements of modern paper production. We understand that papermakers require not just a component, but a solution that contributes to stable, high-speed operations and consistent product output. Our expertise in manufacturing these precision parts ensures that mills can achieve optimal dewatering and sheet formation, setting the stage for subsequent processes in the paper machine.

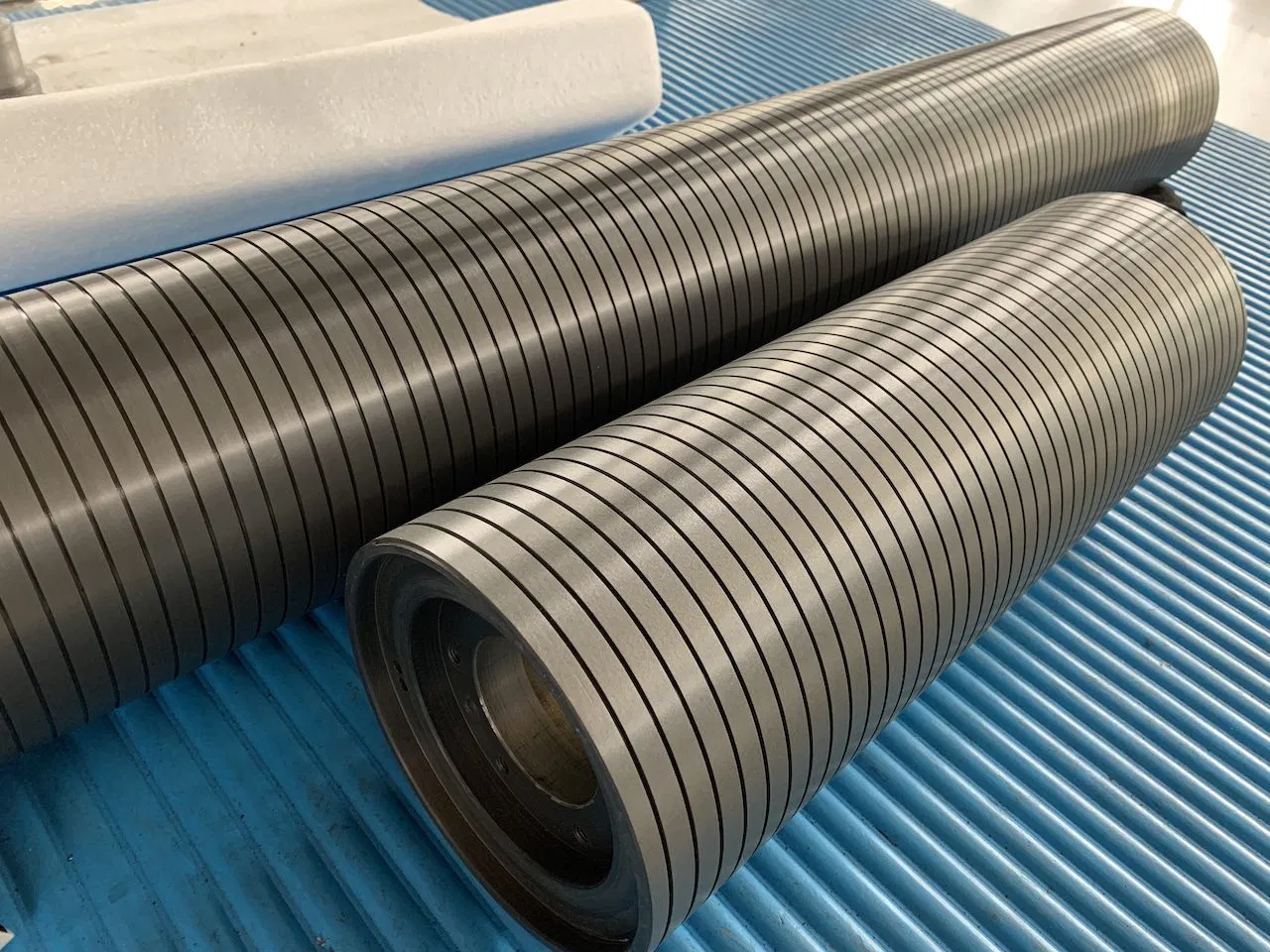

Understanding the technical requirements of paper machine forming rolls is key to appreciating their value. These rolls are subjected to significant loads, high speeds, and a corrosive environment involving water, pulp chemicals, and fluctuating temperatures. Therefore, the materials used in their construction must be robust, corrosion-resistant, and capable of maintaining dimensional stability over time. Typically, these rolls are constructed from high-grade steel, often stainless steel or carbon steel with specialized coatings, to withstand these harsh conditions. The surface finish and concentricity are paramount; any deviation can cause uneven pressure distribution on the fabric, leading to streaks or inconsistencies in the paper web. Furthermore, the internal design of the roll, including bearing supports and internal cooling/heating channels (if applicable), must be engineered for optimal performance and longevity. Rolls may be plain, grooved, or drilled (suction rolls), each serving specific dewatering needs within the forming section. Our manufacturing process meticulously addresses these technical specifications. We employ advanced machining techniques to ensure precise tolerances, superior surface finishes, and perfect balance. Our material selection process is rigorous, choosing alloys and coatings that offer maximum resistance to wear and corrosion, extending the service life of the roll significantly. This technical depth is integrated into every unit we produce, ensuring that our paper machine forming rolls consistently deliver the performance and reliability expected by paper mills worldwide.

Our FM-PRO Series represents the pinnacle of our expertise in paper machine forming rolls technology. These rolls are engineered for maximum efficiency and durability in the most challenging papermaking environments. A core advantage of the FM-PRO Series is its optimized internal structure, designed to facilitate efficient water removal while minimizing energy consumption. The surface treatment applied to these rolls is specifically formulated to reduce friction with the forming fabric, thereby extending fabric life and reducing operational costs associated with frequent fabric changes. Precision balancing is a standard feature, critical for high-speed machines where vibration can lead to machine damage and paper quality issues. The choice of materials for the FM-PRO Series is based on extensive research and field testing, ensuring exceptional resistance to the chemical and abrasive conditions found in the forming section. Furthermore, the design allows for easier maintenance and inspection, reducing downtime. We have received feedback from numerous clients highlighting the significant improvement in dewatering rates and sheet formation consistency after integrating FM-PRO Series rolls into their machines. These rolls are not just components; they are performance enhancers designed to improve the bottom line for paper producers by increasing efficiency, reducing maintenance, and improving paper quality. The modular design also allows for certain degrees of adaptation to existing machine frames, making upgrades smoother and less disruptive.

Reliability and durability are non-negotiable aspects when it comes to critical paper machine components like forming rolls. The cost of unplanned downtime in a paper mill is substantial, making the longevity and consistent performance of every part vital. Our manufacturing philosophy is centered on building paper machine forming rolls that withstand the test of time and demanding operational cycles. We achieve this through a combination of stringent quality control processes, superior material selection, and advanced manufacturing technologies. Every roll undergoes rigorous inspection at multiple stages of production, from raw material sourcing to final surface finishing and balancing. Non-destructive testing methods are employed to detect any potential flaws invisible to the naked eye. The heat treatment and coating processes are carefully controlled to ensure optimal material properties and surface hardness. Our commitment to durability means investing in research and development to continuously improve our designs and manufacturing techniques, anticipating the evolving needs and challenges of the papermaking industry. This dedication to quality ensures that when you install one of our paper machine forming rolls, you can trust it to perform reliably day in and day out, minimizing the risk of unexpected failures and maximizing your machine's uptime. We understand that a durable component is an investment that pays dividends in operational stability and reduced maintenance costs over its lifespan.

The application scenarios for our paper machine forming rolls are broad, spanning various types of paper and board machines. Whether you are producing fine writing paper, newsprint, packaging board, or specialty papers, the forming section's efficiency is paramount, and our rolls are designed to support diverse processes. Different paper grades require specific forming fabric types and drainage profiles, and our range of roll designs—including plain, grooved, and customized patterns—can be tailored to optimize performance for your particular application. For instance, grooved rolls are often used to promote controlled dewatering and reduce fiber disturbance, while suction rolls are critical for achieving higher dryness levels in the forming section. Our expertise allows us to recommend or design the ideal roll configuration for your specific machine type and product requirements. We have successfully supplied rolls for Fourdrinier machines, gap formers, and other modern forming technologies, helping mills solve common problems such as uneven moisture profiles, fabric wear, and sheet formation inconsistencies. Our rolls are engineered to integrate seamlessly into existing machine setups or new installations, contributing to improved runnability and efficiency. We specifically cater to the needs within pulp and paper forming rolls, understanding the unique challenges presented by different fiber types and slurry compositions. Our technical team works closely with clients to assess their specific operational challenges and propose forming roll solutions that address these issues directly, leading to tangible improvements in production.

Behind every high-quality paper machine forming roll is a sophisticated manufacturing operation. Our facilities are equipped with state-of-the-art machinery, including precision CNC lathes, grinders, and balancing machines, capable of handling rolls of various sizes and specifications required for modern paper machines. Our production capacity is substantial, allowing us to fulfill large-scale orders while maintaining consistent quality and adhering to agreed-upon lead times. The manufacturing process is not just about machining; it involves a comprehensive approach encompassing engineering design, material procurement, welding (for fabricated rolls), heat treatment, coating application, and rigorous quality inspection at every stage. We adhere to international quality management standards to ensure that each roll leaving our facility meets the highest benchmarks for performance and reliability. Our team of experienced engineers and skilled technicians oversees the entire process, bringing decades of collective knowledge to bear on every product. This robust manufacturing capability is what enables us to offer not only standard paper machine forming rolls but also highly specialized and custom forming section rolls designed to meet unique machine geometries or performance requirements. We invest continuously in upgrading our equipment and training our personnel to stay at the forefront of manufacturing technology, guaranteeing precision and efficiency in every roll we produce.

Recognizing that no two paper machines are exactly alike, we place a strong emphasis on offering flexible customization options for our paper machine forming rolls. While our standard offerings, including the FM-PRO Series, meet the needs of many applications, we understand that specific machine designs, operational parameters, or desired performance characteristics may require tailored solutions. Our engineering team is adept at working with clients to design and manufacture custom forming section rolls. This includes modifications to dimensions, material grades, surface finishes, grooving patterns, or internal configurations to optimize compatibility and performance within a specific paper machine setup. Whether you need a roll with unique bearing arrangements, specialized coatings for abrasive environments, or a non-standard diameter or face length, we have the capability to deliver. This flexibility extends to supporting both large business wholesale orders for multiple machines or spare parts inventories, as well as catering to individual purchase needs for specific replacements or machine upgrades. Our goal is to be a comprehensive supplier, providing solutions that are precisely matched to our customers' requirements, ensuring optimal fit, form, and function. Offering custom paper machine rolls is a cornerstone of our service, allowing clients to achieve peak performance tailored to their unique operational demands and machine specifications.

Our supply chain is structured for efficiency and global reach, ensuring that our paper machine forming rolls can be delivered to customers wherever they are located. We manage the logistics carefully to ensure timely and secure shipment, minimizing transit times and potential delays. Our established network of shipping partners allows us to navigate international regulations and customs procedures effectively. We maintain a level of finished goods inventory and raw materials that supports quick lead times for standard products, while our manufacturing process is streamlined to expedite the production of custom orders. Stable supply is a key promise; we work closely with our material suppliers to ensure consistent availability of high-quality raw materials, mitigating risks of production bottlenecks. For large projects or ongoing supply agreements, we implement inventory management strategies that align with our customers' production schedules, ensuring that rolls are available precisely when needed. Our global supply capabilities mean that whether you are located in North America, Europe, Asia, or any other major papermaking region, you can rely on us for consistent, dependable delivery of essential paper machine forming rolls. This logistical expertise complements our manufacturing prowess, providing a seamless experience from order placement to installation.

Quality is not just a feature of our paper machine forming rolls; it is embedded in our company culture and processes. We adhere strictly to internationally recognized quality standards throughout our manufacturing and supply chain operations. While specific certifications can vary based on materials and components, our overarching quality management system is designed to ensure traceability, consistency, and continuous improvement. We implement rigorous testing protocols, including dimensional checks, material composition analysis, surface roughness measurements, and dynamic balancing tests for every roll. These tests are conducted using calibrated, high-precision instruments. Meeting and exceeding industry benchmarks for paper machine components is our constant goal. This commitment to quality is our assurance to you that our rolls, including the FM-PRO Series, will perform as specified and expected, contributing to the reliability and efficiency of your paper machine. We understand that the performance of our components directly reflects on the overall output and quality of your paper production, and we take that responsibility seriously. Our dedication to maintaining high quality standards is why paper mills around the world trust us as their supplier for critical forming section components.

We have designed our purchasing process to be straightforward and accessible for both business wholesale clients and individual buyers. Whether you are a large paper mill looking to upgrade multiple machines or a smaller operation needing a single replacement roll, we are equipped to handle your order efficiently. We offer flexible order quantity options, ranging from single units to large production runs. For clients considering a significant investment or requiring specific performance validation, we can often arrange for sample availability, allowing you to assess the quality and fit of our paper machine forming rolls firsthand before committing to a larger order. Our sales team is knowledgeable and ready to assist you with technical specifications, customization options, and logistical details. We aim to provide a responsive and transparent purchasing experience from initial inquiry through order fulfillment. We understand that each customer's needs are unique, and we are committed to providing personalized service that addresses your specific requirements, ensuring you receive the correct rolls for your application with minimal hassle. This commitment to service extends to making the purchase process as simple and adaptable as possible.

Our commitment to our customers extends well beyond the point of sale. We provide comprehensive after-sales support to ensure the successful installation and long-term performance of our paper machine forming rolls. Should you encounter any technical questions or require assistance with commissioning, our experienced support team is available to provide guidance. We can offer advice on installation procedures, operational best practices to maximize roll life, and troubleshooting potential issues. While our rolls, particularly the robust FM-PRO Series, are designed for durability and require minimal maintenance, having expert support available provides peace of mind. We stand behind the quality of our products and are dedicated to ensuring customer satisfaction throughout the entire lifecycle of the roll. Our goal is to build lasting relationships with our clients, acting as a reliable partner in their papermaking operations. We value feedback from our customers as it helps us continuously improve our products and services, ensuring we remain at the forefront of providing high-performance forming section components. This comprehensive support structure is designed to maximize the value you receive from your investment in our forming rolls.

In conclusion, the performance of paper machine forming rolls is paramount to achieving efficient dewatering, consistent sheet formation, and overall paper quality. As a leading manufacturer and supplier, we offer a range of high-quality rolls, including our advanced FM-PRO Series, designed to meet the stringent demands of modern papermaking. Our commitment to technical excellence, robust manufacturing capabilities, flexible customization options like custom paper machine rolls, and dedicated customer support ensures that we provide reliable, high-performance solutions. We are equipped to serve the diverse needs of paper mills globally, whether for standard replacements or highly specialized applications requiring custom forming section rolls for pulp and paper forming rolls processes. Choosing the right forming roll is a critical decision, impacting machine efficiency and profitability. We invite you to explore our offerings and experience the difference that quality, reliability, and expert support can make in your operations. For more detailed information about our products and capabilities, including the full specifications of the FM-PRO Series, please visit our official website: Paper machine forming rolls