The intricate process of paper production relies on a multitude of precisely engineered components working in harmony, and among the most critical are paper machine guide rolls. These essential elements play a vital role in the journey of the paper web as it moves through the various sections of a papermaking machine—from the forming section, through the press and dryer sections, and finally to the reel. Their primary function is to support, guide, and control the tension and path of the continuous paper sheet or felt, ensuring smooth, stable operation at high speeds. Any inconsistency or failure in a guide roll can lead to significant issues, including web breaks, wrinkling, poor sheet quality, and unscheduled downtime, impacting productivity and profitability. Therefore, selecting reliable, high-performance guide rolls is paramount for any paper mill seeking efficiency and consistent quality. Understanding the design, function, and manufacturing quality of these rolls is key to optimizing paper machine performance and reducing operational costs in the long run. Our expertise lies in developing and manufacturing guide rolls specifically engineered for the demanding conditions of paper production, ensuring dependable performance hour after hour, year after year, supporting the vital processes within paper mills around the globe.

Understanding the Critical Role of Paper Machine Guide Rolls in Production

Paper machine guide rolls are not merely passive components; they are active participants in controlling the web's path and tension. As the paper web or forming fabric, press felt, or dryer screen travels through the machine, it interacts with numerous guide rolls. These rolls are strategically positioned to change the direction of the web, maintain proper tension, and prevent sideways movement or wrinkling. In the forming section, breast rolls and couch rolls initiate the web's journey, while subsequent guide rolls direct the fabric. In the press section, guide rolls support the felts that carry the web through dewatering nips. The dryer section utilizes a vast network of guide rolls to support and guide the dryer screens, ensuring optimal contact between the web and heated cylinders for efficient drying. Each roll in the sequence contributes to the overall stability and efficiency of the paper machine. The conditions these rolls operate under are often harsh, involving heat, moisture, corrosive chemicals, and significant mechanical loads. Consequently, their design, materials, and construction must withstand these challenges without compromising performance. The precision of their alignment, surface finish, and dynamic balance is crucial for preventing vibration and ensuring a smooth, unmarked paper surface, which directly impacts the final product quality and machine runnability.

The Importance of Precision and Durability in Guide Roll Design

Precision and durability are non-negotiable requirements for paper machine guide rolls. Precision in manufacturing ensures that the roll is perfectly cylindrical, straight, and balanced, minimizing vibration and uneven wear. A poorly balanced roll can cause vibration that not only damages the roll itself but also affects adjacent components and degrades paper quality through caliper variations or surface imperfections. Durability, on the other hand, is determined by the materials used and the quality of construction. Rolls are typically made from steel, stainless steel, or other alloys, often coated with specialized materials like rubber, ceramics, or polymers to provide specific surface properties—such as friction control, wear resistance, or corrosion protection. The bearings, journals, and internal structure must be robust enough to handle constant rotation under load in a challenging environment. For instance, rolls operating in wet sections require excellent corrosion resistance, while those in the dryer section must tolerate high temperatures. The long service life expected from these components necessitates materials and manufacturing processes that guarantee strength, stability, and resistance to fatigue, wear, and environmental degradation. Investing in high-quality guide rolls from a reliable manufacturer pays dividends in reduced maintenance costs, minimized downtime, and consistently high paper quality, contributing significantly to a mill's operational success and competitive edge in the market.

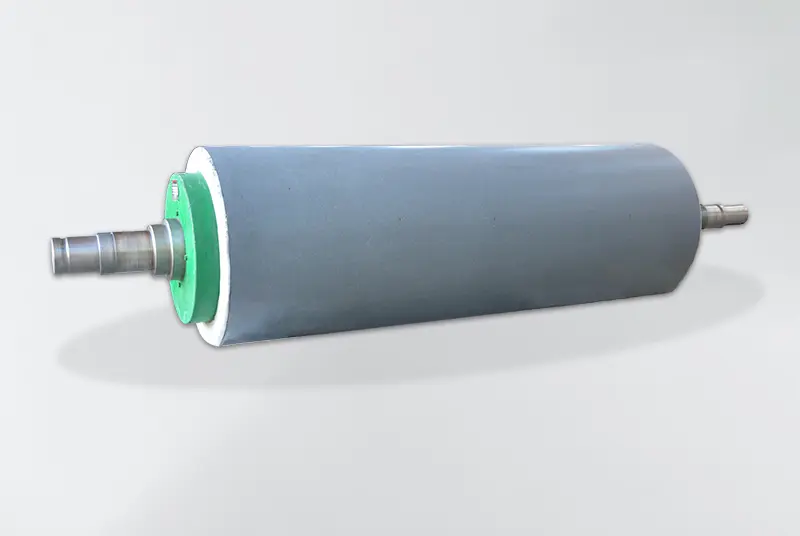

Introducing Our High-Performance Paper Machine Guide Rolls: The ProRoll X200 Series

Understanding the critical demands placed upon these components, we have developed our range of high-performance paper machine guide rolls, including the advanced ProRoll X200 series. This series represents the culmination of extensive research, material science innovation, and precision engineering, specifically designed to meet and exceed the stringent requirements of modern high-speed paper machines. The ProRoll X200 rolls feature robust construction, utilizing high-grade steels or corrosion-resistant alloys as a base, depending on the intended application section (wet end, press, dryer, reel). What sets the ProRoll X200 apart are its optimized surface treatments and internal engineering. Surface options include specialized rubber covers for superior grip and release properties, ceramic coatings for exceptional wear and corrosion resistance, and polished steel finishes for minimal friction and web marking. Each surface is meticulously applied and finished to achieve the desired texture and tolerance. Internally, the rolls are designed for maximum rigidity and minimal deflection under load. They incorporate high-quality, low-friction bearings, often sealed or purged for protection against contamination, ensuring smooth, efficient rotation with reduced energy consumption. The journals are designed for secure mounting and easy maintenance access. We offer the ProRoll X200 in a wide range of diameters and face lengths to accommodate various machine configurations and application needs, ensuring a perfect fit and optimal performance within your specific setup, providing a reliable and efficient solution for your paper production line.

Technical Specifications and Performance Parameters of the ProRoll X200

The technical specifications of the ProRoll X200 series are engineered to deliver exceptional performance and longevity in demanding paper machine environments. Typical specifications include customizable roll diameters ranging from 150mm to over 1500mm, with face lengths extending up to 12,000mm or more, tailored to match the specific width requirements of your paper machine. The roll shells are fabricated from precision-machined steel or stainless steel tubing, ensuring concentricity and straightness within tight tolerances. Depending on the application, shell thickness is optimized to provide sufficient rigidity while minimizing weight. Dynamic balancing is performed to ISO quality grades (typically G2.5 or G6.3, or even G1 for critical high-speed applications) at operational speeds to eliminate vibration and ensure smooth running. Load capacity varies based on diameter, wall thickness, and journal design but is engineered to safely exceed typical operating loads encountered in paper machines. Surface hardness and roughness are carefully controlled, especially for coated rolls, to provide optimal web interaction—preventing slipping, stretching, or marking. For example, rubber covers can have specified durometer hardness and groove patterns, while ceramic surfaces boast Vickers hardness ratings suitable for extreme wear conditions. Operating temperature ranges are also considered; rolls for dryer sections are designed to withstand temperatures up to 150°C or higher, while wet end rolls are optimized for corrosion resistance in humid, chemical-rich atmospheres. These detailed parameters collectively ensure that each ProRoll X200 guide roll delivers consistent, reliable performance under the unique stresses of its specific location on the paper machine.

Advantages and Core Competitiveness of Our Paper Machine Guide Rolls

Choosing our paper machine guide rolls, including the ProRoll X200, provides distinct advantages that contribute directly to improved paper machine performance and overall profitability. Our core competitiveness stems from a combination of superior design, quality materials, precision manufacturing, and a deep understanding of the papermaking process. The durability and reliability of our rolls mean significantly reduced instances of unexpected failures and downtime, which are costly disruptions in paper production. Their precise balance and surface finish minimize vibration and web defects, leading to consistently higher quality paper with fewer rejects. The optimized bearing systems and roll construction contribute to smoother running, potentially reducing energy consumption compared to less efficient rolls. Furthermore, our ability to customize specifications—from dimensions and materials to specialized coatings—ensures that you receive a roll perfectly suited to your specific machine geometry and operational requirements. This tailored approach maximizes performance and extends the lifespan of the roll in its intended application. We don't just supply rolls; we provide engineered solutions designed to enhance the efficiency, reliability, and quality output of your paper machine, helping you achieve greater productivity and a stronger return on your investment in critical components like guide rolls. This focus on delivering tangible operational benefits is what truly sets our products and services apart in the market.

Ensuring Reliability and Longevity in Demanding Paper Mill Conditions

Reliability and longevity are paramount when operating in the challenging environment of a paper mill. Guide rolls are constantly subjected to high temperatures, corrosive chemicals, high humidity, dust, fiber particles, and significant mechanical stress from web tension and roll weight. Our manufacturing process and material selection are specifically geared towards ensuring that our paper machine guide rolls, including the ProRoll X200, withstand these harsh conditions over extended periods. We utilize advanced welding techniques, stress relieving, and heat treatments to ensure the structural integrity and dimensional stability of the roll shell and journals. High-quality bearing selection and mounting procedures are critical; we often incorporate features like specialized seals, labyrinth designs, or automatic lubrication systems to protect bearings from contamination and moisture ingress, which are common causes of premature failure in humid paper mill environments. Surface coatings, whether rubber, ceramic, or composite, are chosen not only for their functional properties (grip, release, wear resistance) but also for their adhesion strength and ability to withstand the chemical and thermal stresses of the process. Rigorous inspection and testing at every stage of production—from raw material verification to final dynamic balancing and dimensional checks—guarantee that each roll meets our high standards for durability and reliable performance. This meticulous attention to detail in design and manufacturing is the foundation of the exceptional longevity you can expect from our guide rolls.

Manufacturing Excellence and Quality Assurance for Paper Machine Guide Rolls

Our capability as a leading manufacturer of paper machine guide rolls is built upon a foundation of manufacturing excellence and rigorous quality assurance processes. We operate state-of-the-art machining facilities equipped with large-scale lathes, grinding machines, and dynamic balancing equipment capable of handling rolls of significant size and weight with exceptional precision. Our manufacturing team comprises experienced engineers and skilled technicians who understand the nuances of roll fabrication for the paper industry. Quality control is integrated into every step of the production cycle, starting with the careful selection and inspection of raw materials, ensuring they meet required metallurgical specifications. Throughout the machining, welding, coating application, and assembly phases, various checks are performed, including dimensional measurements, surface finish analysis, ultrasonic testing for material integrity, and non-destructive testing of welds. Before shipment, every paper machine guide roll undergoes final inspection, including comprehensive dynamic balancing tests performed to industry standards at speeds simulating operational conditions. These stringent quality control measures ensure that each roll leaving our facility is free from defects, meets all specified technical parameters, and is ready for immediate and reliable service in your paper machine. Our commitment to quality is not just about meeting standards; it's about exceeding expectations to deliver components that contribute to your operational success, giving you peace of mind in the performance and durability of our guide rolls in the demanding environment of paper production.

Precision Manufacturing Processes and Advanced Equipment

Achieving the precision required for high-speed paper machines demands sophisticated manufacturing processes and advanced equipment. Our workshop houses large-capacity CNC lathes capable of machining roll bodies with micron-level precision, ensuring perfect straightness and concentricity along the entire face length. Grinding machines with specialized abrasive wheels are used to achieve the exact surface finish and desired crown profile (if required) on the roll surface, critical for web control and dewatering efficiency in certain applications. For balancing, we employ modern dynamic balancing machines that can accurately measure and correct imbalances in rolls weighing many tons, simulating operational speeds to ensure smooth running at the machine's actual operating velocity. The application of specialized coatings, whether rubber covering, hard chrome plating, or thermal spray ceramics, is performed in controlled environments using advanced techniques to ensure uniform thickness, optimal adhesion, and the desired surface properties. Our welding processes are carefully controlled to minimize distortion and internal stresses in the roll structure. This combination of skilled craftsmanship, advanced technology, and meticulous process control enables us to produce paper machine guide rolls that meet the tightest dimensional tolerances and performance specifications, guaranteeing reliable integration and operation within any paper machine configuration, showcasing our capability as a professional supplier for this crucial industry.

Customization Capabilities and Global Supply Chain

Recognizing that every paper machine is unique and often requires tailor-made solutions, we offer extensive customization capabilities for our paper machine guide rolls. While our standard ranges, like the ProRoll X200 series, cover a wide array of common specifications, we excel at producing rolls designed specifically for your particular machine layout, process parameters, and performance goals. This includes manufacturing rolls with custom diameters, face lengths, journal configurations, bearing types, and specialized shell materials or coatings. Whether you need a roll with a specific crown profile for moisture leveling in a press nip, a highly corrosion-resistant roll for a bleached pulp line, or an extremely lightweight roll for a high-speed section, our engineering team works closely with you to develop the optimal design. We can also reverse-engineer existing rolls or design replacements based on your technical drawings and operational requirements. Our global supply chain and logistics network are established to efficiently deliver custom and standard paper machine guide rolls to paper mills anywhere in the world. We manage the entire process, from production scheduling and quality inspection to packaging and international shipping, ensuring your rolls arrive safely and on time, ready for installation. This flexibility in manufacturing combined with reliable global delivery makes us a trusted partner for paper producers seeking both standard and specialized roller solutions.

Offering Tailored Solutions for Specific Paper Machine Requirements

Providing tailored solutions is a key aspect of our service. Paper machines, particularly older ones or those with unique configurations, often require guide rolls with specific dimensions or features that are not standard catalogue items. Our engineering team possesses deep knowledge of paper machine design and operation, allowing us to assist you in defining the precise specifications needed for a replacement or upgrade roll. We consider factors like the intended location on the machine, the type of web or felt/fabric being guided, operating temperature, load conditions, and required surface properties. Based on this information, we recommend the most suitable materials, coatings, and design features. For instance, rolls for the wet end might benefit from specialized stainless steel alloys or composite materials combined with corrosion-resistant coatings, while dryer section rolls require materials and bearing designs capable of handling high temperatures and thermal expansion. We can also incorporate features like internal cooling or heating, specific balancing requirements for ultra-high speeds, or integration with existing machine control systems if necessary. This consultative approach ensures that the custom paper machine rolls we manufacture are not just replacements but optimized components that enhance your machine's performance and reliability, addressing the unique challenges of your specific paper production process and equipment setup effectively.

Supporting Your Purchase: From Business Wholesale to Individual Needs

As a professional paper machine guide rolls supplier, we understand that our customers range from large multinational paper corporations requiring bulk wholesale orders to smaller mills or individual technicians needing a single replacement roll. Our business model is structured to support both ends of this spectrum with flexibility and dedicated service. For large business purchases, we offer competitive wholesale pricing, volume discounts, and the capacity to manage large batch production runs while maintaining consistent quality across the entire order. We work closely with procurement teams to establish long-term supply agreements, predictable lead times, and streamlined logistics. However, we also recognize the importance of supporting smaller or individual purchase needs. Whether you require a single custom roll for a critical position on one machine or several standard rolls for a specific project, we are equipped to handle your order efficiently. There are no rigid minimum order quantities that prevent smaller businesses from accessing the high-quality paper machine guide rolls they need. We aim to make the process of purchasing our products straightforward and accessible for all types of customers, providing the same level of technical support and attention to detail regardless of order size, ensuring that every customer receives the high-quality components and support required to keep their paper machine running smoothly and efficiently.

Flexible Ordering and Comprehensive After-Sales Support

Providing a flexible ordering process is part of our commitment to customer satisfaction. We are prepared to discuss your needs whether you have complete technical drawings, just a list of specifications, or simply need to replace a damaged roll and require assistance in identifying the correct type and dimensions. Our sales and engineering teams are available to provide technical consultation, helping you specify the ideal paper machine guide rolls for your application. We offer options for discussing specifications, providing quotations, and processing orders through various channels. For potential customers interested in evaluating our quality or testing a specific design, sample availability can be discussed depending on the complexity and type of roll required. Beyond the initial purchase, our commitment continues with comprehensive after-sales support. We provide guidance on installation, alignment, and maintenance best practices to ensure the longevity and optimal performance of the rolls. Should any issues arise during operation, our technical support team is available to provide assistance and troubleshooting. We stand behind the quality and durability of our products, including the ProRoll X200 series, and are dedicated to ensuring your satisfaction throughout the lifespan of the roll. This ongoing support ensures that your investment in our paper machine guide rolls delivers sustained value and contributes to the continuous operation of your paper machine without unexpected interruptions or performance degradation issues, reinforcing our position as a reliable supplier.

Investing in Performance: The Long-Term Value of Quality Guide Rolls

While the initial cost of high-quality paper machine guide rolls might be higher than lower-grade alternatives, it's crucial to consider the long-term value they provide. Investing in durable, reliable components like our ProRoll X200 series is an investment in the consistent performance and profitability of your entire paper machine operation. The costs associated with guide roll failure extend far beyond the price of a replacement roll. Unscheduled downtime due to a failed roll can cost thousands or even tens of thousands of dollars per hour in lost production. Frequent maintenance, bearing replacements, or roll regrinding add up significantly over time. Furthermore, poor quality rolls can contribute to web breaks, paper quality defects (like marking or uneven moisture profiles), and increased wear on other machine components, all of which impact efficiency and profitability. High-quality guide rolls minimize these risks. Their extended service life reduces the frequency of replacements and maintenance interventions. Their stable, vibration-free operation contributes to consistent paper quality and higher machine speeds. Their robust construction withstands the demanding environment, preventing premature failures. Therefore, choosing paper machine guide rolls based purely on the lowest upfront price is often a false economy. The long-term cost of ownership, factoring in reliability, lifespan, maintenance, and impact on production efficiency and paper quality, overwhelmingly favors the investment in high-performance, quality-manufactured rolls, making them a wise choice for any paper mill focused on sustainable operations and profitability.

Ensuring Uptime and Efficiency with Reliable Components

Ultimately, the goal of any paper mill is to maximize uptime and efficiency while producing high-quality paper. Reliable components are the backbone of achieving this goal. Guide rolls, being integral to the web path and tension control, directly impact machine runnability. A guide roll that performs reliably minimizes the risk of web breaks caused by uneven tension, misalignment, or surface issues. A durable roll reduces the need for frequent maintenance or replacement, keeping the machine running consistently. Efficient guide rolls, with smooth-running bearings and optimized surfaces, can contribute to reduced energy consumption and lower operating temperatures, further enhancing overall efficiency. By providing dependable paper machine guide rolls engineered for longevity and performance, we contribute to the smooth, uninterrupted operation of your paper machine. This focus on reliability translates directly into more production time, reduced maintenance costs, improved paper quality, and ultimately, increased profitability for your mill. Our commitment is to supply components that you can trust, allowing you to focus on optimizing your paper production process rather than dealing with component failures or performance issues. Whether you require a standard replacement or a highly specialized custom roll, partnering with us ensures you receive guide rolls designed and built for the rigorous demands of continuous paper production, helping you maintain consistent uptime and high levels of operational efficiency day in and day out.

In conclusion, paper machine guide rolls are indispensable components whose quality and performance significantly influence the efficiency, reliability, and output quality of a paper machine. From guiding the delicate web through the forming section to supporting the process in the high-temperature dryer sections, these rolls face challenging conditions that demand precision engineering, robust materials, and reliable manufacturing. Our range of paper machine guide rolls, including the advanced ProRoll X200 series, is designed and manufactured to meet these rigorous demands, offering superior durability, reliable performance, and contributing to improved uptime and paper quality. As a dedicated supplier and manufacturer, we offer extensive customization options, supported by advanced production capabilities and stringent quality control, catering to both large-scale business wholesale needs and individual purchase requirements globally. By choosing high-quality, reliable guide rolls, paper mills make a strategic investment in their operational efficiency and long-term profitability, minimizing costly downtime and maximizing production output with consistent quality. We are committed to providing the high-performance components and expert support needed to keep your paper machine running smoothly and efficiently.

For more detailed information, please visit our official website: Paper machine guide rolls