In the intricate and demanding process of modern papermaking, every component plays a critical role in ensuring efficiency, quality, and ultimately, profitability. Among the most vital elements within the paper machine is the press section, and at its heart lie the paper machine press rolls. These rolls are not merely cylindrical structures; they are precision-engineered instruments subjected to immense pressure, high temperatures, and continuous friction, all while operating at high speeds. Their primary function is the crucial task of dewatering the paper web, removing a significant portion of water content before the drying section. This dewatering process directly impacts the energy consumption of the subsequent drying phase, making the performance and reliability of press rolls absolutely paramount to the overall energy efficiency and speed of the paper machine. A well-designed and properly functioning press roll can dramatically reduce drying costs and increase production rates. Conversely, a poorly performing roll can lead to uneven moisture profiles, sheet breaks, reduced paper quality, and costly downtime. The technology behind these rolls, including the materials used for their cores and covers, the internal design for cooling or heating, and the precision of their crowning and balancing, represents decades of research and development aimed at maximizing efficiency and durability under challenging conditions. Our company understands this critical importance and specializes in the design, manufacture, and supply of high-performance paper machine press rolls, engineered to meet the rigorous demands of contemporary paper production environments across various grades and machine types.

The demands placed upon paper machine press rolls are multifaceted and incredibly taxing, pushing the boundaries of material science and mechanical engineering. During operation, the paper web passes through the nip created by two or more press rolls, where mechanical pressure is applied to squeeze water out of the fiber structure. This pressure can be substantial, often measured in hundreds of kilonewtons per linear meter (kN/m), equivalent to tons per linear inch. Beyond static pressure, the rolls experience dynamic forces at high rotational speeds, necessitating exceptional structural integrity and precise dynamic balancing to prevent vibrations that could compromise sheet quality or machine stability. The operating environment is also harsh, involving elevated temperatures, moisture, and exposure to various chemicals used in the papermaking process, including sizing agents, fillers, and potentially corrosive substances. The cover material, in particular, must be able to withstand abrasive wear from the paper web and felt, resist chemical degradation, maintain its mechanical properties (hardness, elasticity) consistently across the roll face, and facilitate effective water removal without picking or disturbing the delicate paper web. Different paper grades and machine configurations require specific types of press rolls, utilizing various core materials like cast iron, steel, or composite materials, and a wide array of cover materials including rubber, polyurethane, granite, or specialized composites, each selected for its suitability to particular operating conditions and paper types. The choice of cover material is critical for maximizing paper machine dewatering efficiency and ensuring optimal performance.

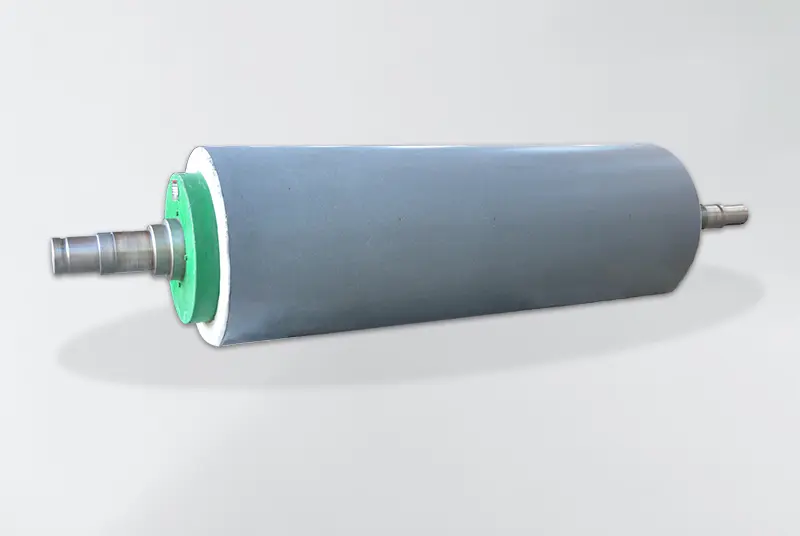

Engineered Excellence: The ProRoll 5000 Series

Our commitment to innovation and quality culminates in our flagship product line, the ProRoll 5000 series of paper machine press rolls. This series represents the pinnacle of our engineering expertise, designed to deliver unparalleled performance, durability, and efficiency in the most demanding paper machine applications. The ProRoll 5000 is available in various configurations, tailored to specific press section layouts and paper grades, including suction press rolls, blind-drilled press rolls, grooved press rolls, and solid press rolls with advanced composite covers. Each roll in the series is built upon a robust core structure, typically fabricated from high-grade steel or composite materials, selected for its strength and resistance to bending under extreme loads. The precision of the core manufacturing is paramount, ensuring concentricity and straightness within tight tolerances. What truly sets the ProRoll 5000 apart is its range of advanced cover technologies. We offer a variety of proprietary cover compounds, developed through extensive research, that provide superior wear resistance, optimal nip profiles for efficient dewatering, excellent chemical compatibility, and consistent performance over extended periods. These covers are applied using advanced techniques like thermal spraying or casting, ensuring a perfect bond to the core and uniform thickness across the face. The internal design of the ProRoll 5000 can include provisions for cooling or heating mediums, essential for controlling roll temperature and optimizing cover performance, especially in high-speed or high-temperature applications. Every aspect of the ProRoll 5000 series is engineered for performance.

Beyond the selection of materials and basic configuration, the technical specifications and performance parameters of the ProRoll 5000 series are meticulously controlled to meet and exceed industry standards. We offer rolls capable of operating at machine speeds exceeding 2000 meters per minute (m/min), with nip pressures reaching up to 400 kN/m or more, depending on the specific model and application. The maximum operating temperature tolerance varies by cover type, but our advanced composite covers are designed to withstand temperatures commonly encountered in press sections. The diameter and face length of the ProRoll 5000 are fully customizable to match the exact dimensions of your paper machine, ensuring a perfect fit and seamless integration. Critical parameters such as dynamic balance are achieved to extremely tight tolerances, typically G1.0 or better according to ISO standards, minimizing vibration and ensuring smooth, stable operation at high speeds. The cover hardness, elasticity, and surface finish are precisely controlled during manufacturing and rigorously tested to guarantee the desired nip behavior and water removal characteristics. For grooved or drilled rolls within the ProRoll 5000 series, the pattern density, depth, and angle are optimized based on fluid mechanics principles to maximize water removal efficiency and minimize rewetting of the sheet after the nip. The engineering detailed in the ProRoll 5000 ensures consistent, high-level performance.

Cutting-Edge Manufacturing and Rigorous Quality Control

Our ability to consistently produce paper machine press rolls of exceptional quality, including the demanding specifications of the ProRoll 5000 series, stems from our investment in state-of-the-art manufacturing facilities and our unwavering commitment to stringent quality control processes. Our production capacity is substantial, allowing us to handle large-scale orders while maintaining efficient lead times. Our facilities are equipped with advanced machinery, including large-capacity CNC lathes for precise core machining, sophisticated dynamic balancing machines capable of handling rolls of varying sizes and weights, and specialized grinding and polishing equipment to achieve the exact surface finish and crowning profile required for optimal performance. The application of roll covers is a critical step, utilizing automated systems for techniques such as thermal spraying, which ensures a homogeneous and dense cover layer, or advanced casting methods for polymer covers, guaranteeing uniform properties throughout the cover thickness. Every raw material entering our facility undergoes rigorous inspection to verify its composition and quality. Throughout the manufacturing process, multiple checkpoints are established to monitor key parameters. Core dimensions, concentricity, and runout are checked at various stages. The cover application is monitored for thickness, bond strength, and uniformity. After the cover is applied, the roll is ground to the specified diameter and crowning profile, with precision laser measuring systems used to verify the accuracy of the profile across the entire roll face. Finally, every finished roll undergoes dynamic balancing to ensure smooth operation at high speeds, a crucial step in preventing vibrations and maximizing extending lifespan of paper machine press rolls.

Our commitment to quality extends beyond manufacturing and testing; it is embedded in our culture and processes. We adhere to internationally recognized quality management systems, such as ISO 9001, ensuring that our operations are systematic, documented, and continuously improved. Material sourcing is carefully managed, working only with trusted suppliers who meet our high standards. Detailed manufacturing records are maintained for every roll produced, providing full traceability from raw materials to the finished product. Non-destructive testing methods, such as ultrasonic testing or dye penetrant testing, may be employed to inspect the integrity of the core and cover bond, ensuring there are no hidden defects that could compromise performance or safety. We also perform rigorous performance testing where applicable, simulating operational loads and speeds to validate the roll's capabilities. The crowning of a press roll is a particularly critical parameter, as it compensates for the deflection of the roll under nip pressure, ensuring a uniform pressure profile across the web width. Our grinding equipment and measurement systems are capable of achieving complex crowning profiles with extremely high accuracy, essential for maximizing paper machine dewatering efficiency and producing a uniform moisture profile in the paper web. This meticulous attention to detail at every stage of production guarantees that our paper machine press rolls, including the ProRoll 5000 and custom configurations, meet the highest standards of quality and reliability before they leave our facility.

Applications, Solutions, and Flexibility

The versatility of our paper machine press rolls allows them to be successfully integrated into a wide array of paper machine types and configurations, serving various segments of the paper industry. Our rolls are utilized in machines producing graphic papers such as newsprint, printing, and writing papers, where surface finish and uniformity are critical. They are essential components in machines manufacturing packaging grades like linerboard, fluting, and boxboard, where strength and dewatering capacity are paramount. Furthermore, our specialized rolls are used in tissue and towel machines, which demand covers capable of gentle yet effective dewatering on very lightweight and delicate webs, often involving specific requirements for custom press rolls for tissue machines. Whether it's a high-speed fine paper machine or a slow-speed board machine, we have a press roll solution engineered for the specific challenges and requirements of that application. Our rolls are designed not only to perform their primary dewatering function effectively but also to solve common problems encountered in the press section. These include mitigating sheet barring caused by vibration or uneven pressure, preventing picking or sticking of the paper web to the roll surface, reducing cover wear, and contributing to lower energy consumption by improving dewatering efficiency and reducing the load on the dryer section. By focusing on robust design and appropriate material selection, our press rolls contribute significantly to increased machine uptime, reduced maintenance costs, and improved overall paper quality. We offer solutions for optimizing paper machine dewatering across the board.

Understanding that every paper machine is unique, with specific operational parameters and historical performance data, we emphasize flexibility in our offering. We cater to both large-scale business wholesale clients requiring multiple rolls for new machine builds or comprehensive rebuilds, and individual buyers needing a single replacement roll or a specialized roll for a specific section upgrade. Our manufacturing process is designed to accommodate flexible order quantities, from single custom units to volume production runs. Customization is a core strength; we don't just offer standard sizes. We can engineer and manufacture paper machine press rolls, including variants of the ProRoll 5000, to precise customer specifications, including unusual diameters, face lengths, specific crowning profiles (parabolic, polynomial, or custom curves), unique drilling or grooving patterns, and internal features for heating or cooling systems. The choice of cover material can be tailored to the exact paper grade, machine speed, operating pressure, and chemical environment of your specific press section. Our engineering team works closely with clients to understand their needs and recommend or design the optimal press roll solution. This includes providing guidance on selecting press roll covers for specific paper grades to maximize performance and lifespan. We believe in providing solutions that are not only high-performing but also perfectly matched to your unique operational context, whether you are a large corporation or a smaller independent mill operator, ensuring both business wholesale and individual purchase needs are met with the same level of expertise and service.

Global Reach and Dedicated Support

As a global supplier, we have established a reliable supply chain and logistics network capable of delivering our paper machine press rolls to customers around the world efficiently and securely. We understand that downtime is extremely costly in the paper industry, and timely delivery of replacement or new rolls is critical. Our production planning and logistics teams work in coordination to ensure quick lead times wherever possible and maintain a stable supply of our products, from standard configurations to highly customized units. We utilize robust packaging methods specifically designed for the size, weight, and precision of press rolls, protecting them during transit via various modes of transportation – sea, air, or land freight. Our experience in international shipping allows us to navigate customs procedures and documentation smoothly, facilitating delivery to your facility. We are equipped to handle the complexities of exporting large and heavy machinery components, ensuring compliance with international shipping regulations and standards. This global capability means that wherever your paper mill is located, you can rely on us for the supply of high-quality paper machine press rolls, including the ProRoll 5000 series, manufactured to your specifications and delivered on time. Our commitment to being a dependable global supplier underpins our reputation in the industry, built on trust and consistent performance, supporting both major industrial operations and smaller-scale paper producers with the same dedication to service excellence and reliable product delivery, ensuring extending lifespan of paper machine press rolls through quality manufacturing and timely supply.

Our relationship with our customers doesn't end with the delivery of the product. We provide comprehensive purchase and after-sales support to ensure you derive maximum value from your investment in our paper machine press rolls. For clients exploring options, we can discuss sample availability for cover materials or smaller components where feasible, allowing you to evaluate quality firsthand. We offer flexible order quantity options, accommodating everything from single units for urgent replacements to bulk orders for machine rebuilds. Our payment options are designed to be convenient and secure, accommodating various business practices (specific details discussed during quotation). Beyond the initial purchase, our technical support team is available to provide guidance on installation procedures, alignment, and initial start-up to ensure the rolls perform optimally from day one. We offer advice on recommended maintenance practices for paper machine press rolls, helping your team implement effective preventative measures to maximize service life. In the unlikely event of issues, our support team can assist with troubleshooting and diagnosing potential problems. We also facilitate the supply of spare parts, such as bearings or seals, relevant to the roll assembly. Our aim is to be a long-term partner in your paper production success, providing not just components, but also the expertise and support necessary to keep your press section running smoothly and efficiently, leveraging the capabilities of advanced paper machine press rolls like the ProRoll 5000 to optimize your operations.

In conclusion, the performance of your paper machine press section is intrinsically linked to the quality and precision of its press rolls. As a professional paper machine press rolls manufacturer and global supplier, we are dedicated to providing solutions that meet the stringent demands of modern papermaking. From our advanced ProRoll 5000 series to fully customized rolls tailored to unique applications, we combine cutting-edge engineering, meticulous manufacturing processes, and rigorous quality control to produce rolls that deliver superior dewatering efficiency, exceptional durability, and reliable performance. Our capabilities extend to supporting both large business wholesale needs and individual purchase requirements, offering flexible customization options, and ensuring prompt and secure global delivery. We understand the importance of optimizing paper machine press section efficiency and extending lifespan of paper machine press rolls, and our products are designed with these critical goals in mind. Choosing the right partner for your press roll needs is an investment in the future productivity and profitability of your paper mill. We are confident that our expertise, product quality, and comprehensive support make us that ideal partner, providing the high-performance paper machine press rolls necessary to keep your operations running at peak efficiency.

For more detailed information, please visit our official website: Paper machine press rolls