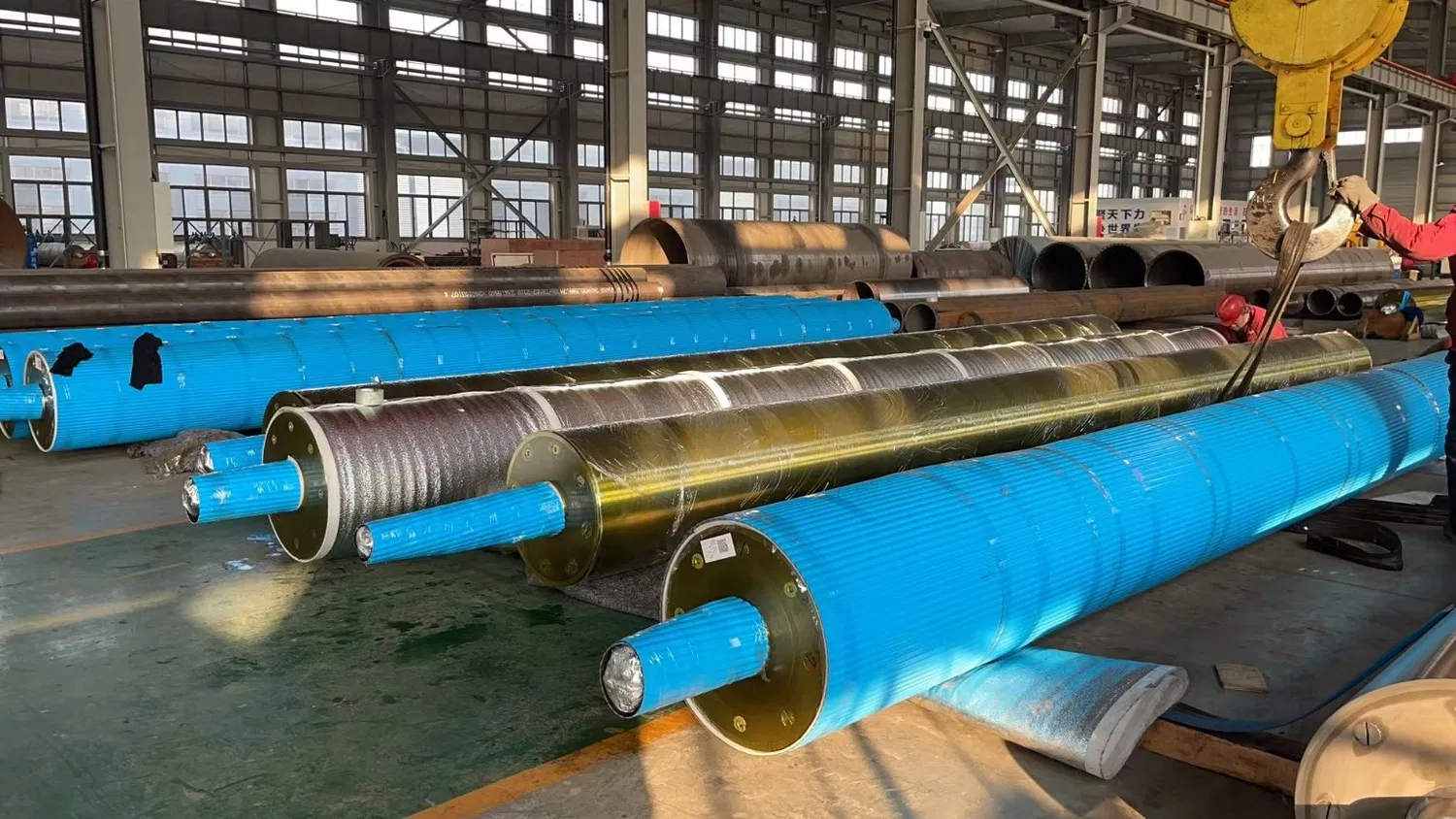

The paper manufacturing process is a complex symphony of machinery, and at its heart lie the paper machine rolls. These critical components are fundamental to nearly every stage, from forming the sheet to drying and finishing. The quality, precision, and reliability of these rolls directly impact production efficiency, paper quality, and operational costs. Therefore, identifying and partnering with leading paper machine roll manufacturers is not just a procurement decision; it's a strategic imperative for any successful paper mill. These top companies in the industry don't just supply parts; they provide engineered solutions built on decades of experience, advanced materials science, and a deep understanding of the papermaking process. Frankly speaking, the difference between an average roll and one from a leading manufacturer can translate into significant gains in uptime, reduced maintenance, and superior end-product characteristics. It's a high-stakes environment where precision engineering meets demanding operational conditions, making the choice of manufacturer absolutely crucial for competitiveness and profitability in the global paper market. Have you ever stopped to consider the immense forces and precise tolerances these rolls handle day in and day out?

The Critical Role of Paper Machine Rolls in Production Efficiency

Understanding the sheer importance of paper machine rolls helps clarify why the pedigree of the manufacturer matters so profoundly. These aren't just simple cylinders; they are highly engineered components performing specialized functions under extreme stress, temperature, and chemical exposure. Consider the press section, where rolls exert immense pressure to dewater the paper sheet – consistency and precise nip control are paramount. In the dryer section, rolls must efficiently transfer heat while enduring high temperatures and steam pressure, directly influencing drying rates and energy consumption. Calender rolls, responsible for final surface smoothness and thickness, require exceptional surface finishes and dimensional stability. A failure or even suboptimal performance in any of these rolls can lead to costly unscheduled downtime, web breaks, quality defects (like uneven profiles or surface blemishes), and increased energy usage. Top companies in the industry invest heavily in design, materials, and manufacturing processes specifically to mitigate these risks. Their rolls are built for longevity, consistent performance, and ease of maintenance, contributing directly to maximizing overall equipment effectiveness (OEE) and ensuring the paper mill operates like a well-oiled machine, quite literally. It’s worth noting that the initial investment in a high-quality roll from a leading manufacturer often yields substantial long-term savings through enhanced productivity and reduced operational headaches.

Identifying the Hallmarks of Leading Paper Machine Roll Manufacturers

So, what truly distinguishes the leading paper machine roll manufacturers from the rest? It's a combination of tangible capabilities and intangible qualities built over time. Firstly, technological expertise and engineering prowess are non-negotiable. This includes advanced design capabilities using Finite Element Analysis (FEA) to predict roll behavior under load, expertise in material science to select or develop alloys and coatings for specific applications (resisting wear, corrosion, heat), and state-of-the-art manufacturing facilities ensuring tight tolerances and consistent quality. Secondly, a commitment to research and development (R&D) is vital. Top companies continuously innovate, seeking new materials, improved roll cover compounds, enhanced internal structures (like advanced heating/cooling systems), and smarter roll designs (e.g., variable crown rolls) to meet evolving industry demands for higher speeds, wider machines, and diverse paper grades. Thirdly, stringent quality control throughout the manufacturing process, from raw material inspection to final dynamic balancing and dimensional checks, is fundamental. Many experts agree that robust quality assurance is a key differentiator. Lastly, comprehensive service and support, including installation assistance, maintenance recommendations, roll grinding services, and troubleshooting expertise, demonstrate a true partnership approach. These manufacturers understand they are providing a critical component and stand behind their product throughout its lifecycle.

Focus on Material Science and Coating Technologies

A deeper dive into the capabilities of leading manufacturers reveals a strong emphasis on material science and coating technologies. The base material of the roll shell, the journals, and the internal structure must be carefully selected based on the roll's position and function. This might involve specialized steels, stainless alloys, chilled iron, or even granite for specific applications. However, the roll surface, the interface with the paper sheet or felt/wire, is often where the most sophisticated technology lies. Leading manufacturers possess extensive knowledge of roll covers and coatings – be it rubber, polyurethane, composites, ceramics, or advanced thermal sprays like HVOF (High-Velocity Oxygen Fuel). Choosing the right cover involves balancing hardness, wear resistance, release properties, chemical resistance, thermal conductivity, and grindability. For instance, a press roll cover needs excellent dewatering and wear characteristics, while a calender roll coating might prioritize exceptional smoothness and heat resistance. Top companies often have proprietary cover formulations developed through intensive R&D, offering unique performance advantages tailored to specific paper grades or machine conditions. This deep understanding of materials and surface engineering is a core competency that directly translates into longer roll life, better paper quality, and improved machine runnability.

A Closer Look at Top Companies Shaping the Paper Machine Roll Industry

While naming specific companies can be fleeting, the characteristics defining the top companies in the industry remain consistent. These organizations typically possess a global footprint, serving major papermaking regions and understanding diverse market needs. They often offer a comprehensive portfolio covering various roll types – from forming rolls and press rolls to dryer cylinders, calender rolls, and reel spools – providing a single source for many mill requirements. However, specialization also marks leadership; some top companies might focus intensely on particular roll types or technologies, achieving unparalleled expertise in that niche, such as high-performance press roll covers or complex variable crown rolls. What unites them is a reputation built on reliability, performance, and innovation. They invest significantly in their facilities, workforce training, and customer relationships. Interestingly enough, many leading manufacturers actively collaborate with paper mills and machine builders to co-develop solutions for specific challenges, pushing the boundaries of papermaking technology. Their influence extends beyond simply supplying hardware; they contribute to setting industry standards and driving process improvements. When evaluating potential partners, looking for this blend of global reach, product breadth or specialized depth, and a proven track record of innovation and reliability is key to identifying a genuine industry leader.

Innovation and Technology Driven by Top Paper Machine Roll Manufacturers

Innovation is the lifeblood of progress in the paper industry, and leading paper machine roll manufacturers are often at the forefront of technological advancements. They understand that paper mills constantly strive for higher speeds, improved quality, reduced energy consumption, and enhanced sustainability – and roll technology plays a critical part in achieving these goals. Key areas of innovation include:

- Advanced Materials and Coatings: As mentioned, developing new alloys and cover materials that offer longer life, better wear resistance, improved heat transfer, or specific surface properties remains a major focus. Nanotechnology is also finding its way into coatings for enhanced performance.

- Intelligent Rolls: Integrating sensors into rolls to monitor parameters like temperature, vibration, pressure profiles, and cover condition in real-time is a growing trend. This data enables predictive maintenance, process optimization, and quicker troubleshooting, aligning with Industry 4.0 concepts.

- Energy Efficiency: Designing rolls, particularly dryer cylinders and heated calender rolls, for more efficient heat transfer reduces steam consumption, a significant operational cost. This might involve optimized internal designs or specialized surface treatments.

- Lightweight Designs: Exploring composite materials or optimized steel structures can reduce roll weight, potentially lowering drive power requirements and easing handling during maintenance.

- Sustainable Solutions: Developing longer-lasting rolls reduces the frequency of replacement and refurbishment, minimizing resource consumption. Innovations in roll cover materials that are easier to recycle or have a lower environmental footprint are also gaining traction. These innovations, driven by the top companies in the industry, provide tangible benefits to paper mills, helping them stay competitive and meet evolving market demands. Why is this continuous innovation so crucial? Because standing still in this industry means falling behind.

Navigating the Selection Process: Choosing the Right Manufacturer

Selecting a paper machine roll manufacturer is a decision with long-term consequences. How can a paper mill ensure they partner with one of the genuine leading paper machine roll manufacturers? It requires a thorough evaluation process beyond just comparing initial price tags. Key considerations should include the manufacturer's technical capabilities – do they possess the engineering depth to understand the specific application and recommend or design the optimal roll? Review their track record and request references from mills with similar machines or producing similar grades. Assess their manufacturing facilities and quality control procedures; ideally, this involves a plant visit or a detailed audit. In my experience, understanding their R&D commitment gives insight into their future capabilities and dedication to improvement. Equally important is the level of service and support offered – consider their responsiveness, field service capabilities, roll maintenance expertise (including grinding), and warranty terms. Don't underestimate the value of a collaborative relationship; a manufacturer willing to work closely with the mill to solve problems or optimize performance is invaluable. It’s crucial to weigh the total cost of ownership (TCO), factoring in expected roll life, maintenance requirements, impact on energy consumption, and potential effects on paper quality and machine uptime, rather than just the initial purchase price. What criteria does your mill prioritize when evaluating roll suppliers?

How Our Expertise Aligns with Leading Industry Standards

In the competitive landscape of paper machine roll supply, our company strives to embody the characteristics associated with the leading paper machine roll manufacturers. We understand the critical nature of these components and the trust placed in us by our clients. Our commitment begins with a deep dive into the specific operational context of each application, leveraging our engineering expertise to ensure the proposed roll solution is perfectly matched to the demands of the machine position and the paper grades being produced. We invest significantly in maintaining rigorous quality control throughout our manufacturing process, utilizing advanced machining and measurement technologies to guarantee precision and consistency, mirroring the practices of the top companies in the industry. Furthermore, we actively engage in exploring and implementing advanced materials and surface technologies, aiming to provide rolls that offer extended service life, enhanced performance, and contribute positively to our clients' operational efficiency. We believe that providing a high-quality, reliable roll is only part of the equation; offering responsive technical support and collaborating with mills to address challenges and optimize performance are equally vital aspects of our service philosophy. Our goal is not just to be a supplier but a trusted partner, delivering value that goes beyond the physical product itself and aligns with the high standards set by industry leaders.

Conclusion: The Enduring Importance of Partnering with Top Roll Manufacturers

In conclusion, the significance of paper machine rolls within the papermaking process cannot be overstated. They are the workhorses that directly influence productivity, quality, and profitability. Partnering with leading paper machine roll manufacturers provides access to superior engineering, advanced materials, cutting-edge innovation, and reliable performance – factors essential for navigating the competitive pressures of the modern paper industry. These top companies in the industry distinguish themselves through a potent combination of technical expertise, unwavering commitment to quality, continuous innovation, and comprehensive customer support. Selecting the right manufacturer involves a careful assessment of these factors, looking beyond the initial cost to the long-term value and reliability offered. As mills continue to push for greater efficiency and higher quality standards, the role of high-performance rolls supplied by leading manufacturers will only become more critical. Ultimately, investing in quality rolls from a reputable, leading manufacturer is an investment in the mill's future success. Have you considered how your current roll supplier measures up against these hallmarks of industry leadership?

For more detailed information, please visit our official website: Paper Machine Roll Manufacturers