Welcome to this comprehensive guide exploring the diverse world of paper machine rolls and their indispensable functions. Within the intricate process of papermaking, these cylindrical components are far more than simple rotating parts; they are the workhorses that shape, dewater, press, dry, and finish the paper sheet. Understanding the specific types of paper machine rolls and their designated roles is fundamental for anyone involved in paper production, maintenance, or machine design. From the initial formation of the wet web to the final winding of the jumbo roll, each roll is meticulously engineered for a particular task, contributing significantly to the final paper quality, machine efficiency, and operational stability. Frankly speaking, the performance of an entire multi-million dollar paper machine often hinges on the condition and suitability of its rolls. This guide aims to delve into the key categories of these critical components, shedding light on why certain rolls are used in specific sections and how their design directly impacts their function within the complex papermaking journey. Have you ever truly considered the engineering marvels rotating tirelessly within these massive machines?

Understanding the Critical Role of Paper Machine Rolls in Papermaking

Before diving into the specific types, it's crucial to appreciate the overarching significance of paper machine rolls. These components are the literal backbone of the papermaking process, providing support, transport, and processing for the delicate paper web from the headbox slurry to the final reel. Their functions are incredibly varied, ranging from facilitating drainage in the forming section, applying immense pressure for water removal in the press section, transferring heat for drying, to imparting smoothness and gloss in the calender section. It's worth noting that the interaction between the roll surface and the paper sheet (or the fabrics supporting it, like forming wires and press felts) is paramount. The material composition, surface characteristics (smooth, grooved, drilled), crown profile, and operational parameters (speed, pressure, temperature) of each roll are carefully selected and controlled to achieve specific outcomes. A failure or inefficiency in even a single roll can create bottlenecks, compromise paper quality characteristics like strength or uniformity, increase energy consumption, and lead to costly downtime. Therefore, a deep understanding of roll functions isn't just academic; it's essential for optimizing production, troubleshooting issues, and making informed decisions about maintenance and upgrades. Many experts agree that mastering roll technology is a key differentiator in competitive paper manufacturing.

Exploring the Broad Spectrum: Different Types of Paper Machine Rolls

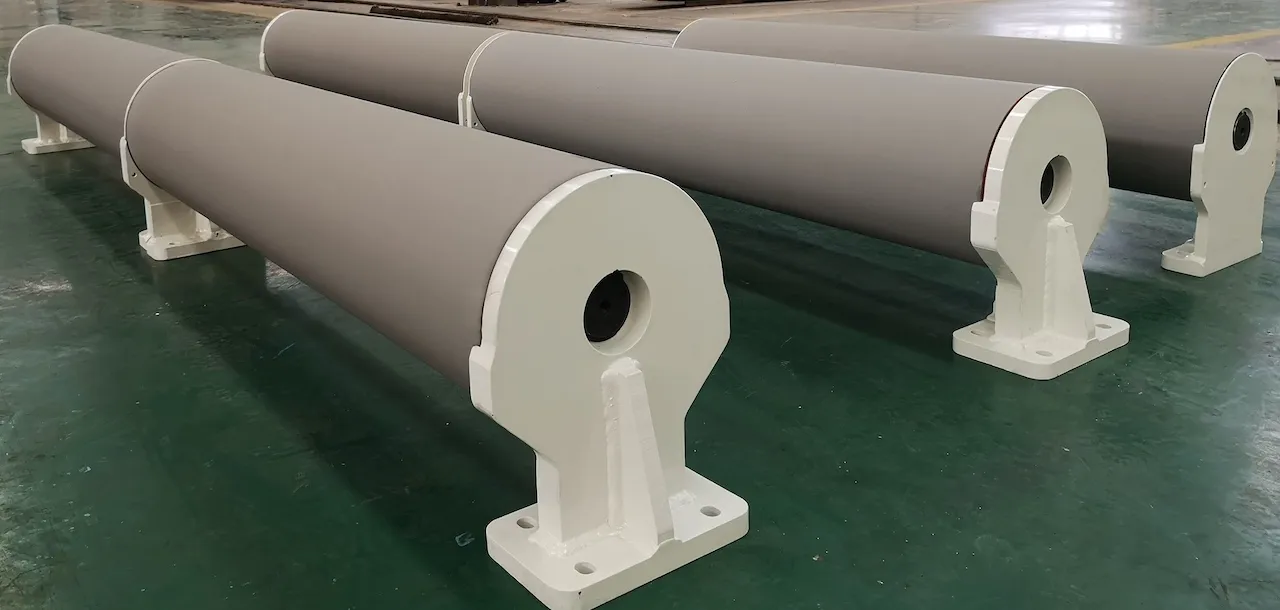

The sheer variety of types of paper machine rolls can seem daunting at first glance. Rolls can be categorized based on several criteria: their position within the paper machine (forming, press, dryer, calender, reel section), their core material (cast iron, steel, granite, composite materials), their cover material (rubber, polyurethane, composite, ceramic, metal coatings), their surface design (smooth, grooved, blind-drilled, suction-drilled), and their specific function. For instance, a roll in the press section designed for maximum water removal will look and behave very differently from a roll in the calender stack designed for imparting gloss. Interestingly enough, even within a single section, multiple distinct roll types often work in concert. The forming section might feature breast rolls, forming rolls, and couch rolls, each with unique designs and purposes. Similarly, the press section utilizes various combinations of plain, suction, grooved, or blind-drilled rolls depending on the paper grade and machine configuration. Understanding this classification system provides a framework for appreciating how each specific roll type contributes to the overall process, fulfilling its unique operational mandate derived directly from its design and placement. This diversity underscores the sophisticated engineering behind modern papermaking.

Roll Materials and Surface Engineering Dictate Function

Delving deeper into the types of paper machine rolls, the choice of core material and cover, along with surface engineering, is fundamental to their function. Core materials like ductile or cast iron are common for large dryer cylinders due to their heat transfer properties and structural integrity, while forged steel might be used for highly loaded press rolls requiring exceptional strength. Granite was historically used for some press rolls due to its hardness and water-repellency, though modern composites are increasingly favored for their lighter weight and tailored properties. Roll covers are equally critical. Rubber and polyurethane compounds, formulated for specific hardness (P&J) and chemical resistance, are ubiquitous in press sections, influencing nip characteristics and water removal. Advanced composite covers offer enhanced wear resistance and specific surface properties. Surface design is another crucial differentiator: smooth rolls provide even pressure, suction rolls (with internal vacuum boxes) actively pull water through perforations, grooved rolls provide channels for water escape under pressure, and blind-drilled rolls offer void volume without through-holes, balancing dewatering with sheet quality considerations. It's clear that the specific combination of material and surface design isn't arbitrary; it's a carefully engineered solution tailored to the precise paper machine roll functions required at each stage.

Key Functions Performed by Diverse Paper Machine Roll Types

The primary purpose of this guide is to illuminate the specific paper machine roll functions. Across the entire machine, rolls perform a continuum of tasks essential for transforming dilute fiber slurry into finished paper. In the initial forming section, rolls support the forming fabric, facilitate drainage of water through the fabric via gravity, suction, or induced pressure pulses, and ultimately help establish the sheet structure. Moving into the press section, the key function is mechanical dewatering – rolls create high-pressure nips (contact zones) that squeeze water out of the sheet and into press felts, significantly increasing the paper's solids content before it enters the energy-intensive dryer section. Here, large, heated dryer cylinders perform the function of evaporative drying, transferring thermal energy to evaporate the remaining water. Throughout the machine, guide rolls and felt rolls serve the critical function of steering and tensioning the fabrics (wires and felts) and the paper sheet itself, ensuring stable transport. Finally, in the finishing stages, calender rolls function to smooth the paper surface, control thickness (caliper), and impart gloss, while reel rolls ensure the paper is wound uniformly into large jumbo rolls for subsequent processing. Each function necessitates a specific roll design and operational approach.

Forming Section Rolls: Establishing the Paper Web

The forming section, or wet end, is where the paper sheet first takes shape, and several specialized roll types play pivotal roles. The Breast Roll is typically the first roll the forming fabric encounters after the headbox, supporting the fabric as the stock slurry is deposited. Its design influences initial drainage and fabric tension. Following this, a series of smaller diameter Forming Rolls or hydrofoils (though not rolls, they serve a similar dewatering function) are positioned beneath the forming fabric. These elements help to gently remove water through the fabric via induced vacuum or pressure pulses, aiding in fiber network formation without disrupting the nascent sheet. Perhaps the most critical roll in this section is the Couch Roll (pronounced "cooch"), located at the end of the forming section. Its primary function is to transfer the fragile, wet paper web from the forming fabric to the press section felt. Couch rolls are often large-diameter suction rolls, using internal vacuum to remove a significant amount of water and consolidate the sheet, making it strong enough for the transfer. The effectiveness of the couch roll directly impacts sheet properties and the water load entering the press section, highlighting the critical link between specific roll types and their targeted functions.

Press Section Rolls: Masters of Mechanical Dewatering

The press section's primary objective is efficient water removal through mechanical pressure, and its rolls are engineered specifically for this demanding function. This section typically consists of one or more nips formed by pairs of large, heavily loaded press rolls. Various types of paper machine rolls are employed here, often in combination. Suction Press Rolls feature drilled shells connected to an internal vacuum box, actively pulling water pressed from the sheet through the felt and into the roll's shell, preventing water from being reabsorbed by the sheet as it exits the nip. Blind-Drilled Rolls have holes drilled partway into the cover, creating void volume to accept water without the complexity of a vacuum system, often used in positions where sheet marking from through-drilled holes is a concern. Grooved Rolls have circumferential or helical grooves machined into their surface cover. These grooves provide channels for expressed water to escape the nip laterally, preventing hydraulic pressure buildup that could crush the sheet. Plain, smooth rolls are also used, often paired with a suction or vented roll. The configuration (number of presses, roll types used, nip pressures) is tailored to the paper grade being produced, optimizing the balance between water removal, energy efficiency, and preserving paper quality. To be honest, the press section is where clever roll design truly impacts the bottom line by reducing the energy needed for drying.

Drying Section Rolls: The Heat Transfer Specialists

Once the paper sheet leaves the press section, typically with 40-50% solids content, the remaining water must be removed through evaporation in the dryer section. The dominant players here are the Dryer Cylinders or dryer cans. These are large-diameter, hollow rolls, usually made of cast iron for its excellent heat conductivity and pressure vessel integrity. They function by being internally heated, most commonly with steam. The paper sheet, typically supported by dryer fabrics (felts), wraps around a significant portion of the cylinder's circumference, allowing heat to transfer from the hot roll surface through the sheet, evaporating the water. The efficiency of this heat transfer is critical for machine speed and energy consumption. Dryer sections often contain dozens of these cylinders arranged in upper and lower tiers. Alongside the main dryer cylinders are numerous Felt Rolls or Guide Rolls. While not directly involved in heat transfer, their function is essential: they support, guide, and tension the dryer fabrics, ensuring intimate contact between the paper sheet and the heated cylinders and maintaining proper sheet runnability through this long section. The synergy between the large dryer cylinders and the smaller guide rolls exemplifies how different roll functions are needed even within a single machine section.

Calender and Reel Rolls: Applying the Finishing Touches

After drying, the paper sheet proceeds to the finishing sections, primarily the calender and the reel, where the final set of specialized rolls performs crucial functions. The Calender Rolls work in stacks to modify the paper's surface properties. By passing the sheet through nips formed between hard (chilled iron) and/or soft (composite covered) rolls under controlled pressure and sometimes temperature, calendering improves smoothness, controls caliper (thickness), and can impart gloss. Different configurations exist, like machine calenders (hard nips) for density and smoothness, and soft calenders for bulk preservation and improved printability. The type and arrangement of calender rolls directly determine the final surface finish of the paper. Following calendering, the Reel Drum performs the function of winding the continuous sheet of paper into a large jumbo roll. It works in conjunction with a Reel Spool, upon which the paper accumulates. The reel drum often drives the winding process, ensuring a tightly and uniformly wound roll suitable for transport and subsequent converting processes like slitting or sheeting. Proper functioning of the reel is vital for preventing defects like wrinkles or bursts in the finished roll. Have you ever wondered how the subtle differences in calender roll materials achieve such varied paper finishes?

Optimizing Performance: Maintenance and Roll Cover Technology

Understanding the types and functions of paper machine rolls is incomplete without considering their maintenance and the technology that keeps them performing optimally. Rolls are subject to wear, corrosion, chemical attack, and potential damage from contaminants or operational upsets. Maintaining the correct roll shape (crown profile) is critical for uniform nip pressure distribution across the machine width, which directly impacts paper quality profiles (like moisture and caliper). This necessitates periodic roll grinding or recovering. The choice of roll cover material and its condition significantly influences performance – wear or damage can drastically reduce water removal efficiency in presses or cause surface defects in calendering. This is an area where our company excels; we provide advanced roll cover solutions and precision maintenance services designed to maximize roll lifespan and ensure consistent, high-quality paper production. Investing in high-performance covers tailored to specific applications, like enhanced abrasion resistance for challenging positions or optimized compounds for specific nip mechanics, can yield substantial returns through improved efficiency and reduced downtime. What challenges have you faced in maintaining optimal roll performance across different sections of your paper machine? Effective maintenance strategies, informed by a thorough understanding of each roll's function, are key to sustained papermaking success.

In conclusion, the world of paper machine rolls is complex and diverse, yet fundamentally logical. Each type of roll, whether in the forming, press, dryer, or finishing section, is meticulously designed to perform specific, critical functions that collectively transform raw fiber into high-quality paper. From the initial dewatering facilitated by forming and couch rolls, through the intensive mechanical squeezing in the press section, the evaporative work done by dryer cylinders, to the final surface refinement by calender rolls and winding onto the reel, these components are the heart of the papermaking machine. This comprehensive guide has aimed to illuminate the distinct roles played by various roll types, emphasizing how their materials, surface designs, and operational contexts dictate their function. Recognizing the importance of each roll and ensuring its optimal condition through proper selection and maintenance, potentially leveraging advanced solutions like those offered by our company, is paramount for achieving efficient, reliable, and high-quality paper production. The intricate dance of these rotating giants is truly central to the entire process.

For more detailed information, please visit our official website: Paper Machine Rolls